Water-based debinding binder used for ceramic injection moulding

A ceramic injection and binder technology, applied in the field of ceramic injection molding, can solve the problems of environmental pollution, operator poisoning, etc., and achieve the effects of safe recycling, high yield and low deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

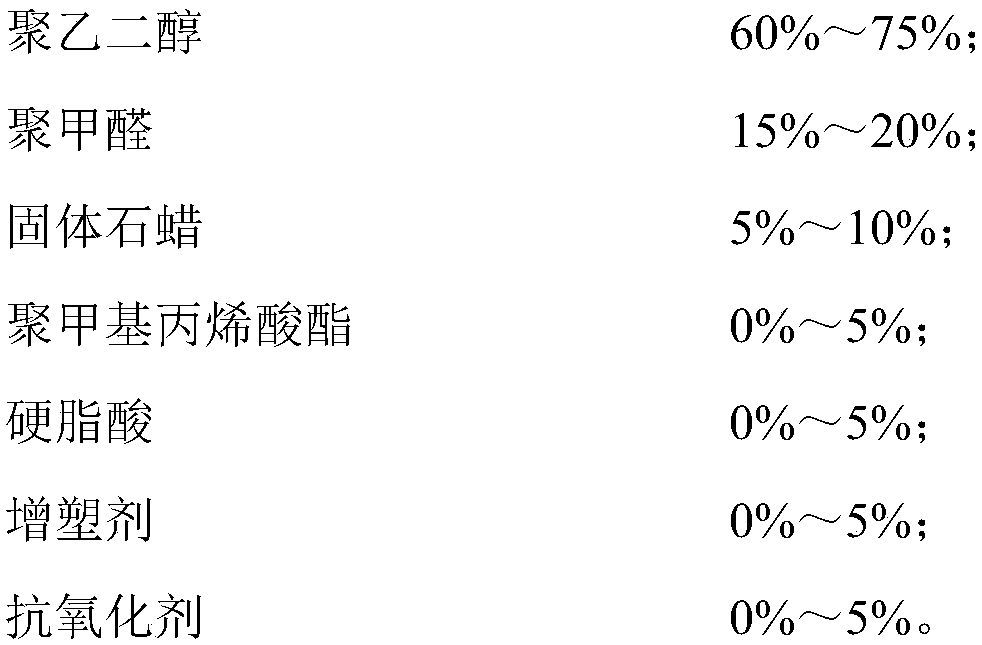

[0026] A water-based degreasing binder for ceramic injection molding, which consists of the following components by weight percentage:

[0027]

[0028] The polyethylene glycol is composed of 15% by weight of PEG600, 30% of PEG1000 and 55% of PEG1500.

[0029] A ceramic injection molding method:

[0030] (1) Mixing and granulation: the water-based degreasing binder ceramic powder prepared in this embodiment is subjected to high-temperature banburying to prepare ceramic feed;

[0031] (2) Injection molding: Injection molding the above-mentioned ceramic feed material to prepare a ceramic injection green body;

[0032] (3) Degreasing and sintering: put the ceramic injection green body into water for degreasing, and then put it into a sintering furnace for sintering to obtain a finished product.

