Nozzle structure suitable for pulsation combustor vibration combustion and design method

A technology of pulsating combustion and oscillating combustion, which is applied in the direction of combustion methods, burners, gas fuel burners, etc., can solve the problems that the burner cannot work normally and stably, and achieve the goal of reducing manpower and material resources, development cycle, simple structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0041] In this embodiment, the nozzle structure design method of the present invention is used for the nozzle design of the pulse burner in the oil field, and the implementation process of the method is described in detail. The effectiveness of the invention is verified by comparing the experimental results of nozzles with different structures.

[0042] Below in conjunction with accompanying drawing, the present invention will be further described:

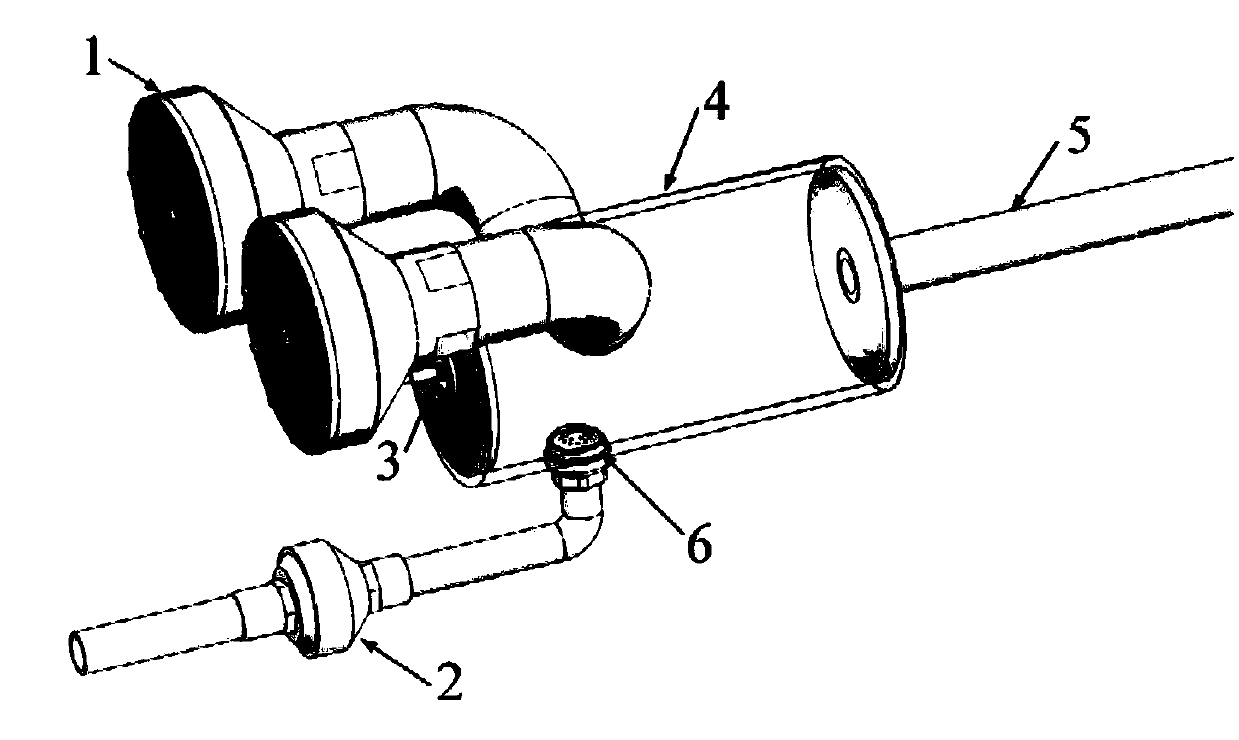

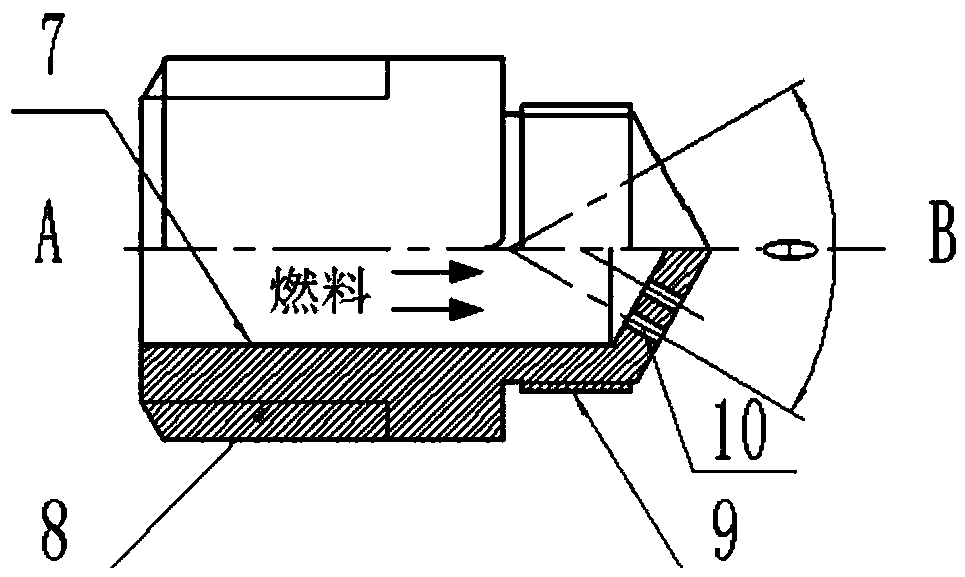

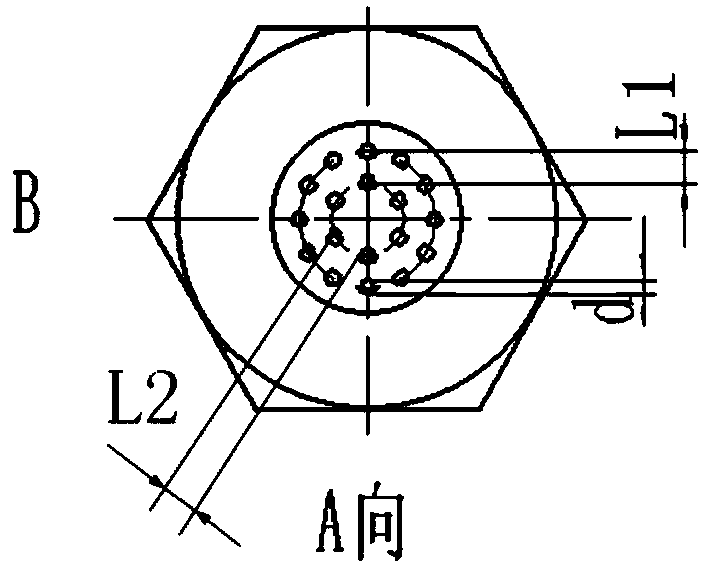

[0043] Such as figure 1 Shown is a schematic diagram of the arrangement and installation of the pulsation burner nozzle. An oilfield pulsation burner is used for heating crude oil or natural gas for export, and the fuel is oilfield associated gas. The pulse burner is composed of two air chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com