Vacuum-poured multilayer hollow glass fiber reinforced plastic with high barrier property and production process

A vacuum infusion, high barrier technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of low structural strength, difficult construction of ground oil tanks, poor barrier properties, etc., to achieve good uniformity and reduce volatiles Outflow, the effect of improving barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

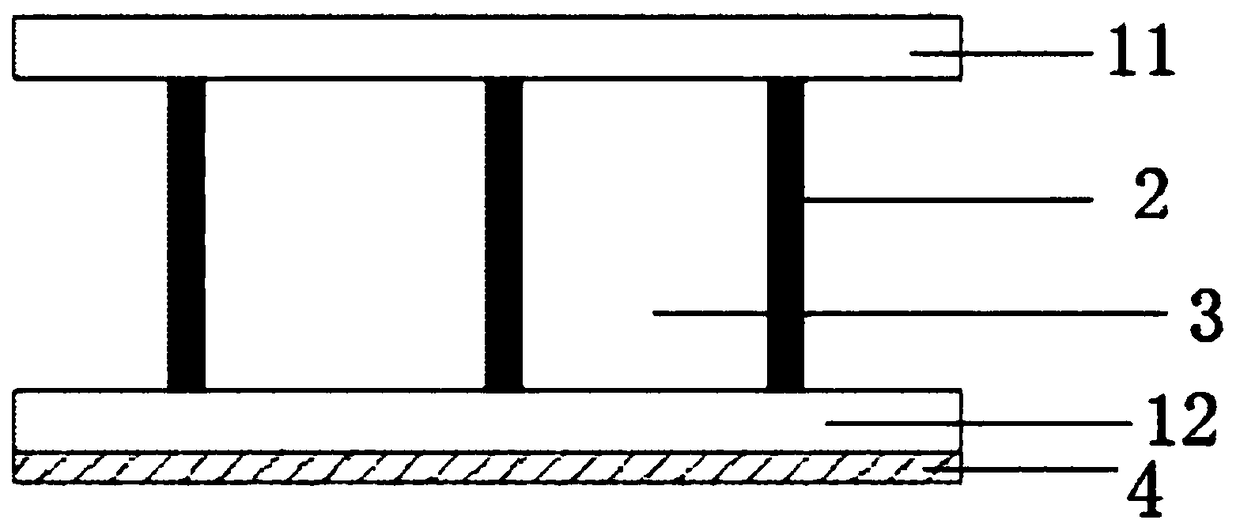

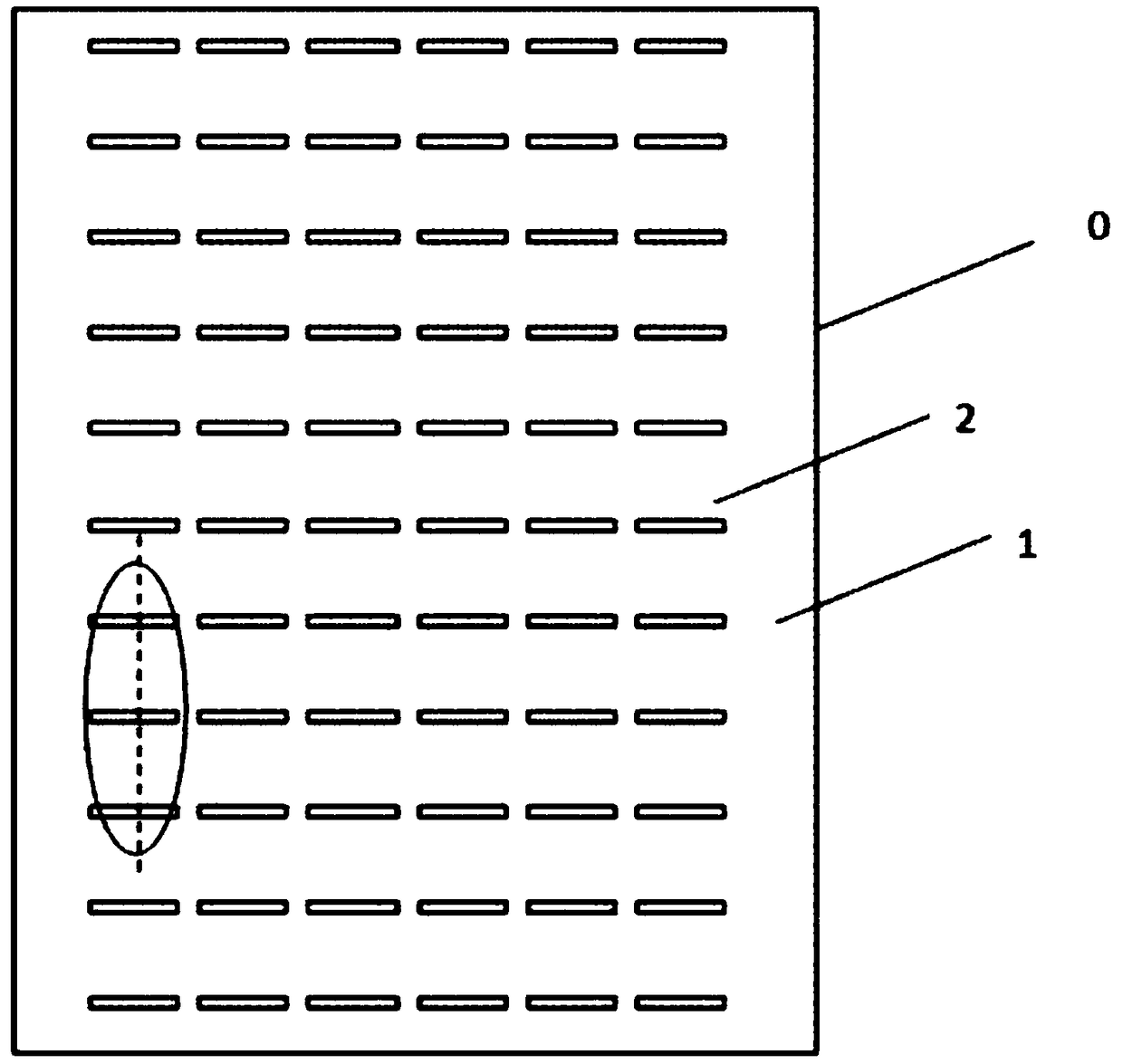

[0025] see figure 1 and 2 , providing a vacuum-infused multi-layer hollow FRP 0 with high barrier properties, including a first FRP layer 11 , a second FRP layer 12 , a resin-rich layer 4 and a support member 2 . The first FRP layer 11 and the second FRP layer 12 are FRP layers 1, forming a sealed chamber 3, and the sealed chamber 3 is a hollow structure. The resin-rich layer 4 is attached to one side of the second FRP layer 12 to form a FRP layer with the resin-rich layer 4 . The support member 2 is located in the sealed chamber 3 and divides the sealed chamber 3 into several spaces, and the several spaces are interconnected, and the support member 2 can improve strength.

