Rubber component for fire-lighting device

An ignition device and component technology, which is applied in the direction of combustion ignition, igniter with fuel, transportation and packaging, etc., can solve the problems of hindering gas supply, unstable gas supply flow, and ignition device cannot pre-mix air, etc., to achieve Guaranteed burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now, referring to the drawings, an embodiment of the present invention will be described in detail.

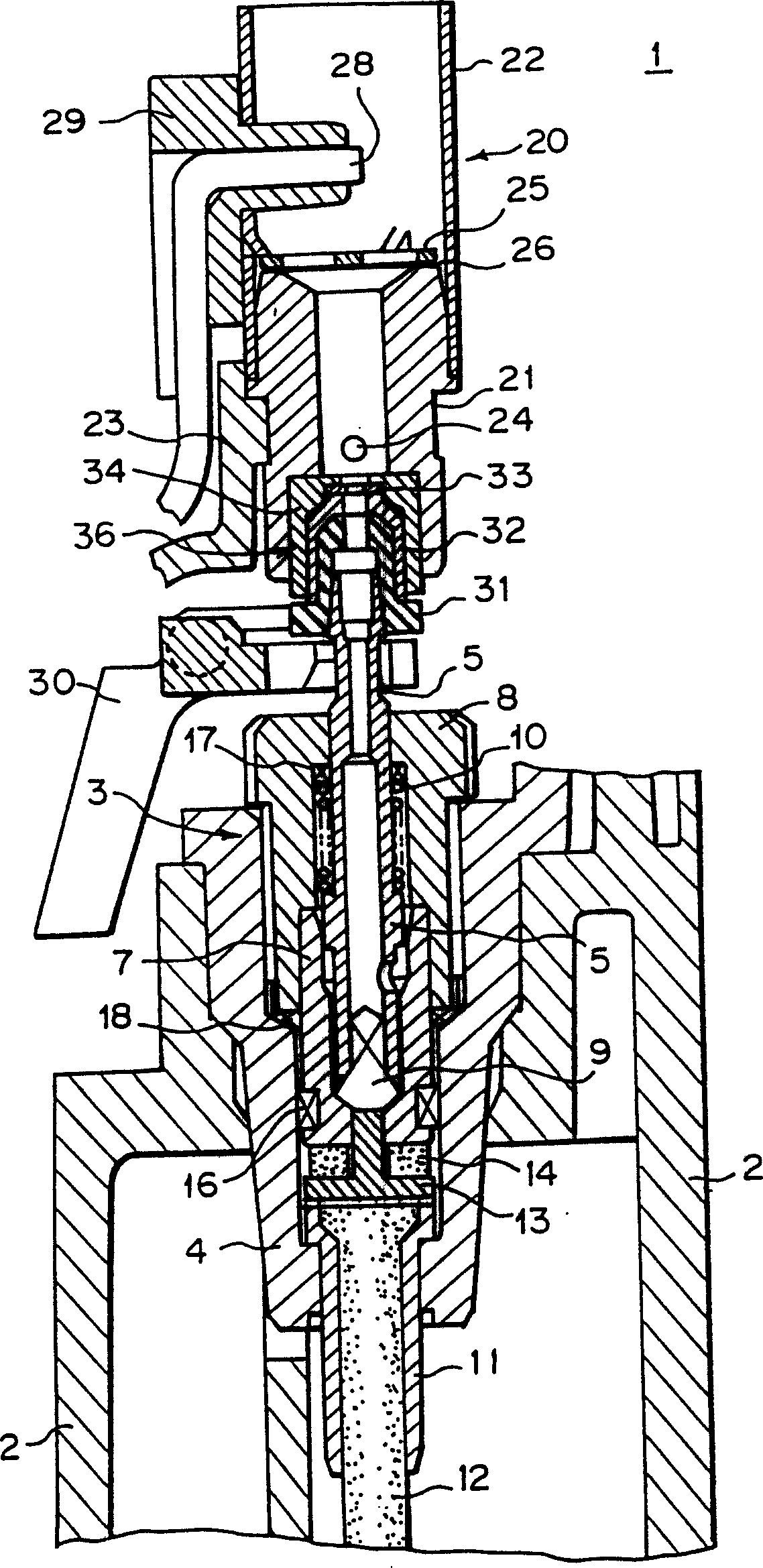

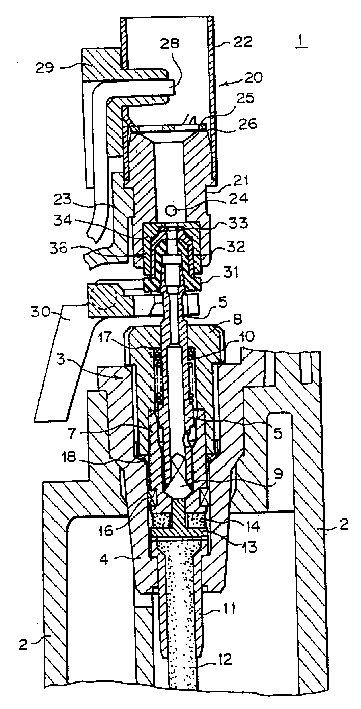

[0015] figure 1 It is a cross-sectional structural view of a main part of a gas fuel cigarette lighter as an example of an ignition device using a rubber member according to the present invention.

[0016] This gas fuel cigarette lighter is represented by code number 1, is a kind of traditional structure. At its lower part, there is a main tank body 2 for storing fuel gas, which is made of synthetic resin for storing high-pressure fuel gas such as butane gas. The fuel supply device 3 includes a connection nozzle 5 for injecting fuel gas, installed on the top of the main storage tank body 2 and placed in the valve chamber 4 . A burner 21 defined by a combustion tube 22 and a combustion cylinder 20 are installed above the connection nozzle 5 for burning the fuel gas injected from the connection nozzle 5 . As its gaseous combustion system, the combustion cylinder 20 use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com