Engine waste heat utilization system based on bionic uniform heating plate and pulsating heat pipe phase change heat storage technology

A phase change heat storage and pulsating heat pipe technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of heat loss in the cooling system and exhaust system, shortening engine life, difficult to start the engine, etc., so as to prolong the life. , the effect of reducing wear and speeding up the starting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

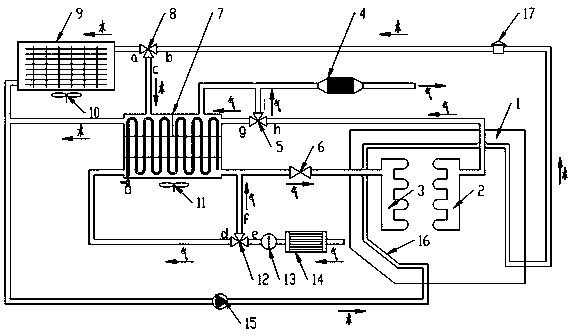

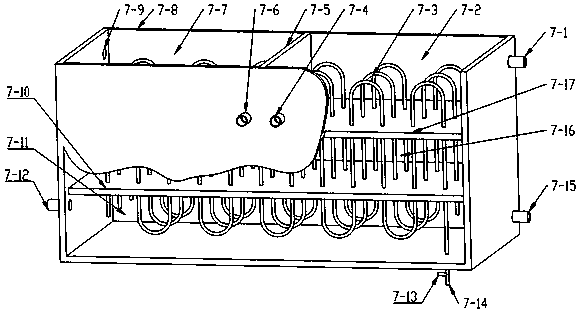

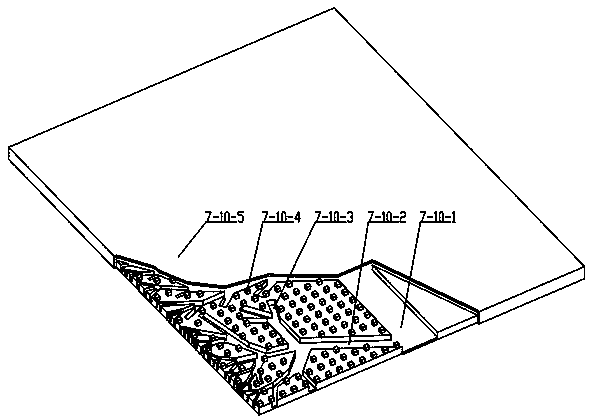

[0019] Such as figure 1 As shown, the engine waste heat utilization system based on bionic vapor chamber and pulsating heat pipe phase change heat storage technology is characterized in that it is composed of engine 1, cooling system, air intake system and exhaust system; the cooling system is composed of engine block cooling water jacket 16. Temperature sensor 17, water pump 15, fan I 10, fan II 11, radiator 9, pulsating heat pipe phase change accumulator 7, cooling system three-way valve 8, air intake system consists of air filter 14, air flow meter 13 , intake manifold 3, intake system three-way valve 12, intake valve 6 and cylinder; exhaust system consists of exhaust manifold 2, exhaust hose, catalytic converter 4 and exhaust system three-way valve 5 composition.

[0020]In a cold environment, hot water flows out from the cylinder cooling water jacket 16 during the operation of the engine 1, and the temperature sensor 17 monitors the water temperature. The three-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com