[0026] The mass content of resin in the resin-rich layer 4 is greater than or equal to 75%, and the mass content of fibers in the resin-rich layer 4 is less than or equal to 25%. The resin is epoxy resin, phenolic resin, unsaturated polyester, urea-formaldehyde resin, polyvinyl alcohol, vinylidene chlor...

Embodiment 2

[0046] In order to manufacture reinforcing ribs with higher mechanical strength, on the basis of embodiment one, a process step is added between step 4 and step 5: a dry fiber layer is laid in the gap between the soluble and fusible intermediate layers, and the During infusion molding, the reinforcing rib of the pure resin matrix of the reinforcing rib embodiment 1 is improved into a reinforcing rib of fiber-reinforced resin, which greatly improves the mechanical strength of the embodiment 1, and its structural schematic diagram is the same as figure 1 same.

Embodiment 3

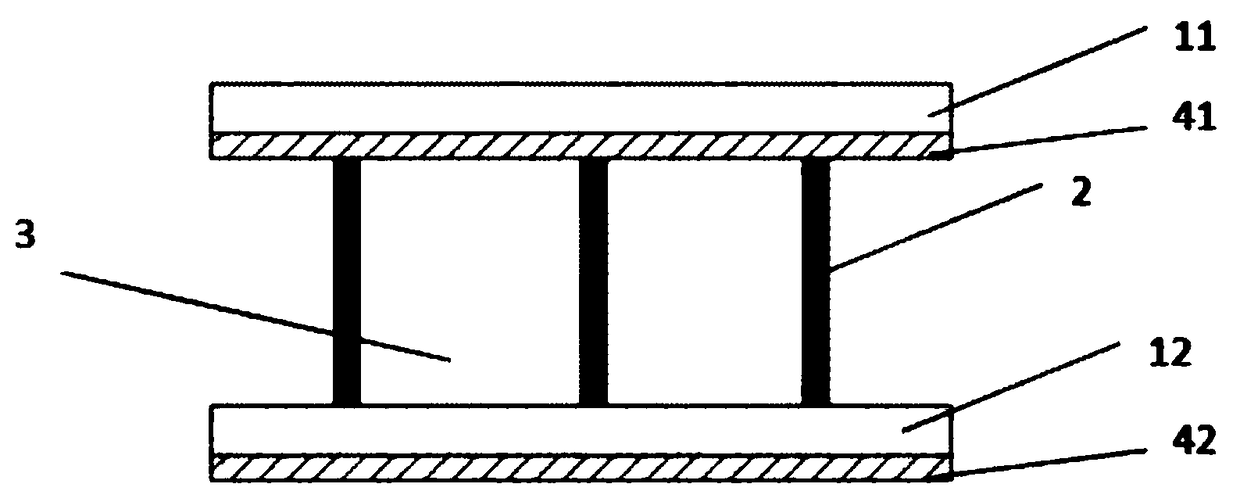

[0048] In order to further enhance the barrier properties of high-barrier double-layer hollow FRP, on the basis of Embodiment 1, a process step is added between step 3 and step 4: laying a fiber layer with a fluffy structure according to product requirements; and the lower surface of FRP 22 have a high barrier resin-rich layer, which improves the barrier properties of Embodiment 1 and improves the leak-proof performance of double-layer hollow FRP. For its structural diagram, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com