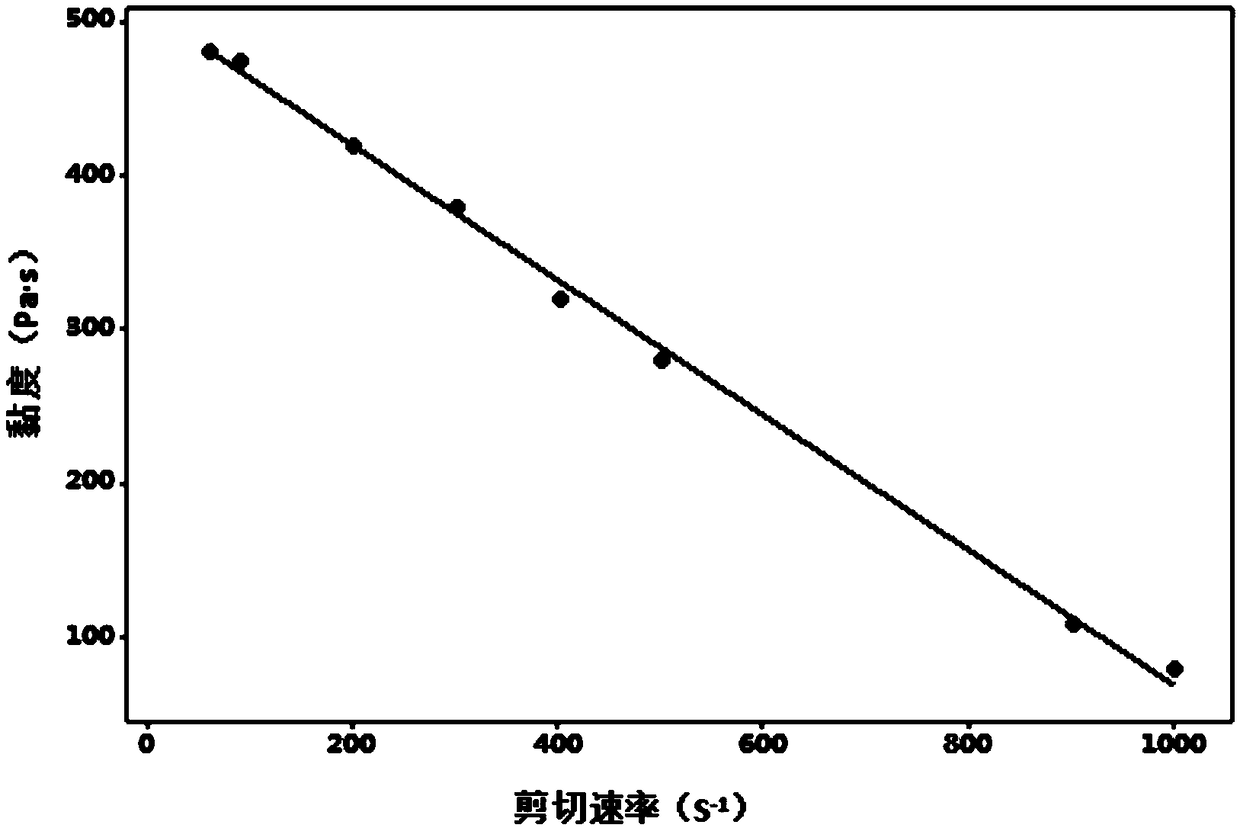

[0033] The rheological curve of the ceramic feeding material that measurement step (1) prepares, such as figure 1 As shown, the curve shows that the ceramic feed is a pseudoplastic...

Embodiment 2

[0037] A water-based degreasing binder for ceramic injection molding, which consists of the following components by weight percentage:

[0038]

[0039] The polyethylene glycol is composed of 20% by weight of PEG600, 35% of PEG1000 and 45% of PEG1500.

[0040] A ceramic injection molding method:

[0041] (1) Mixing and granulation: the water-based degreasing binder ceramic powder prepared in this embodiment is subjected to high-temperature banburying to prepare ceramic feed;

[0042] (2) Injection molding: Injection molding the above-mentioned ceramic feed material to prepare a ceramic injection green body;

[0043] (3) Degreasing and sintering: put the ceramic injection green body into water for degreasing, and then put it into a sintering furnace for sintering to obtain a finished product.

