Delayed Vacuum Negative Pressure Environment-friendly Perforation Device for Compound Perforation

A technology of composite perforation and time delay device, which is applied in wellbore/well components, production fluids, earthwork drilling and other directions, can solve the problems of increasing construction procedures and construction difficulty, environmental pollution of well site, affecting negative pressure effect, etc. To achieve the effect of compact overall structure design, reduced labor intensity and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

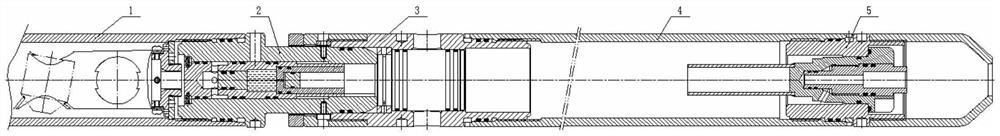

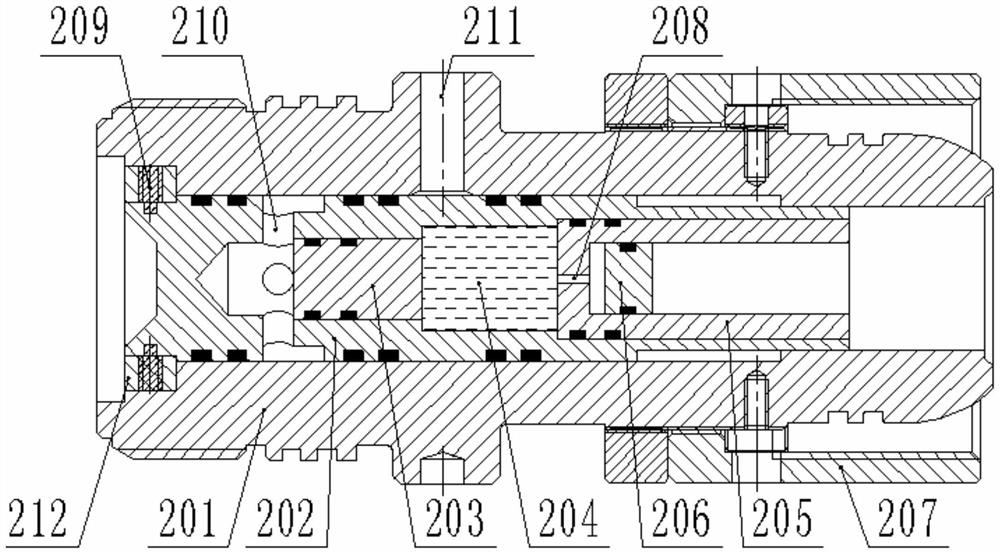

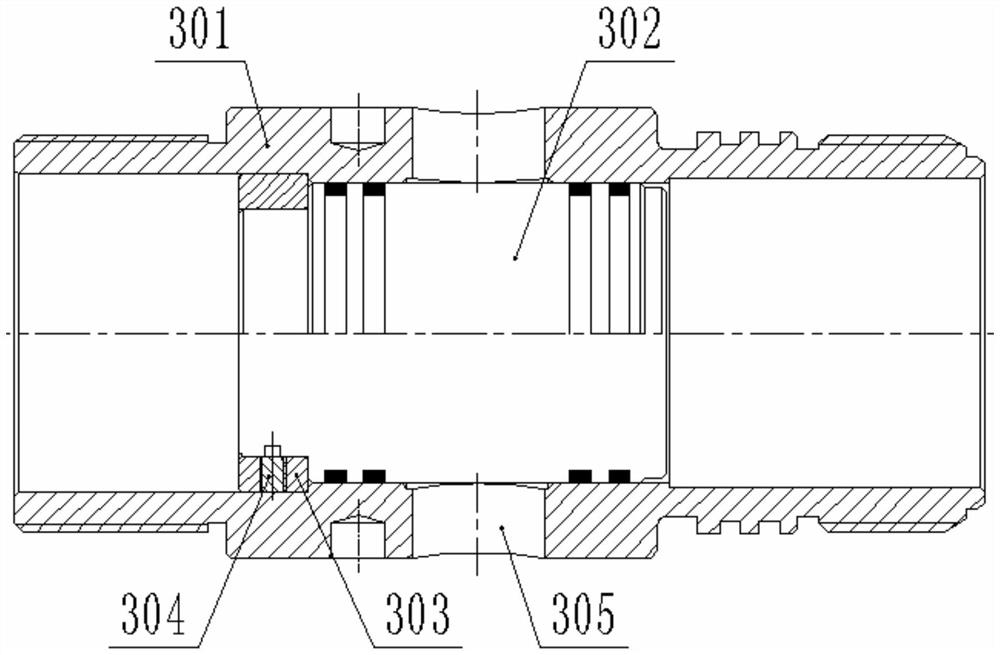

[0034] Such as figure 1As shown, the present invention includes composite perforating gun 1 and negative pressure gun, and composite perforating gun 1 and negative pressure gun all exist in the prior art, but the innovation of the present invention is: one is to negative pressure gun The structure has been improved, and the second is to increase the hydraulic delay device 2. After the assembly of the device is completed, the vacuum nozzle 503 on the tail 5 of the negative pressure environmental protection gun is docked with the vacuum pump, and the air in the negative pressure gun barrel 4 is drawn out by the vacuum pump, so that the pressure in the negative pressure gun barrel 4 reaches -0.098Mpa. During construction, the hydraulic delay device 2 of the device is connected to the lower end of the composite perforating gun 1 through a Tr90×4 thread. After perforating, lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com