Indoor drilling simulation device in multi-factor environment and evaluation method

A simulation device and multi-factor technology, applied in the direction of earthwork drilling, measurement, borehole/well components, etc., can solve the problems of inability to simulate the force of rock formation, incapability of real reflection, inapplicability to deviated well sections, etc., and achieve test cost The effect of reducing and saving verification time and shortening R&D time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing, the present invention is described in further detail:

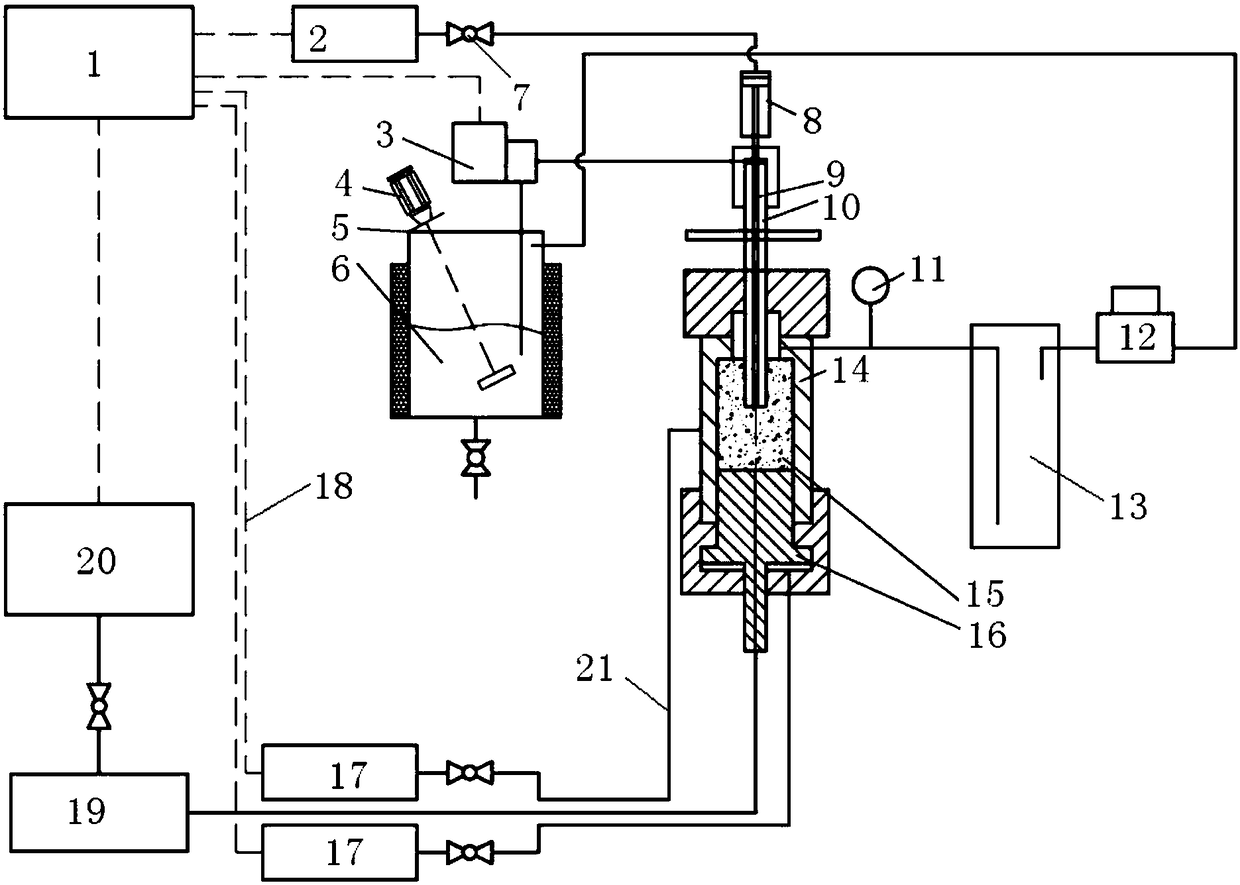

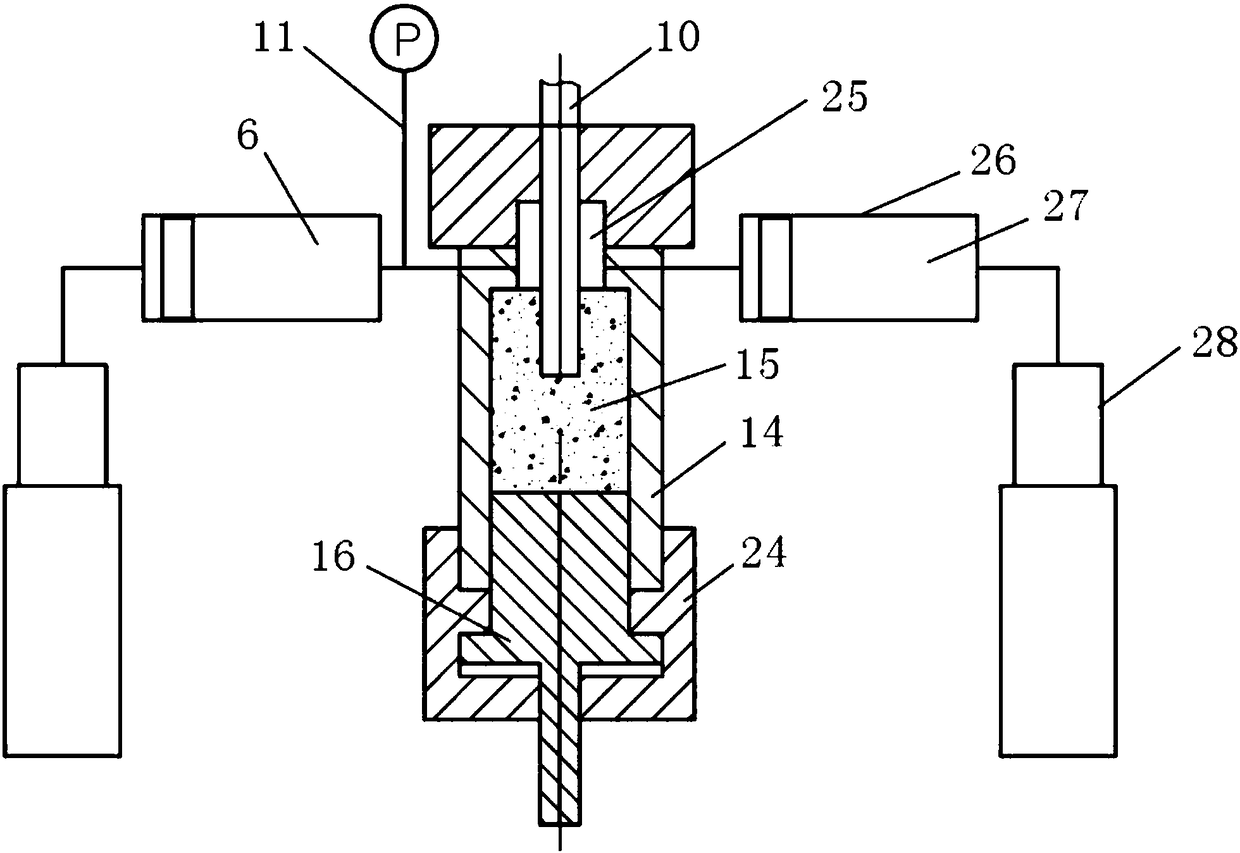

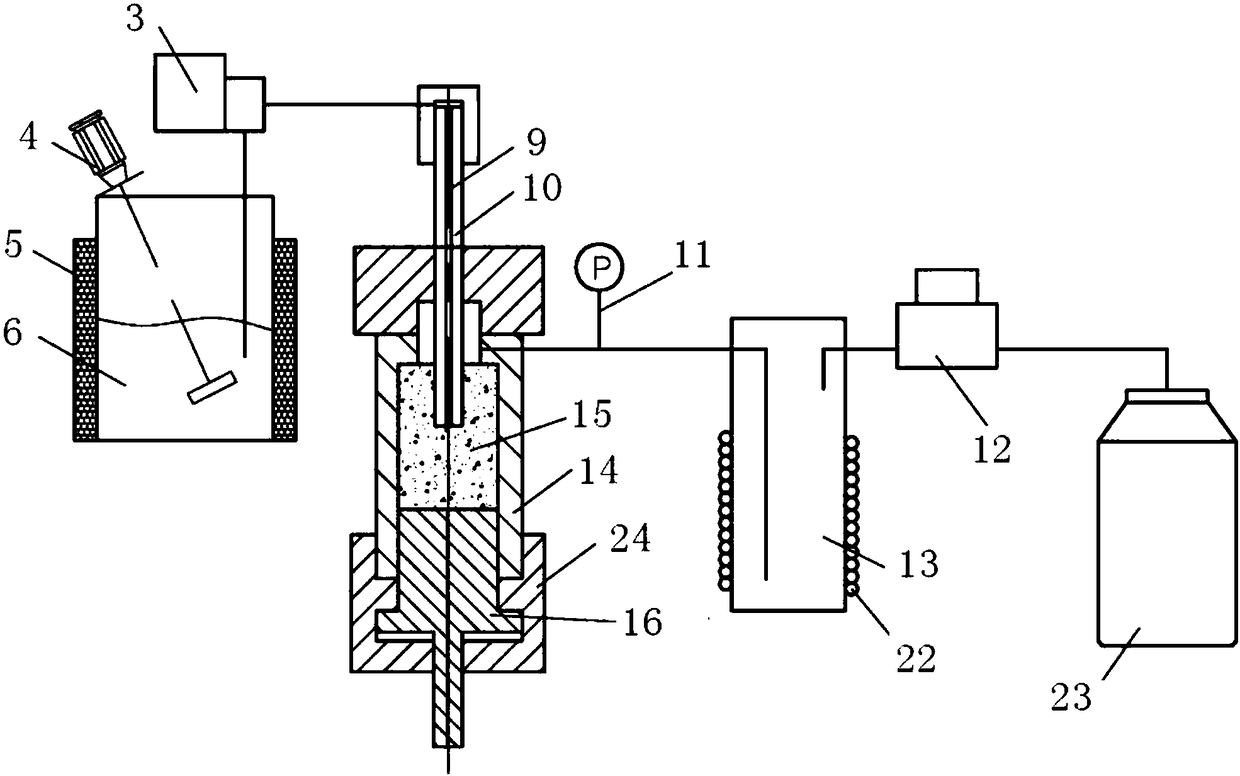

[0061] The invention can simulate the actual drilling process in the laboratory, and can conduct repeated drilling tests on the same rock sample under certain parameters such as temperature, pressure, and drill bit type, and test the impact of different drilling fluid treatment agents and system formulas on the drilling efficiency. and the influence law of bottom-hole cleaning effect. Such as figure 1 As shown, the device mainly includes the following parts: (1) core clamping system; (2) bottom hole circulation system; (3) overlying pressure system; (4) formation pressure system; (5) drilling pressure simulation system; 6) Rotary drive system; (7) Drilling depth measurement system; (8) Automatic control and data acquisition system 1.

[0062] The core clamping system is a sealing device for clamping cylindrical rock samples, which can apply confining pressure and ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com