Paper pulp mixing device used for paper product producing and making

A mixing device and paper product technology, which is applied in the field of paper product processing, can solve the problems of low crushing efficiency and stirring efficiency, which cannot meet the efficiency requirements, and achieve the effects of easy maintenance, promotion and use, and easy crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

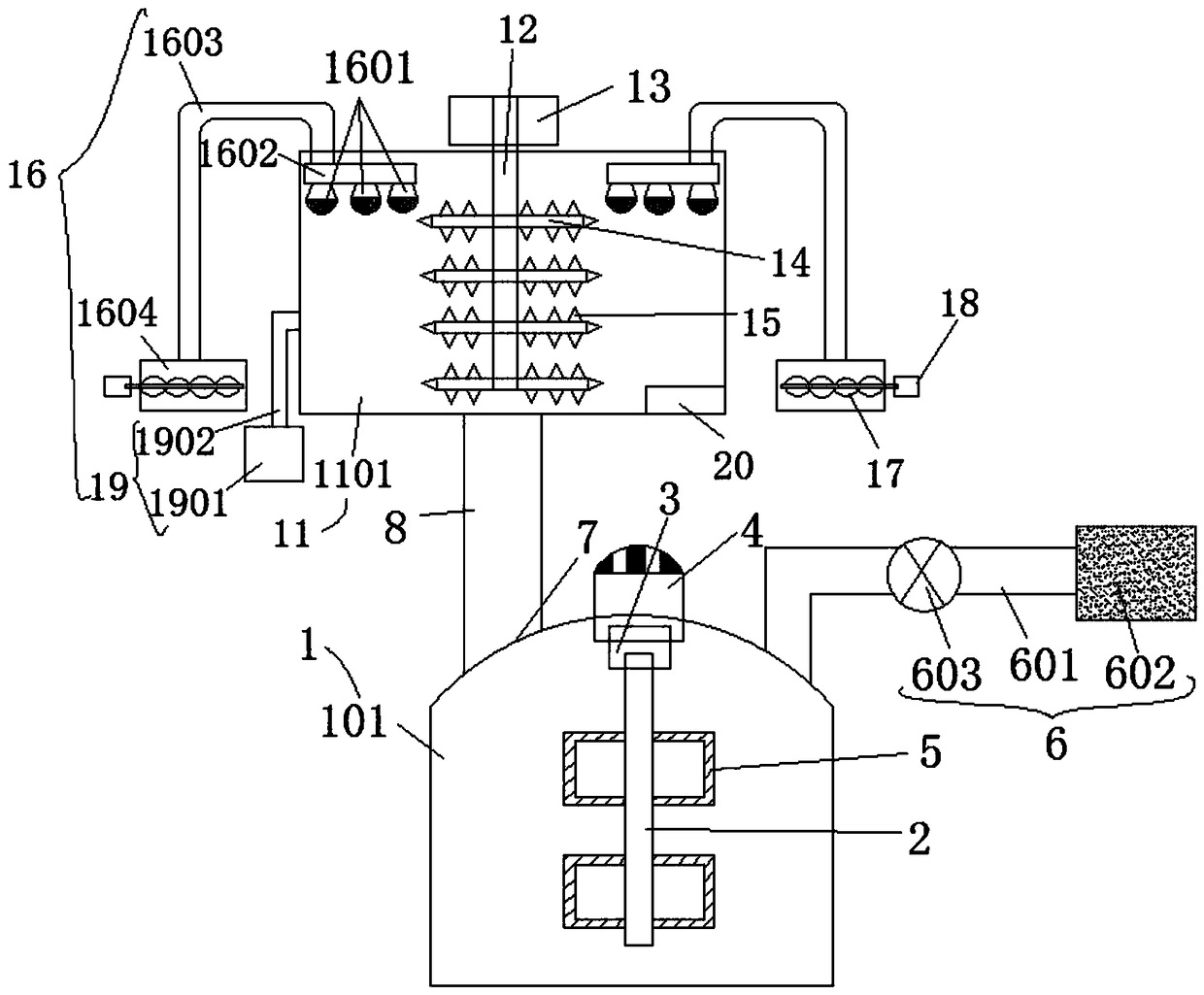

[0018] Example 1: see figure 1 and figure 2 Now, a pulp mixing device for the production and preparation of paper products provided by the present invention is described, including a stirring unit 1, the stirring unit 1 includes a stirring tank body 101, and a stirring shaft 2 is arranged inside the stirring tank body 101, The upper end of the stirring shaft 2 is connected to the stirring motor 4 through a coupling 3, the shaft body of the stirring shaft 3 is provided with a stirring paddle 5, and the right end of the stirring tank body 1 is connected with an additive delivery unit 6, the The additive delivery unit 6 includes a delivery pipeline 601 and a storage tank 602, the delivery pipeline 601 is provided with a control pump for controlling the input of the additive in the storage tank 602 into the reaction kettle body 101, and the upper end of the stirring tank body 101 A stock inlet 7 is provided, and the stirred tank body 101 is connected to the pulp inlet 9 of the p...

Embodiment 2

[0019] Example 2: see figure 1 , as an improvement of the present invention, the stirring paddle 5 is designed in a zigzag shape.

Embodiment 3

[0020] Embodiment 3: see figure 1 , as an improvement of the present invention, it also includes a freeze-drying unit 19 for freeze-drying paper products, and the freeze-drying unit 19 includes a liquid storage box 1901 for storing freeze-dried liquid, and the liquid storage box 1901 Located on both sides of the shredded paper box 1101 , the liquid storage tank 1901 is connected to the shredded paper box 1101 through the infusion pipeline 1902 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com