Comfortable antistatic fabric and preparation method thereof

An anti-static fabric, comfortable technology, applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of slow moisture dissipation, easy absorption of oil and dust, discomfort, etc., and achieve simple and efficient preparation methods, good moisture absorption and moisture conduction The effect of function and high market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

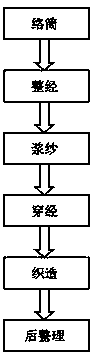

[0020] figure 1 It is the process step diagram of the preparation method of comfortable antistatic fabric in the embodiment of the present invention; the fabric is interwoven with 14.8tex warp and weft yarns and implanted with conductive filaments, and the warp and weft yarns are made of aloe modified viscose fiber and organic cotton For the blended yarn, the preparation method includes the following steps: a) winding, b) warping, c) sizing, d) drawing in, e) weaving, and f) finishing.

[0021] The comfortable anti-static fabric mentioned in the present invention uses 14.8tex aloe modified viscose fiber / organic cotton blended yarn as warp and weft yarn and implants conductive filaments. By optimizing the process parameters, the warp yarn density is 427 / 10cm and the weft yarn density is 268. Roots / 10cm intertwined. Among them, the blending ratio of the blended yarn is: 55% of aloe modified viscose fiber and 45% of organic cotton. The aloe-modified viscose fiber in the blended...

Embodiment

[0023] The specific preparation method is as follows:

[0024] a) Winding, adopt NO.21 C type automatic winder, wind the 14.8tex aloe modified viscose fiber / organic cotton blended yarn according to the process principle of medium speed, small tension and hairiness reduction. Among them, the winding process parameters are optimized and set as follows: vehicle speed 1000m / min, winding tension 8cN, neps 200%, short thick places 110%×2cm, long thick places 33%×33cm, long details -33%×33cm .

[0025] b) Warping: GA124H batch warping machine is used to warp the blended yarn according to the process principle of medium speed, small tension and three uniformity. In order to prevent defects such as yarn falling, doubling and twisting on the pulp shaft, as well as unclear shedding and weaving defects during weaving, the warping process parameters are optimally set as follows: speed 500m / min, tension scale 3.3, winding density 0.55g / cm 3 , workshop temperature 25 ℃, relative humidity 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com