Polishing liquid and preparation method thereof

A technology of polishing liquid and solution, which is applied in the field of polishing and can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

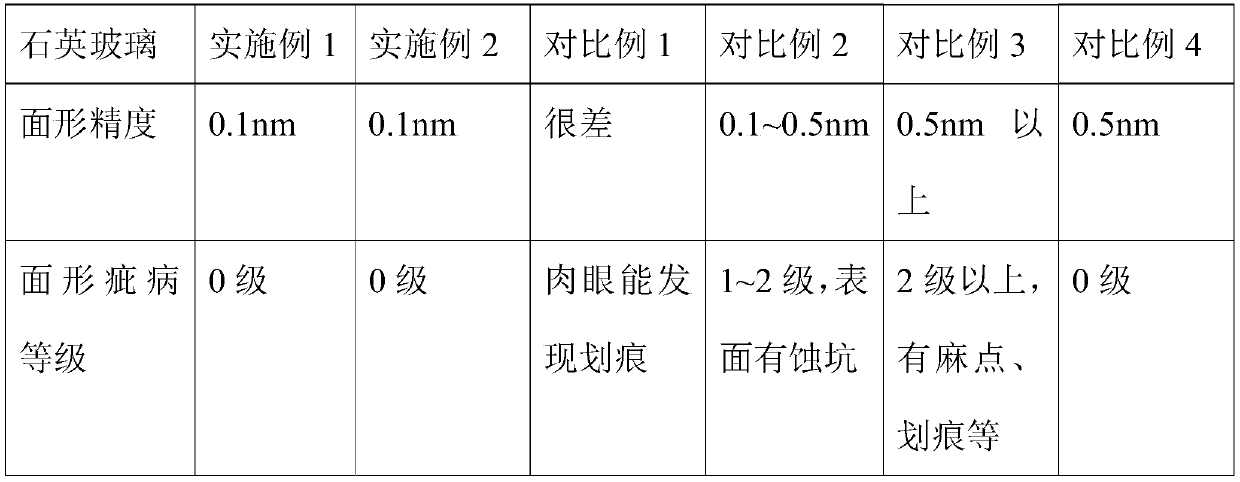

Examples

preparation example Construction

[0021] A method for preparing a polishing liquid in an embodiment includes the following steps S110-S140:

[0022] S110, providing the following raw materials: 4.5-5 parts by weight of zinc salt, 100 parts by weight of water and 20-35 parts by weight of cerium oxide.

[0023] Wherein, the zinc salt is selected from at least one of zinc nitrate, zinc sulfate and zinc chloride.

[0024] In this embodiment, the zinc salt is zinc nitrate.

[0025] Further, the particle diameter of cerium oxide is 200 mesh to 500 mesh.

[0026] In this embodiment, the particle size of cerium oxide is 200 mesh, 300 mesh, 400 mesh or 500 mesh.

[0027] By reasonably setting the ratio of zinc salt, water and cerium oxide, a polishing solution with a pH value of 5.5-6 can be obtained, and the pH value of the polishing solution is controlled at 5.5-6. The mechanical and chemical effects of the polishing solution on quartz glass can reach An equivalent state, at this time, the uniformity of chemical a...

Embodiment 1

[0037] Add 5 parts of zinc nitrate to 100 parts of water, and heat to 141°C while stirring until the zinc nitrate is completely dissolved to obtain a zinc nitrate solution. The zinc nitrate solution was left to stand for more than 4 hours, heated to 30°C, and filtered five times, and the pH value of the filtrate was tested to be about 5.1.

[0038] Add the filtrate to 35 parts of cerium oxide, stir once every 3 hours, repeat four times, and test its pH value to be about 6 after standing still.

Embodiment 2

[0040] Add 4.5 parts of zinc sulfate to 100 parts of water, and heat to 131°C while stirring until the zinc sulfate is completely dissolved to obtain a zinc sulfate solution. The zinc sulfate solution was left to stand for more than 4 hours, heated to 25°C, and filtered three times, and the pH value of the filtrate was tested to be about 5.1.

[0041] Add the filtrate to 20 parts of cerium oxide, stir once every 1 hour, repeat three times, and test its pH value to be about 5.6 after standing still.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com