Polyvinyl chloride foam material and preparation method thereof

A foaming material, polyvinyl chloride technology, applied in the field of polyvinyl chloride foaming material and its preparation, can solve the problems of high degree of polymerization of adipic acid polyester oil, low degree of polymerization of plasticizer, exceeding the test index, etc. Achieve the effect of large market prospect, uniform coloring, and not easy to precipitate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of this kind of polyvinyl chloride foam material simultaneously, comprises the following steps:

[0034] 1) Stir the polyvinyl chloride paste resin and filler to control the viscosity to 30000-50000mPa·s;

[0035] 2) Adipic acid polyester oil, foaming agent, and potassium-zinc stabilizer are stirred at a frequency of 25-35 Hz, and the material obtained in step 1) is poured into;

[0036] 3) Increase the stirring speed by 10Hz, add viscosity reducer after stirring, until the viscosity is 3000-5000mPa·s;

[0037] 4) Soak the toner and adipic acid polyester oil in a weight ratio of 1:0.5-0.7, and add to the feed liquid in step 3);

[0038] 5) Put the material liquid obtained in step 4) on the foaming coating table, and pass through five steam chambers with temperatures of 225±2°C, 220±2°C, 210±2°C, 205±2°C and 130±2°C in sequence. The bubble area is cooled by a cooling roller to obtain a polyvinyl chloride foam m...

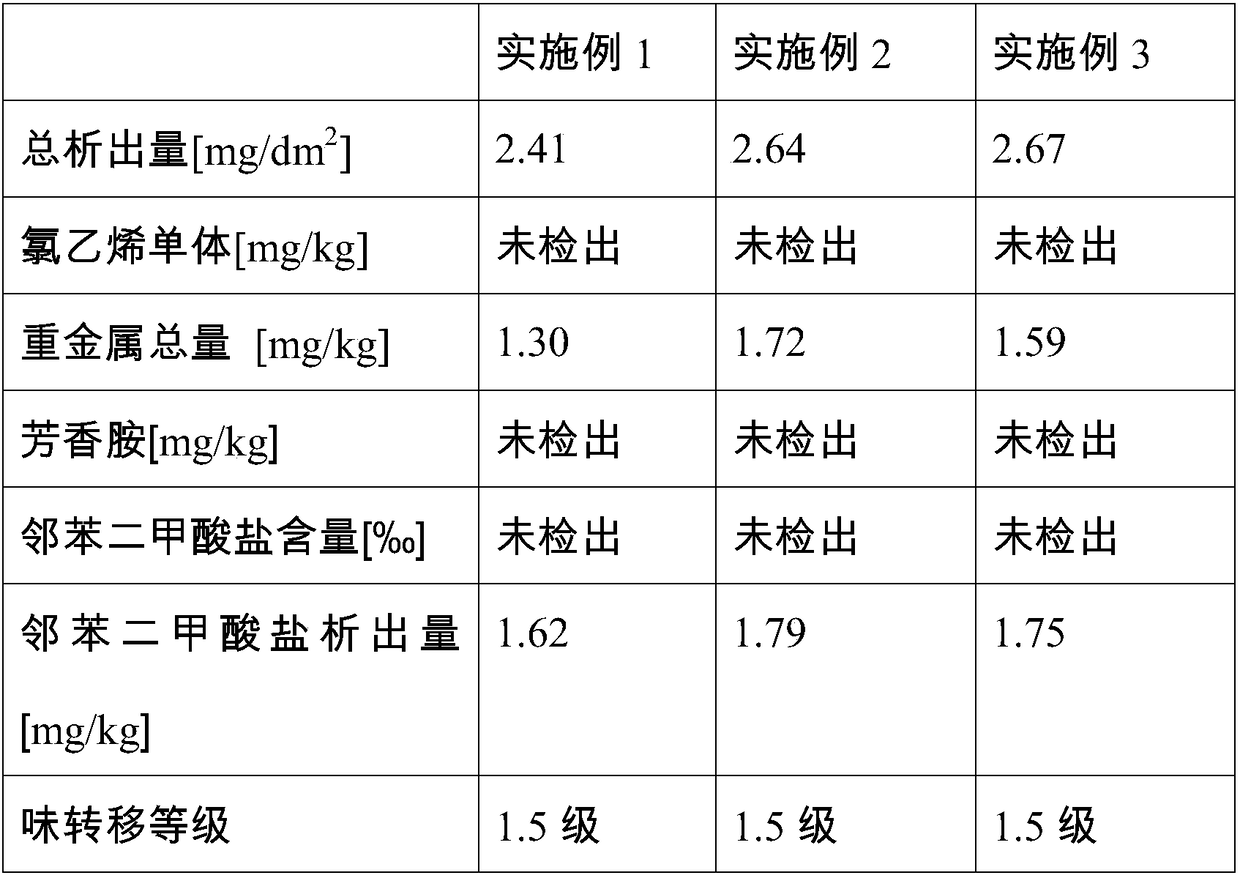

Embodiment 1

[0049] A polyvinyl chloride foaming material, which is made of the following components by weight: 35 parts of polyvinyl chloride paste resin, 25 parts of adipic acid polyester oil, 26 parts of filler, 7 parts of viscosity reducer , 3.5 parts of blowing agent, 0.7 part of potassium zinc stabilizer and 0.08 part of toner;

[0050] The method for preparing this polyvinyl chloride foam material may further comprise the steps:

[0051] 1) Stir the polyvinyl chloride paste resin and filler in the formula amount, and the viscosity is 41500mPa·s after stirring for 10 minutes;

[0052] 2) Adipic acid polyester oil, foaming agent, and potassium-zinc stabilizer are stirred at a frequency of 30 Hz, and the material obtained in step 1) is poured in at a flow rate of 10 wt % / min; The mixture of ethylene paste resin and filler is 10% of the total mass of raw materials in the kettle;

[0053] 3) Increase the stirring speed by 10Hz, add the viscosity reducer at a speed of 10wt% / min while st...

Embodiment 2

[0057] A polyvinyl chloride foaming material, which is made of the following components by weight: 25 parts of polyvinyl chloride paste resin, 30 parts of adipic acid polyester oil, 30 parts of filler, 9 parts of viscosity reducer , 2.5 parts of blowing agent, 0.5 part of potassium zinc stabilizer and 0.05 part of toner;

[0058] The method for preparing this polyvinyl chloride foam material may further comprise the steps:

[0059] 1) Stir the polyvinyl chloride paste resin and filler in the formula amount, and the viscosity is 34500mPa·s after stirring for 10 minutes;

[0060] 2) Adipic acid polyester oil, foaming agent, and potassium-zinc stabilizer are stirred at a frequency of 30 Hz, and the material obtained in step 1) is poured in at a flow rate of 15 wt % / min;

[0061] 3) Increase the stirring speed by 10Hz, add the viscosity reducer at a speed of 10wt% / min while stirring, and after stirring for 15min, the detected viscosity is 3600mPa·s;

[0062] 4) Soak the toner an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com