Centrifugal pump self-absorbing device used for easily-crystallized medium

The technology of self-priming device and centrifugal pump is applied to the parts of pumping device for elastic fluid, pump of special fluid, pump and other directions, which can solve the problems of easy damage of electronic control element, complicated structure and difficulty in filling tank, etc. Achieve the effect of preventing premature damage, simple control method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

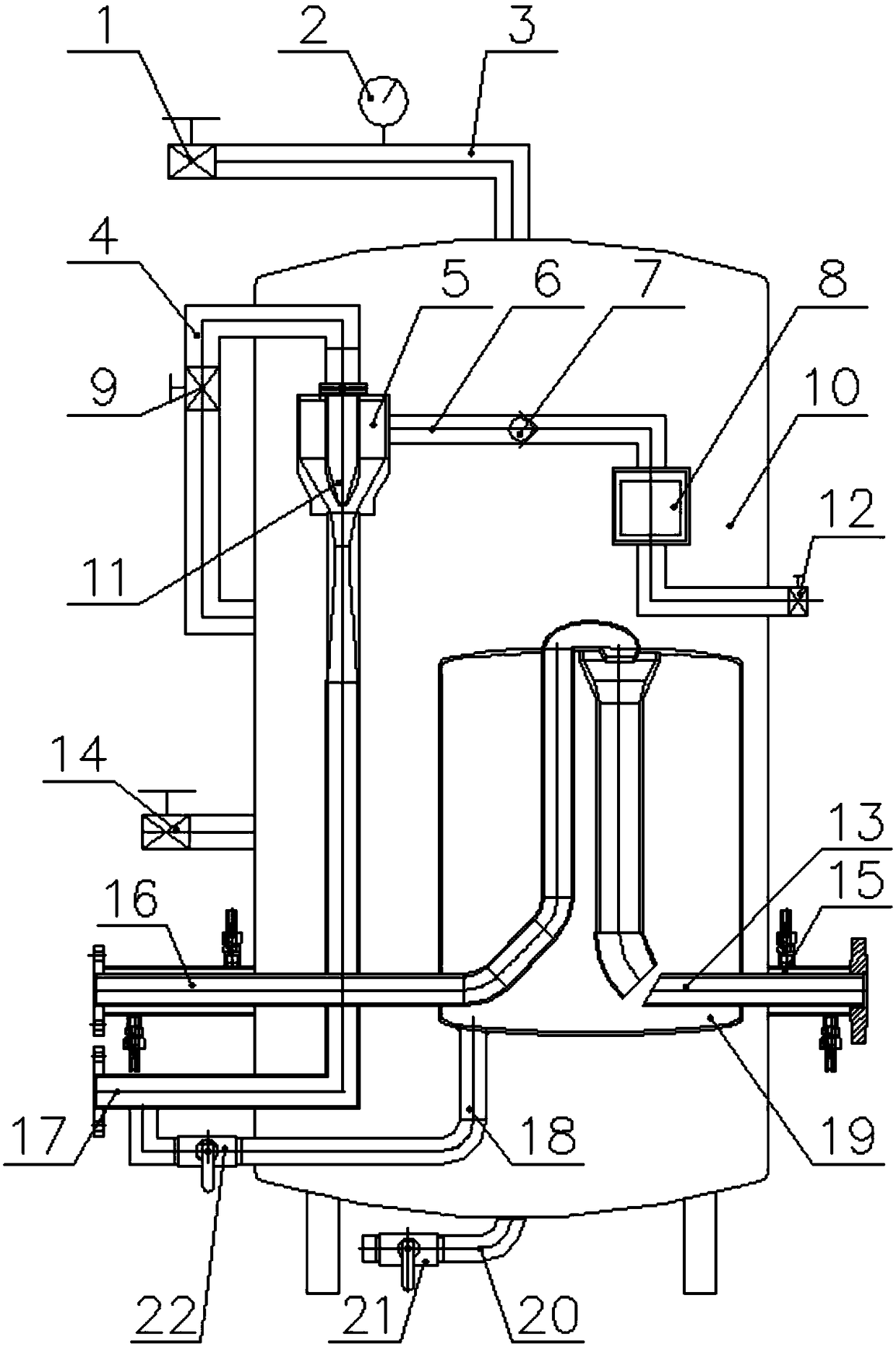

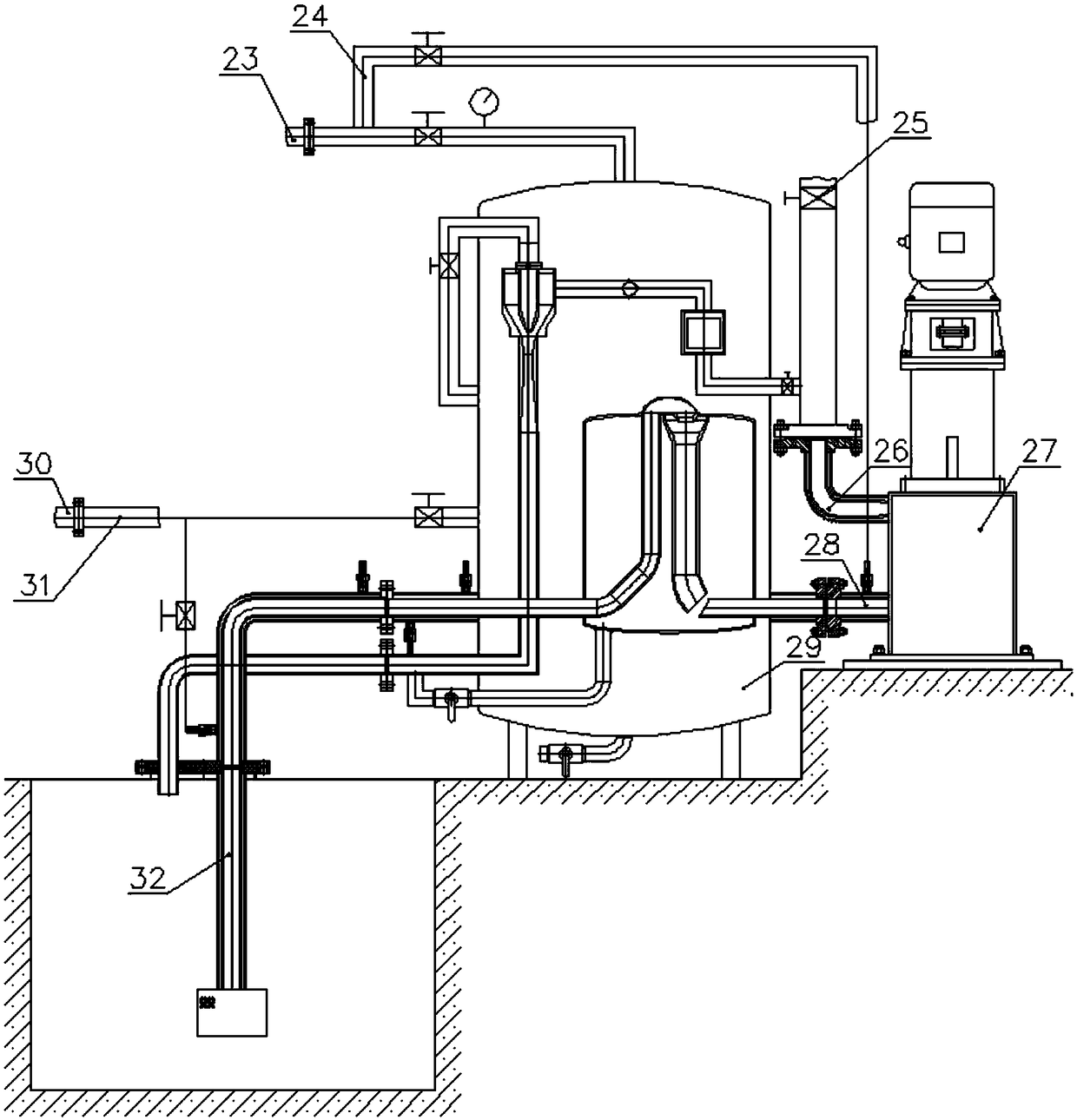

[0038] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 2 As shown, the present invention provides a centrifugal pump self-suction device 29 for easily crystallized medium, which includes a surge tank 10 , an ejector 5 and a jet tank 19 . This embodiment is suitable for working conditions where the whole device needs to be started frequently during operation.

[0039] The surge tank 10 is used to store the gas source and heat the components installed inside it. The top of the surge tank 10 is provided with a surge tank inlet pipe 3, and the bottom of the surge tank 10 is provided with a surge tank steam outlet pipe 31. The tank steam outlet pipe 31 is provided with a surge tank steam outlet valve 14, and the bottom of the surge tank 10 is provided with a surge tank drain pipe 20, and the surge tank drain pipe 20 is provided with a surge tank drain pipe valve 21, and The tank inlet pipe 3 communicates with the steam line inlet pip...

