Geopolymer gel material based on manganese slag and fly ash, and preparation method and application of geopolymer gel material

A technology of geopolymer and gel material, applied in the field of geopolymer gel material, can solve the problems of health hazards, waste of land, soil, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

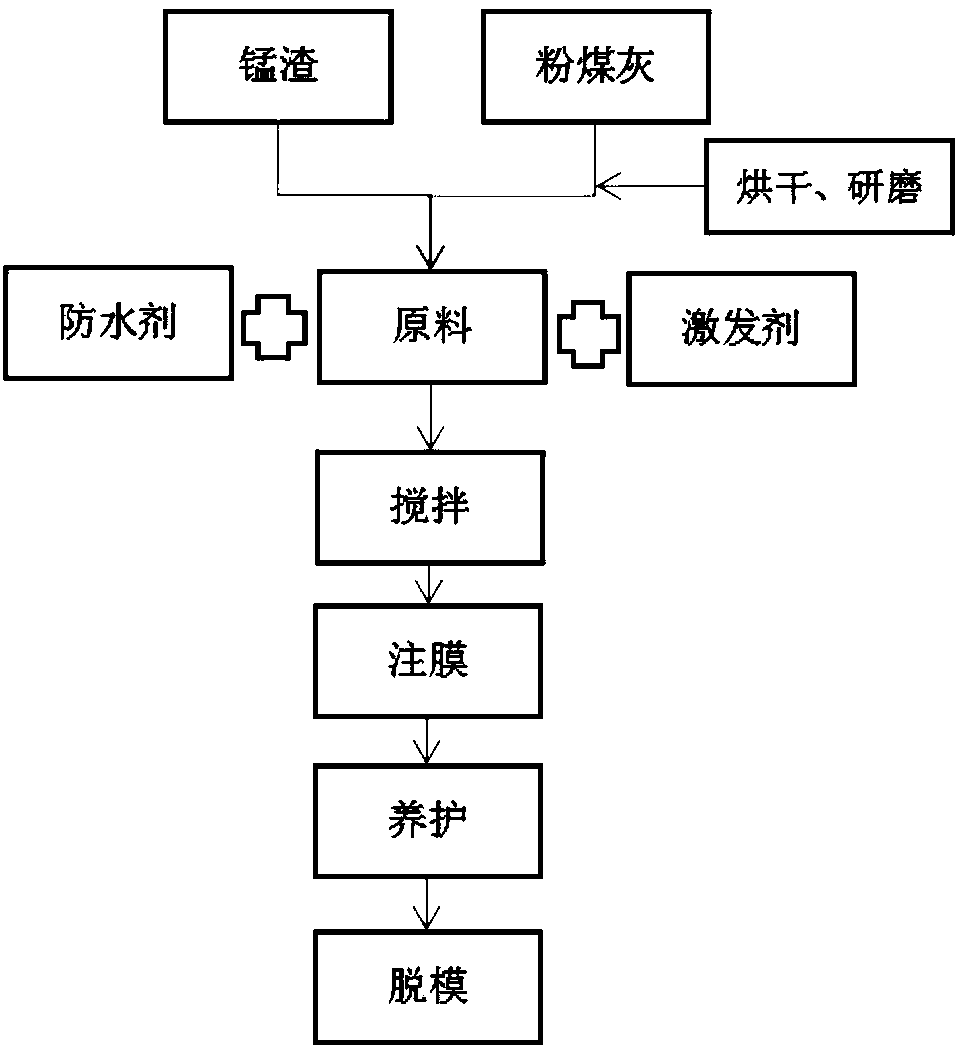

Method used

Image

Examples

Embodiment 1

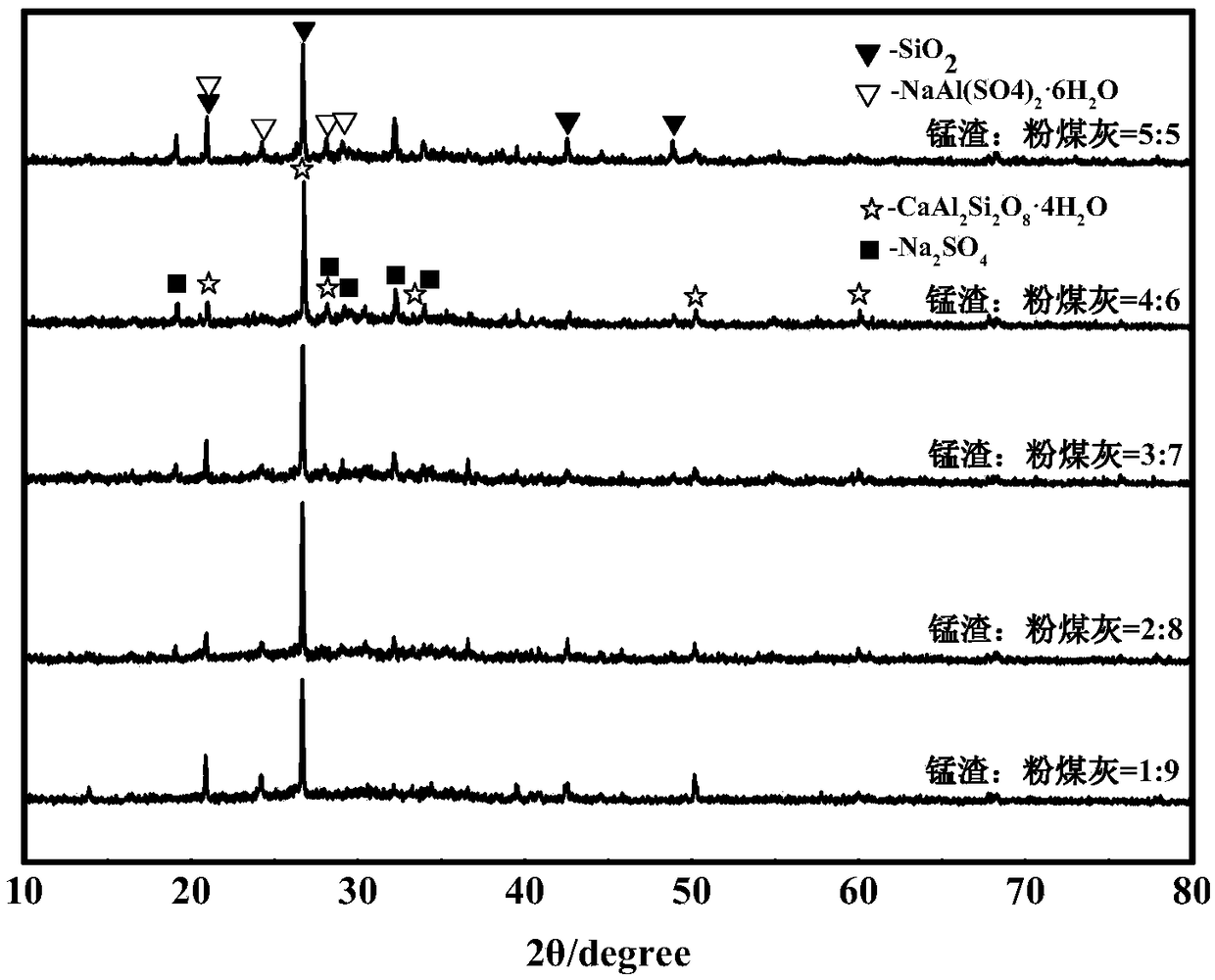

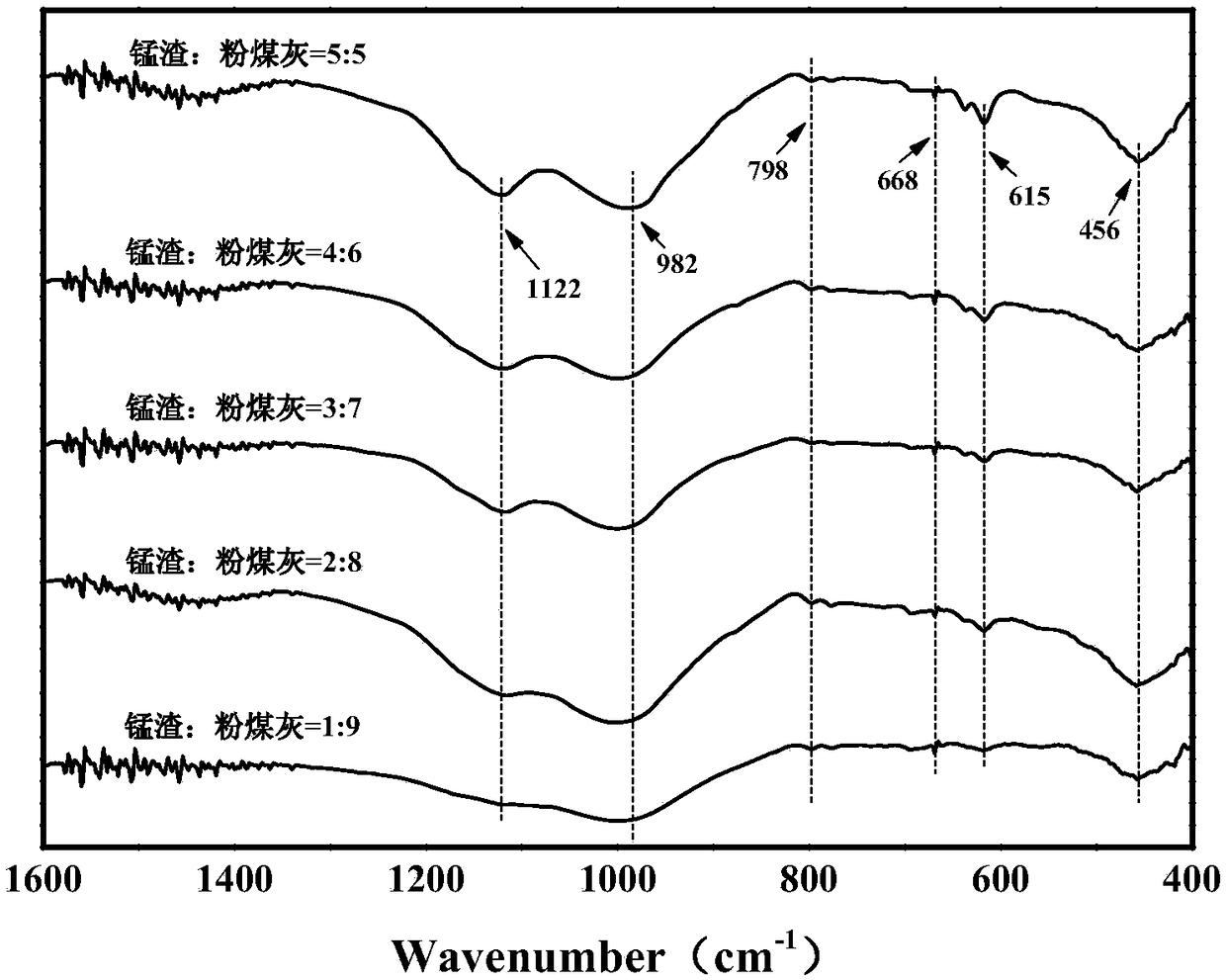

[0059] (1) Preparation of the mixed system of geopolymer gel material

[0060] First, the manganese slag and fly ash are mechanically ground to a particle size below 30 μm, and then the two are mixed evenly, wherein the weight ratio of manganese slag and fly ash is 1:9; 3wt% waterproofing agent, continue to stir, mix uniformly; Add activator aqueous solution, wherein, the add-on of activator accounts for 20wt% of the total weight of solid component and activator component, and the weight ratio of activator and water is 1.3:1, The weight ratio of NaOH and water glass in the activator is 2:1, and a mixture with a total amount of 2kg is prepared.

