Boil-off gas treatment system and ship

A technology for evaporating gas and processing systems, which is applied in the direction of fluid processing, gas processing/storage purposes, gas processing/storage effects, etc., and can solve problems such as incombustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

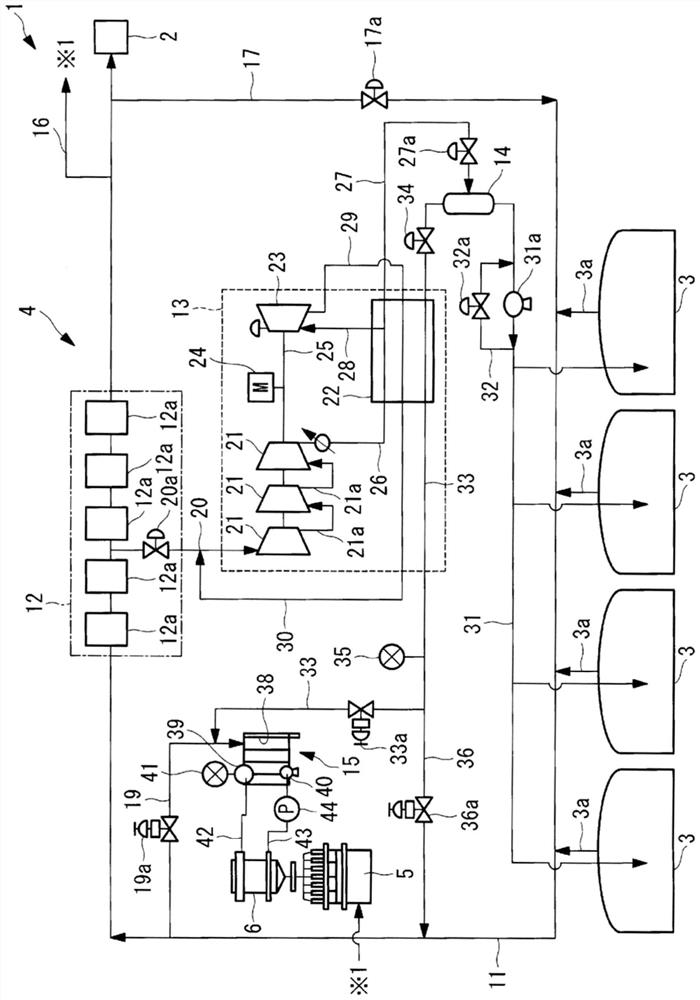

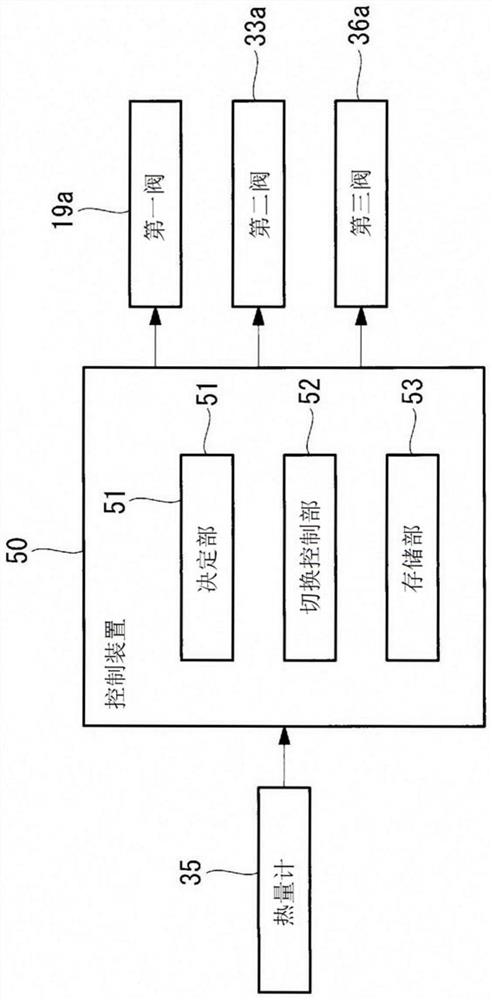

[0034] Hereinafter, an embodiment of the boil-off gas processing system and the ship according to the present invention will be described with reference to the drawings.

[0035] The boil-off gas treatment system 4 according to this embodiment is suitable for the ship 1 that transports LNG (liquefied natural gas, Liquefied Natural Gas). In addition, the objects transported by the ship 1 are not limited to LNG, for example, other liquefied gases such as LPG (Liquefied Petroleum Gas) may also be used.

[0036] The ship 1 is equipped with: an engine for the main engine (internal combustion engine for the main engine) 2, a tank 3 for storing LNG (liquefied gas), a boil-off gas treatment system 4 for processing the boil-off gas generated in the tank 3, and a power generator for generating electricity for use in the ship. A diesel engine 5, and an economizer 6 for generating steam by utilizing the heat of exhaust gas discharged from the diesel engine 5 for power generation.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com