Preparing method for zinc-based super-hydrophobic surface with condensate liquid drop self-bounce character

A super-hydrophobic surface and condensate technology, applied to special surfaces, methods of granulating raw materials, pre-treated surfaces, etc., to achieve enhanced condensation heat transfer and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Clean the surface of the zinc sample with ethanol and deionized water in sequence, and dry it with nitrogen gas for later use.

[0020] (2) Soak the above-mentioned cleaned zinc sample in a low-temperature mixed solution with excess 0.5M zinc nitrate and 4.0M potassium hydroxide (the molar ratio of zinc nitrate and potassium hydroxide is 1:8) , deposited for 4 hours.

[0021] (3) Immerse the deposited zinc sample in an excess ethanol solution containing 1vol.% 1H,1H,2H,2H-perfluorodecyltriethoxysilane for 5 minutes, take it out and place it in an open environment at 120°C Heat treatment for 10 minutes.

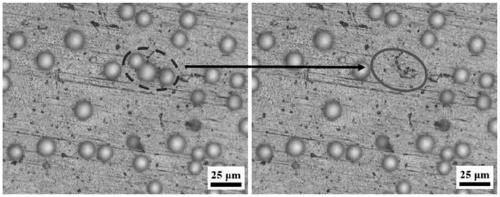

[0022] After treatment, the water drop contact angle photos on the surface of the obtained zinc sample are shown in figure 1 , the surface of the zinc sample exhibits superhydrophobic properties, with a contact angle of 169°. The merged condensate droplets will disappear from the superhydrophobic surface, demonstrating the occurrence of self-bouncing behavior, th...

Embodiment 2

[0024] (1) Clean the surface of the zinc sample with ethanol and deionized water in sequence, and dry it with nitrogen gas for later use.

[0025] (2) Soak the above-mentioned cleaned zinc sample in a low-temperature mixed solution with excess 0.5M zinc nitrate and 4.0M potassium hydroxide (the molar ratio of zinc nitrate and potassium hydroxide is 1:8) , deposited for 6 hours.

[0026] (3) Immerse the deposited zinc sample in an excess ethanol solution containing 1vol.% 1H,1H,2H,2H-perfluorodecyltriethoxysilane for 5 minutes, take it out and place it in an open environment at 120°C Heat treatment for 10 minutes.

[0027] After treatment, the surface of the obtained zinc sample exhibits superhydrophobic properties. The merged condensate droplets do not disappear from the superhydrophobic surface and remain on the superhydrophobic surface, proving that self-bouncing behavior does not occur.

[0028] The 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane can also be composed of tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com