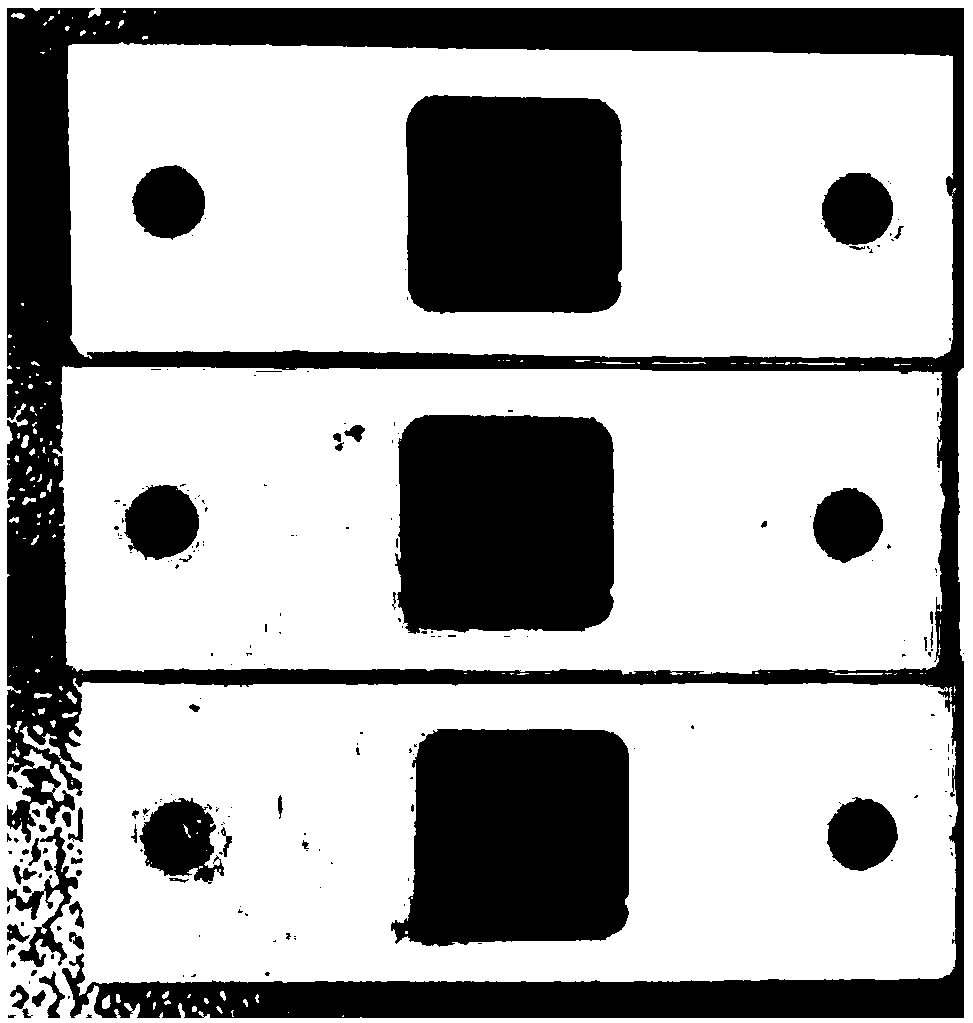

[0044] According to statistics, the yield of the finished product obtained after degreasing and sintering in step (3) reaches 98.6%, and phenomena such as product collapse and defor...

Embodiment 3

[0046] A water-based degreasing binder for ceramic injection molding, which consists of the following components by weight percentage:

[0047] Polyethylene glycol 70%;

[0048] POM 20%;

[0049] Paraffin wax 10%.

[0050] The polyethylene glycol is composed of 15% by weight of PEG600, 30% of PEG1000 and 55% of PEG1500.

[0051] A ceramic injection molding method:

[0052] (1) Mixing and granulation: the water-based degreasing binder ceramic powder prepared in this embodiment is subjected to high-temperature banburying to prepare ceramic feed;

[0053] (2) Injection molding: Injection molding the above-mentioned ceramic feed material to prepare a ceramic injection green body;

[0054] (3) Degreasing and sintering: put the ceramic injection green body into water for degreasing, and then put it into a sintering furnace for sintering to obtain a finished product.

[0055] According to statistics, the yield of the finished product obtained after degreasing and sintering in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com