[0061] (2) Preparation of geopolymer gel material

[0062] Pour the mixed material into a 40mm×40mm×160mm triple mold, put it into a curing box, cure at a temperature of 80°C, and have a relative humidity of 25%. After curing for 12 hours, put it into 3d, 7d, and 14d to finally obtain manganese slag-powdered coal Ash-based geopolymer...

Embodiment 2

[0066] (1) Preparation of the mixed system of geopolymer gel material

[0067] First, the manganese slag and fly ash are mechanically ground to a particle size below 30 μm, and then the two are mixed evenly, wherein the weight ratio of manganese slag and fly ash is 2:8; 2wt% waterproofing agent, continue to stir, and mix uniformly; Add the aqueous solution of the activator, wherein the addition of the activator accounts for 20wt% of the total weight of the solid component and the activator component, and the weight ratio of the activator to water is 1.16:1, The weight ratio of NaOH and water glass in the activator is 2:1, and a mixture with a total amount of 2kg is prepared.

[0068] (2) Preparation of geopolymer gel material

[0069] With embodiment 1.

[0070] The compressive strength test was carried out, and the test results are listed in Table 5.

[0071] The gel material leaching toxicity test was carried out, and the test results are listed in Table 6.

Embodiment 3

[0073] (1) Preparation of the mixed system of geopolymer gel material

[0074] First, the manganese slag and fly ash are mechanically ground to a particle size below 30 μm, and then the two are mixed evenly, wherein the weight ratio of manganese slag and fly ash is 3:7; 2wt% waterproofing agent, continue to stir, and mix uniformly; Add the aqueous solution of the activator, wherein the addition of the activator accounts for 20wt% of the total weight of the solid component and the activator component, and the weight ratio of the activator to water is 1.16:1, The weight ratio of NaOH and water glass in the activator is 2:1, and a mixture with a total amount of 2kg is prepared.

[0075] (2) Preparation of geopolymer gel material

[0076] With embodiment 1.

[0077] The compressive strength test was carried out, and the test results are listed in Table 5.

[0078] The gel material leaching toxicity test was carried out, and the test results are listed in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com