Sleeve grouting material for connecting fiber reinforced steel bars and preparation method thereof

A technology of sleeve grouting and fiber reinforcement, which is applied in the field of building materials, can solve problems such as insufficient strength and toughness of grouting materials, failure of material structure, failure of mechanical structure, etc., and achieve the effect of good volume stability and high toughness in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

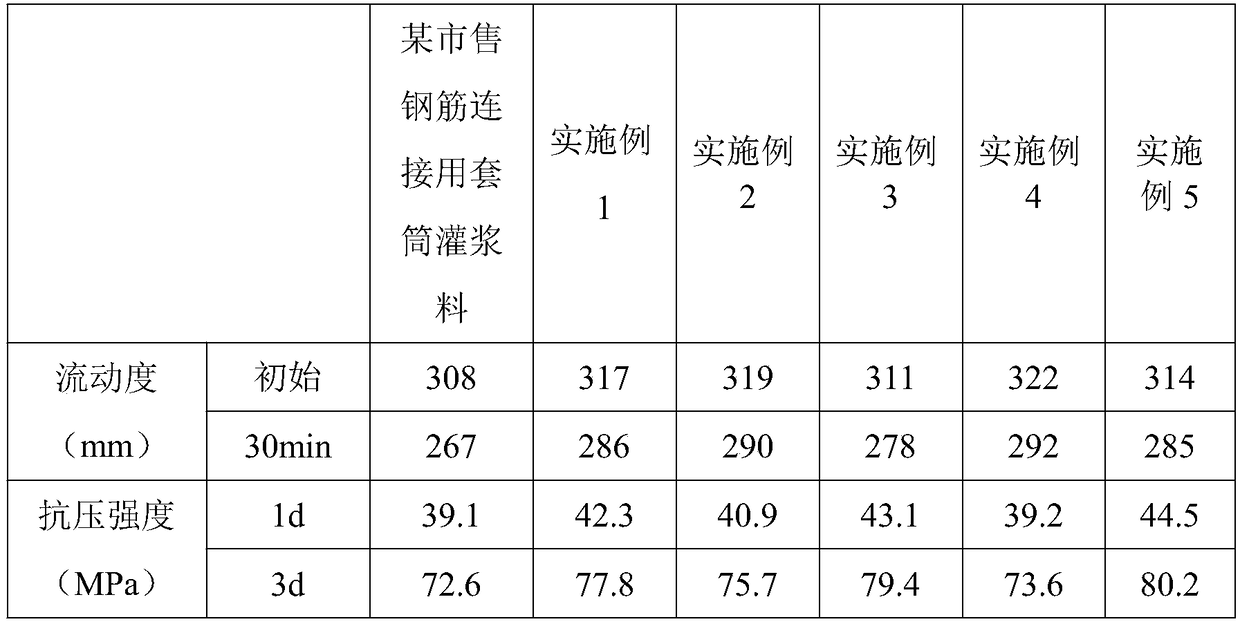

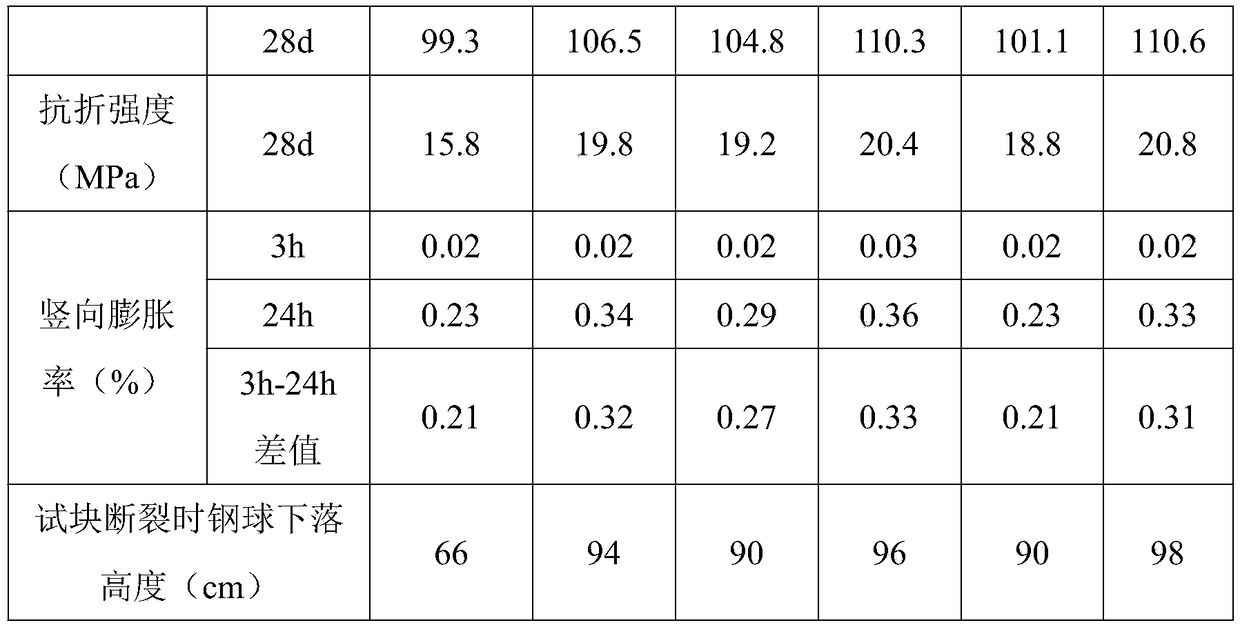

Examples

Embodiment 1

[0027] A sleeve grouting material for fiber-reinforced steel bar connection, consisting of the following materials: 400 parts of cement, 100 parts of admixture, 480 parts of sand, 1.5 parts of defoamer, 7 parts of composite water reducer, and 45 parts of composite retarder , 36 parts of composite expansion agent, 9 parts of composite early strength agent, 6.5 parts of composite fiber, 140 parts of water, in parts by weight.

[0028] Among them, the compounding ratio of cement is: 328 parts of 52.5 grade ordinary Portland cement, 48 parts of 52.5 grade sulphoaluminate cement, and 24 parts of 62.5 grade high alumina cement, calculated in parts by weight.

[0029] Among them, the compounding ratio of the admixture is: 40 parts of Class I fly ash, 25 parts of active silica fume, superfine brucite powder (d 97 =2um) 35 parts, in parts by weight.

[0030] Among them, the compounding ratio of sand is: 96 parts of 20-40 mesh quartz sand, 264 parts of 40-70 mesh dry sand, 120 parts of...

Embodiment 2

[0039] A sleeve grouting material for fiber-reinforced steel bar connection, consisting of the following materials: 395 parts of cement, 95 parts of admixture, 480 parts of sand, 1.5 parts of defoamer, 7 parts of composite water reducer, and 45 parts of composite retarder , 36 parts of composite expansion agent, 9 parts of composite early strength agent, 6.5 parts of composite fiber, 140 parts of water, in parts by weight.

