A kind of ultra-high strength steel with near-net shape and its preparation method

An ultra-high-strength steel, near-net-shape technology, applied in the field of high-strength steel manufacturing, can solve the problems of affecting the surface quality of parts, unable to meet near-net-shape, low precision of formed parts, etc., to improve the forming qualification rate, excellent near-net shape Forming, the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

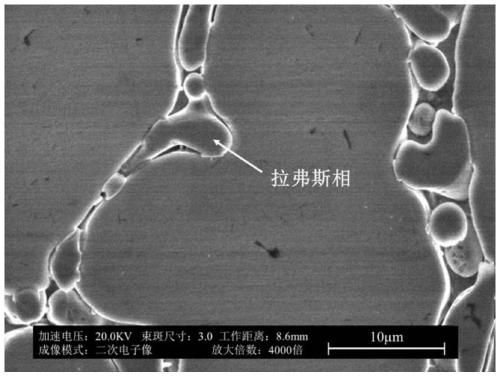

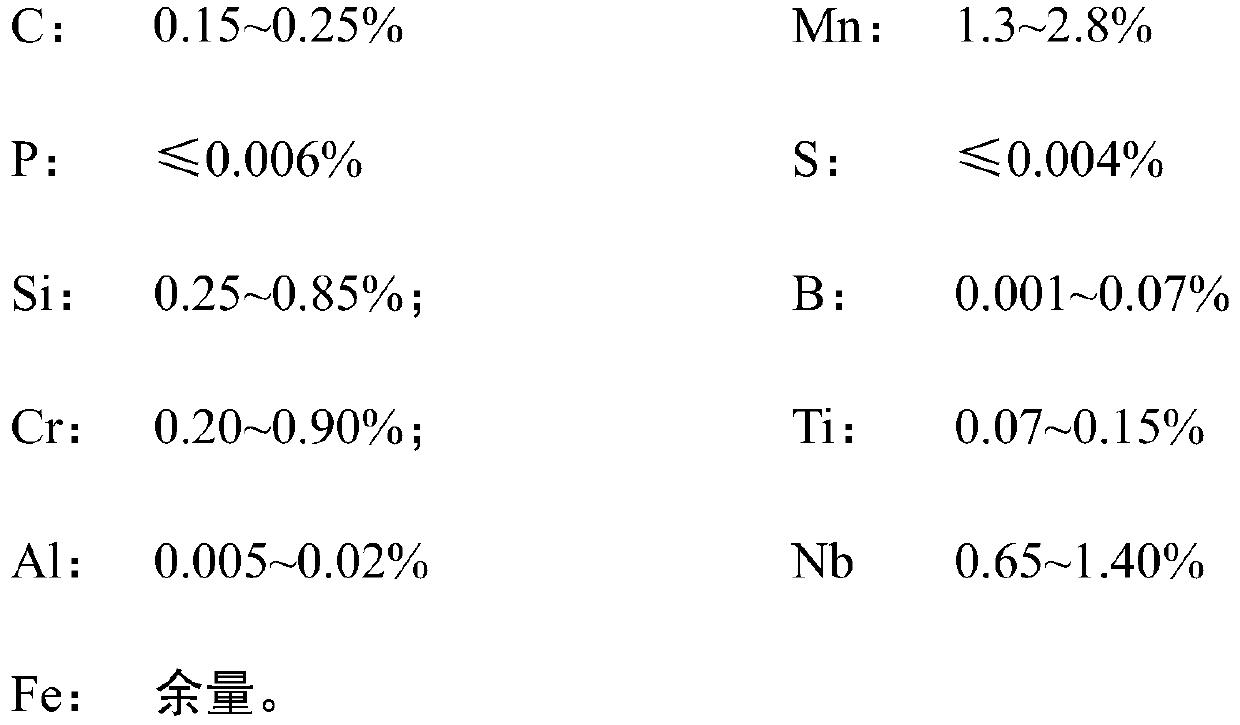

[0027] Such as figure 1 As shown, a kind of ultra-high-strength steel with near-net shape, according to the required requirements of ultra-high-strength steel with near-net shape, the preparation of ultra-high-strength steel with near-net shape includes the following mass percentages (wt.%) The components of:

[0028]

[0029] A method for preparing ultra-high-strength steel with near-net shape, the specific steps are as follows:

[0030] S1. Ingredients: weigh ingredients according to the above ratio;

[0031] S2. Alloy smelting: put the C, P, S, Si, B, Cr, Ti, Al and Fe elements weighed in step 1 into the crucible for vacuum induction melting. After the added elements are completely dissolved, start the magnetic stirring And continue smelting for 15 minutes; then stop heating for 10 seconds, then add Mn and Nb elements into the melt and continue heating for 10 minutes. Then stop heating, let the liquid alloy cool with the furnace, and pour it into the ingot mold when t...

Embodiment 2

[0036] Such as figure 1 As shown, a kind of ultra-high-strength steel with near-net shape, according to the required requirements of ultra-high-strength steel with near-net shape, the preparation of ultra-high-strength steel with near-net shape includes the following mass percentages (wt.%) The components of:

[0037]

[0038] A method for preparing ultra-high-strength steel with near-net shape, the specific steps are as follows:

[0039] S1. Ingredients: weigh ingredients according to the above ratio;

[0040] S2. Alloy smelting: put the C, P, S, Si, B, Cr, Ti, Al and Fe elements weighed in step 1 into the crucible for vacuum induction melting. After the added elements are completely dissolved, start the magnetic stirring And continue smelting for 18 minutes; then stop heating for 15 seconds, then add Mn and Nb elements into the melt and continue heating for 15 minutes. Then stop heating, let the liquid alloy cool with the furnace, and pour it into the ingot mold to for...

Embodiment 3

[0045] Such as figure 1 As shown, a kind of ultra-high-strength steel with near-net shape, according to the required requirements of ultra-high-strength steel with near-net shape, the preparation of ultra-high-strength steel with near-net shape includes the following mass percentage (wt.%) The components of:

[0046]

[0047] A method for preparing ultra-high-strength steel with near-net shape, the specific steps are as follows:

[0048] S1. Ingredients: weigh ingredients according to the above ratio;

[0049] S2. Alloy smelting: put the C, P, S, Si, B, Cr, Ti, Al and Fe elements weighed in step 1 into the crucible for vacuum induction melting. After the added elements are completely dissolved, start the magnetic stirring And continue the smelting time for 20min; then stop heating for 20s, then add Mn and Nb elements into the melt and continue heating for 20min. Then stop heating, let the liquid alloy cool with the furnace, and pour it into the ingot mold to form an allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com