Resonant-type double-shaft micro mechanical wheel-type gyro

A micro-mechanical and resonant technology, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, instruments, etc., can solve the problems of high process compatibility requirements, device performance impact, large volume, etc., and achieve the process Simplicity, productivity improvement, and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

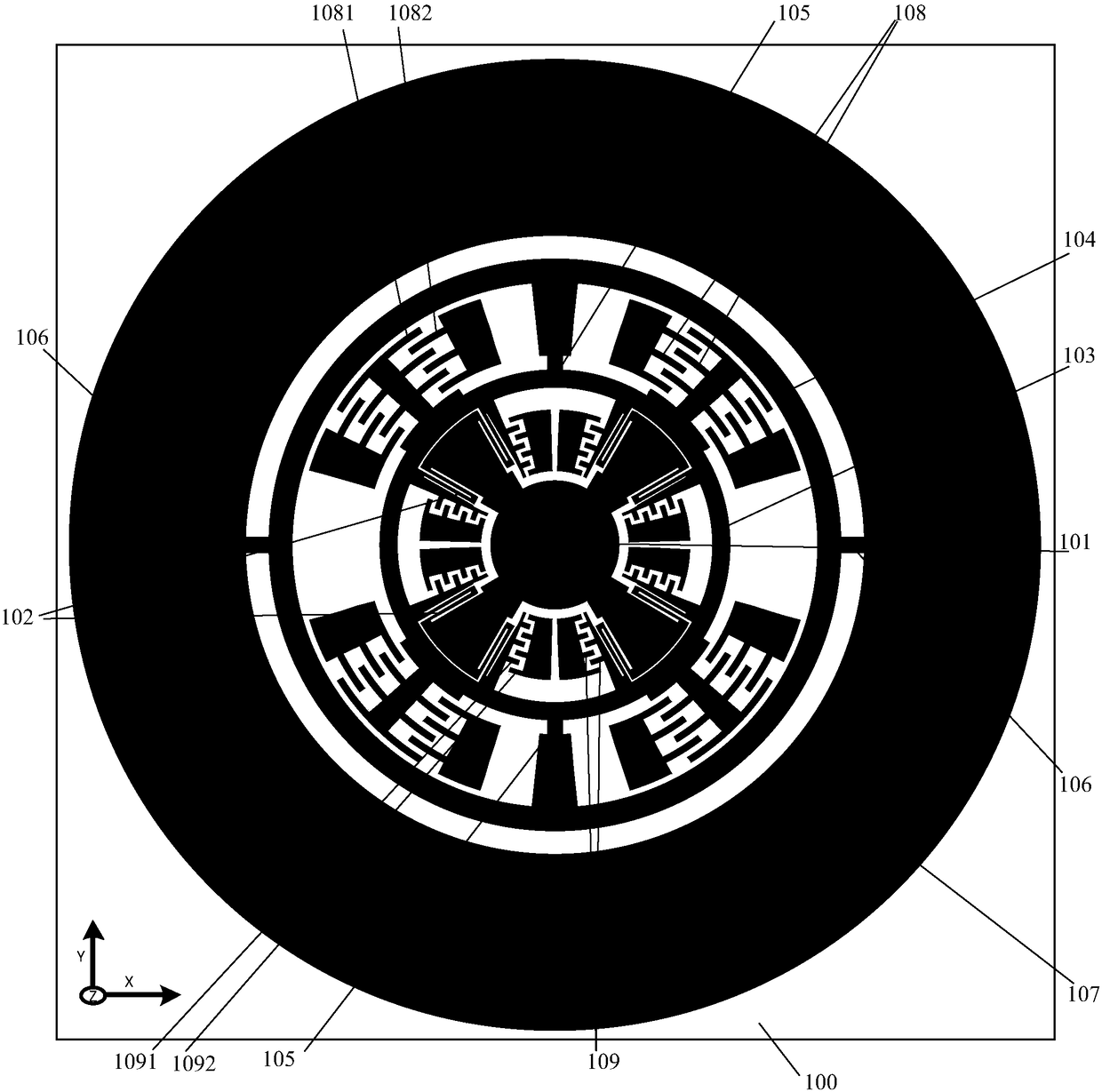

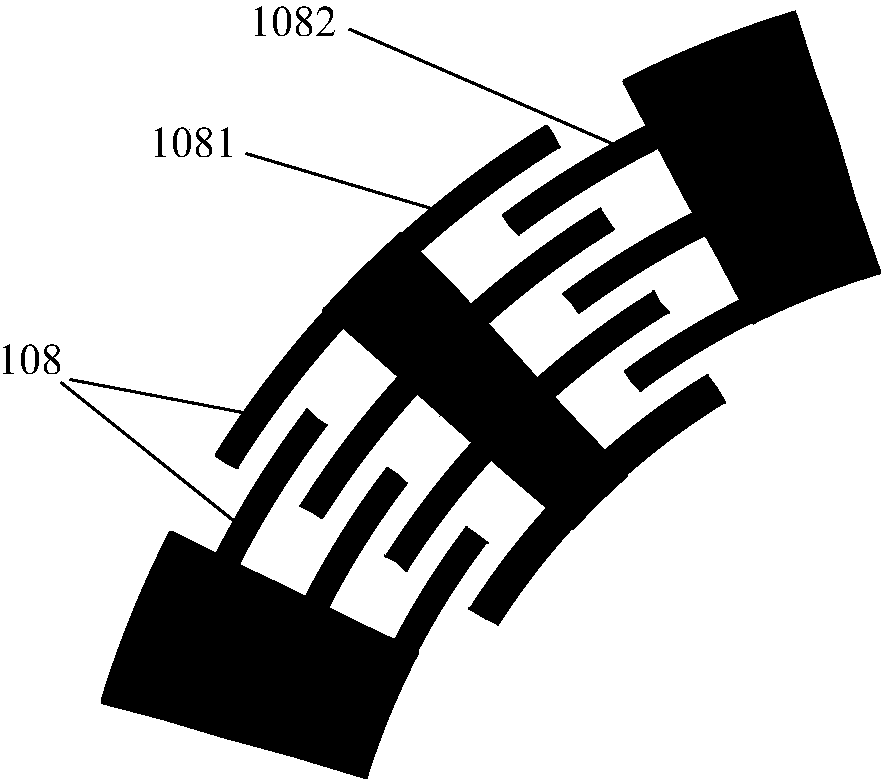

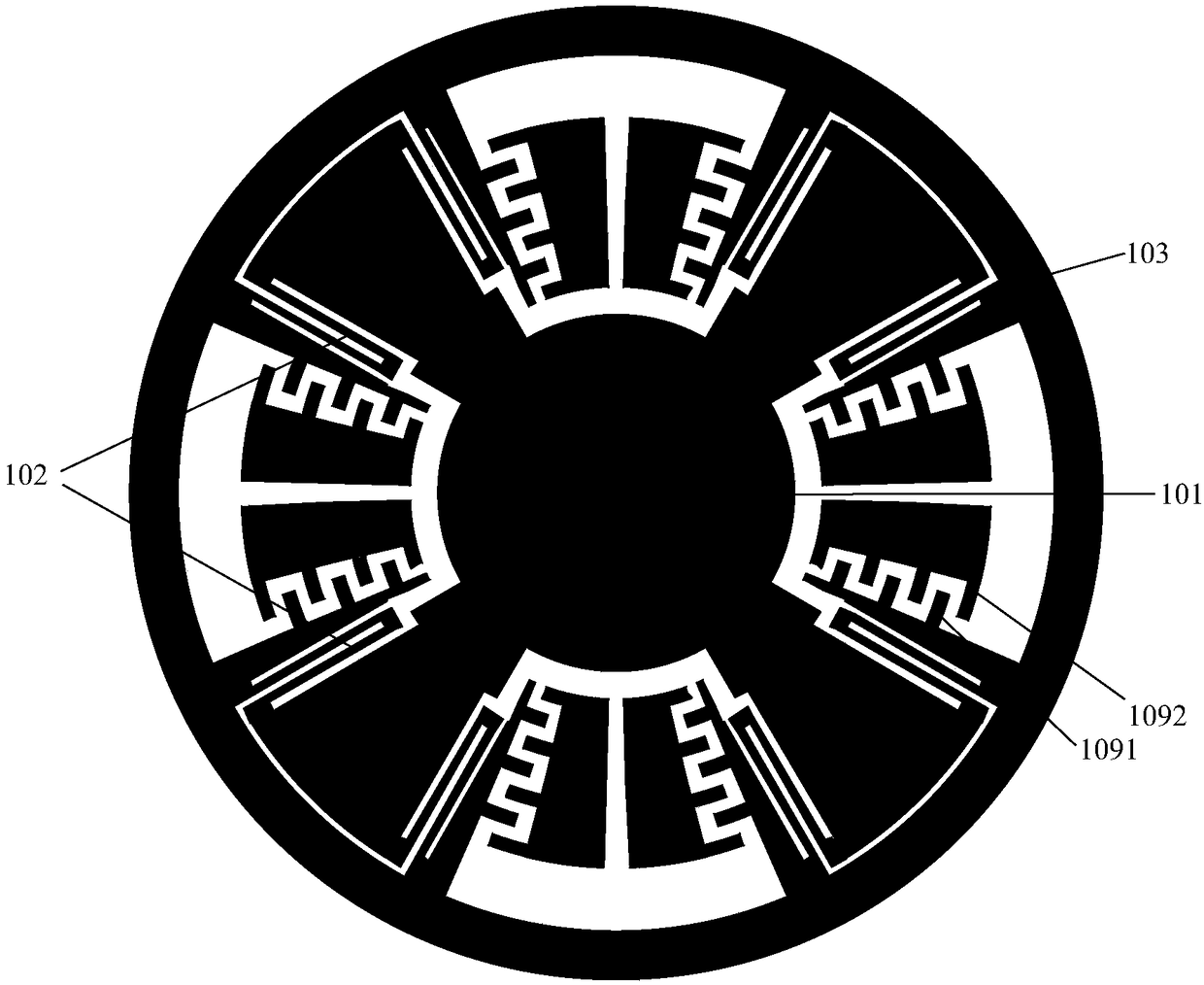

[0025] like figure 1 As shown, the present invention is a resonant dual-axis micromechanical wheeled gyroscope, which includes a substrate 100, a central axis 101, a driving folded beam 102, an inner ring frame 103, an outer ring frame 104, and a detection X-axis torsion beam 105, Detect the Y-axis torsion beam 106 , detect the mass block 107 , drive the comb-tooth capacitor 108 , and drive the feedback comb-tooth capacitor 109 .

[0026] Among them, the anchor point 101 drives the folded beam 102, the inner ring frame 103, the outer ring frame 104, the proof mass 107, the drive comb capacitor 108, and the drive feedback comb capacitor 109 are symmetrically distributed with respect to the X and Y axes of the gyroscope, and the detection of the X axis The torsion beams are distributed symmetrically wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com