Embodiment 2

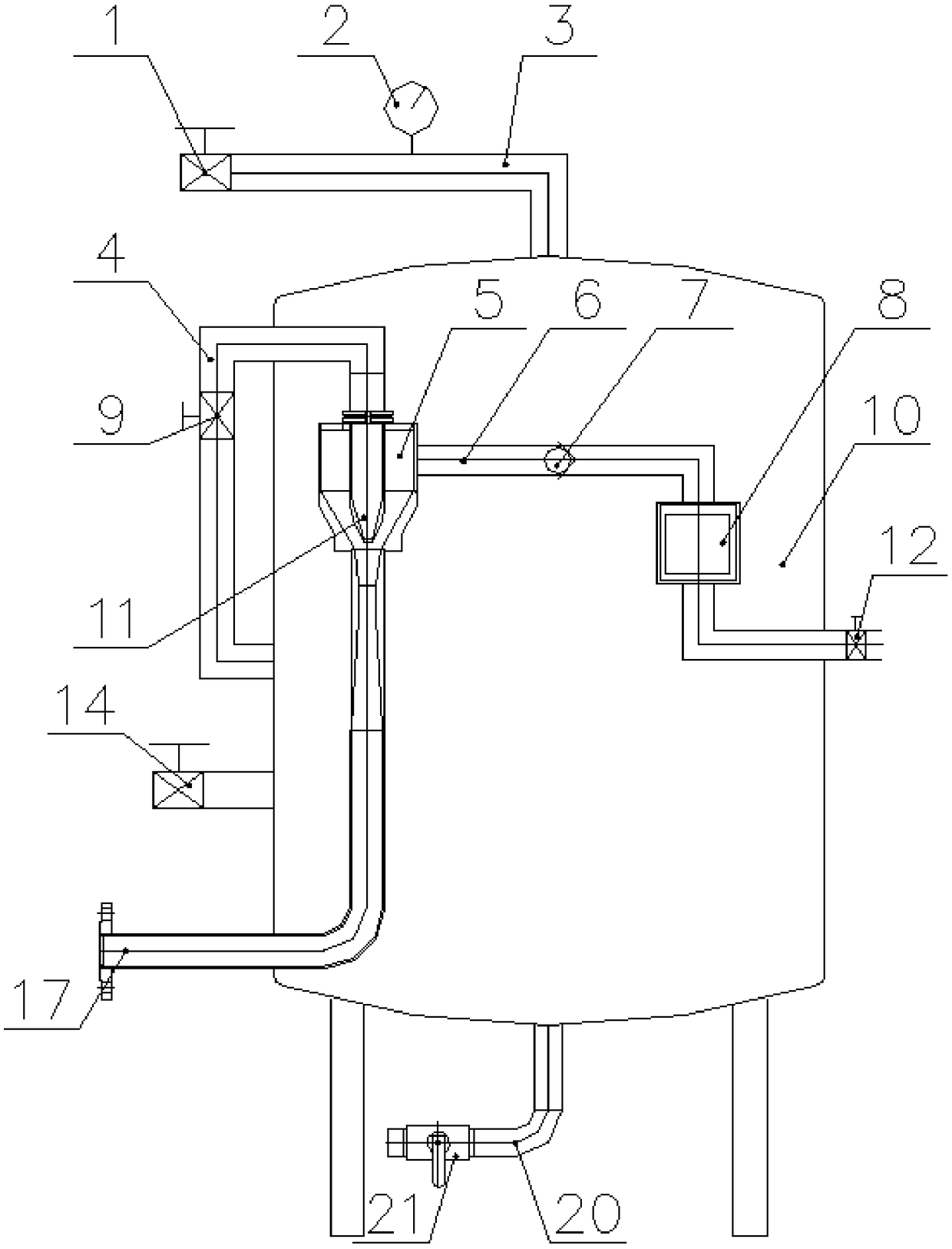

[0055] In order to solve the problems existing in the existing technology, such as Figure 3 to Figure 4 As shown, the present invention provides a centrifugal pump self-priming device 29 for crystallization-prone media, and the centrifugal pump self-priming device 29 for crystallization-prone media includes a surge tank 10 and an ejector 5 . This embodiment is applicable to the working condition that the centrifugal pump adopts the backflow mode when there is no need to stop the pump or other equipment is not working except for overhaul, and still maintains low-level operation.

[0056] The surge tank 10 is used to store the gas source and heat the components installed inside it. The top of the surge tank 10 is provided with a surge tank inlet pipe 3, and the bottom of the surge tank 10 is provided with a surge tank steam outlet pipe 31. The tank steam outlet pipe 31 is provided with a surge tank steam outlet valve 14, and the bottom of the surge tank 10 is provided with a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com