[0040] Among them, the compounding ratio of cement is: 323.9 parts of 52.5 grade ordinary Portland cement, 47.4 parts of 52.5 grade sulphoaluminate cement, and 23.7 parts of 62.5 grade high alumina cement, calculated in parts by weight.

[0041] Among them, the compounding ratio of the admixture is: 38 parts of Class I fly ash, 23.75 parts of active silica fume, superfine brucite powder (d 97 =2um) 33.25 parts, in parts by weight.

[0042] Among them, the compounding ratio of sand is: 96 parts of 20-40 mesh quartz sand, 264 parts of 40-70 mesh dry sand, 1...

Embodiment 3

[0051] A sleeve grout for fiber-reinforced steel bar connections, consisting of the following materials: 410 parts of cement, 110 parts of admixtures, 480 parts of sand, 1.5 parts of defoaming agent, 7 parts of composite water reducer, and 45 parts of composite retarder , 36 parts of composite expansion agent, 9 parts of composite early strength agent, 6.5 parts of composite fiber, 140 parts of water, in parts by weight.

[0052] Among them, the compounding ratio of cement is: 336.2 parts of 52.5 grade ordinary portland cement, 49.2 parts of 52.5 grade sulphoaluminate cement, and 24.6 parts of 62.5 grade high alumina cement, calculated in parts by weight.

[0053] Among them, the compounding ratio of the admixture is: 44 parts of Class I fly ash, 27.5 parts of active silica fume, superfine brucite powder (d 97 =2um) 38.5 parts, in parts by weight.

[0054] Among them, the compounding ratio of sand is: 96 parts of 20-40 mesh quartz sand, 264 parts of 40-70 mesh dry sand, 120 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com