Cold welding agent for building road and preparation method thereof

A road and construction technology, which is applied in the direction of adhesives, wax adhesives, adhesive types, etc., can solve the problems of fast cooling of road welding joint agents, failure to meet construction requirements, and easy cracking of caulking agents, etc., to achieve Improve the overall performance, excellent self-healing function, and overcome the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

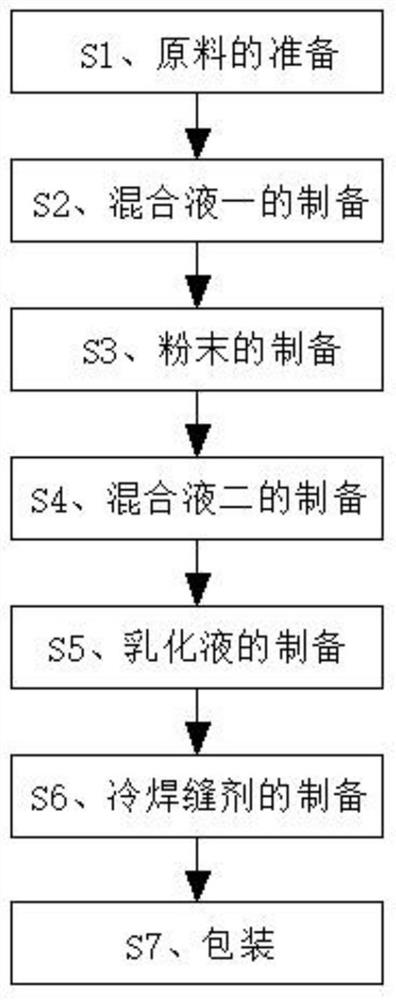

[0026] Example 1: Please refer to figure 1 , a cold welding agent for building roads, comprising the following parts by weight: 10 parts of cobalt oxide and high cobalt oxide, 10 parts of organic solvent, 6 parts of flocculant, 3 parts of stabilizer, 10 parts of chlorinated paraffin, 50 parts of base asphalt parts, 0.5 parts of crosslinking agent, 8 parts of emulsifier, 10 parts of 2-ethyl-4-methylimidazole, 15 parts of fiber and 50 parts of water.

[0027] A preparation method for cold welding agent for building roads, comprising the following steps:

[0028] S1. Preparation of raw materials: Weigh cobalt oxide, cobalt oxide, organic solvent, flocculant, stabilizer, chlorinated paraffin, matrix pitch, crosslinking agent, emulsifier, 2-ethyl-4 -Methylimidazole, fiber and water, standby;

[0029] S2. Preparation of mixed solution 1: put the base asphalt weighed in step S1 into a heating container for heating treatment at a heating temperature of 180°C, add water to the melted...

Embodiment 2

[0035] Example 2: Please refer to figure 1 , a cold welding agent for building roads, comprising the following parts by weight: 11 parts of cobalt oxide and high cobalt oxide, 15 parts of organic solvent, 7 parts of flocculant, 5 parts of stabilizer, 15 parts of chlorinated paraffin, 60 parts of base asphalt parts, 0.7 parts of crosslinking agent, 9 parts of emulsifier, 12 parts of 2-ethyl-4-methylimidazole, 18 parts of fiber and 55 parts of water.

[0036] A preparation method for cold welding agent for building roads, comprising the following steps:

[0037] S1. Preparation of raw materials: Weigh cobalt oxide, cobalt oxide, organic solvent, flocculant, stabilizer, chlorinated paraffin, matrix pitch, crosslinking agent, emulsifier, 2-ethyl-4 -Methylimidazole, fiber and water, standby;

[0038] S2. Preparation of mixed solution 1: put the base asphalt weighed in step S1 into a heating container for heating treatment at a heating temperature of 190°C, add water to the melted...

Embodiment 3

[0044] Example 3: Please refer to figure 1 , a cold welding agent for building roads, comprising the following parts by weight: 12 parts of cobalt oxide and cobalt oxide, 20 parts of organic solvent, 8 parts of flocculant, 8 parts of stabilizer, 20 parts of chlorinated paraffin, 70 parts of base asphalt 1 part, 1 part of crosslinking agent, 10 parts of emulsifier, 15 parts of 2-ethyl-4-methylimidazole, 20 parts of fiber and 60 parts of water.

[0045] A preparation method for cold welding agent for building roads, comprising the following steps:

[0046] S1. Preparation of raw materials: Weigh cobalt oxide, cobalt oxide, organic solvent, flocculant, stabilizer, chlorinated paraffin, matrix pitch, crosslinking agent, emulsifier, 2-ethyl-4 -Methylimidazole, fiber and water, standby;

[0047] S2. Preparation of mixed solution 1: put the base asphalt weighed in step S1 into a heating container for heating treatment at a heating temperature of 200°C, add water to the melted aspha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com