High-transmittance atomic beam microscopic apparatus

A high-transmittance, atomic-beam technology, applied in measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of insufficient focusing of atomic beams, limited atomic transmittance, and difficult processing, etc., to achieve Sharp focus beam spot, suppress diffraction, optimize focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

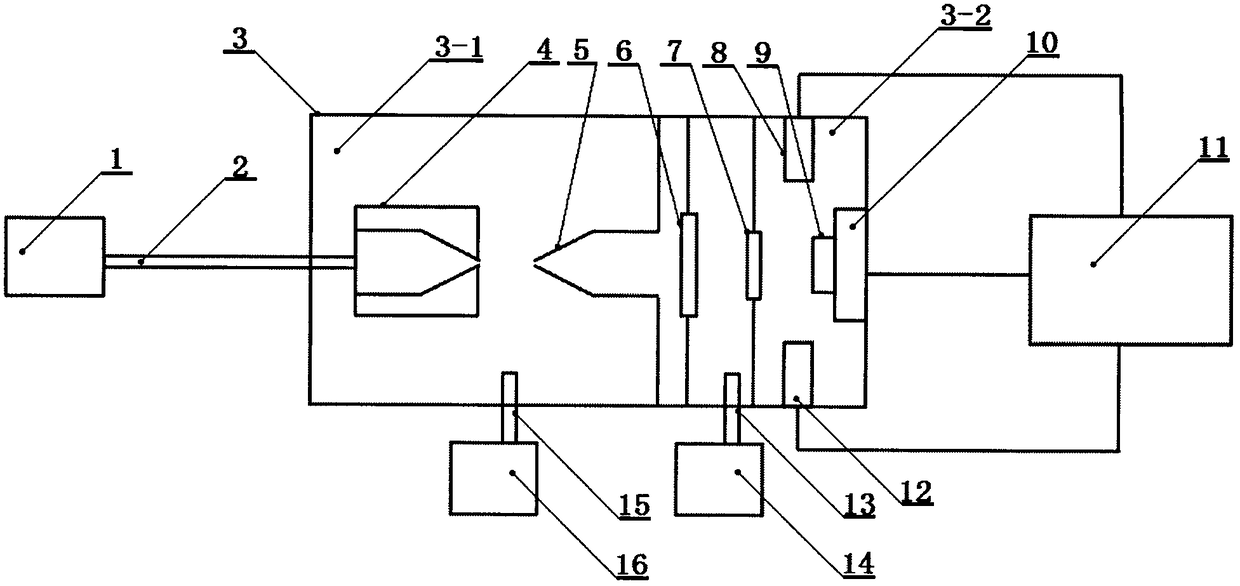

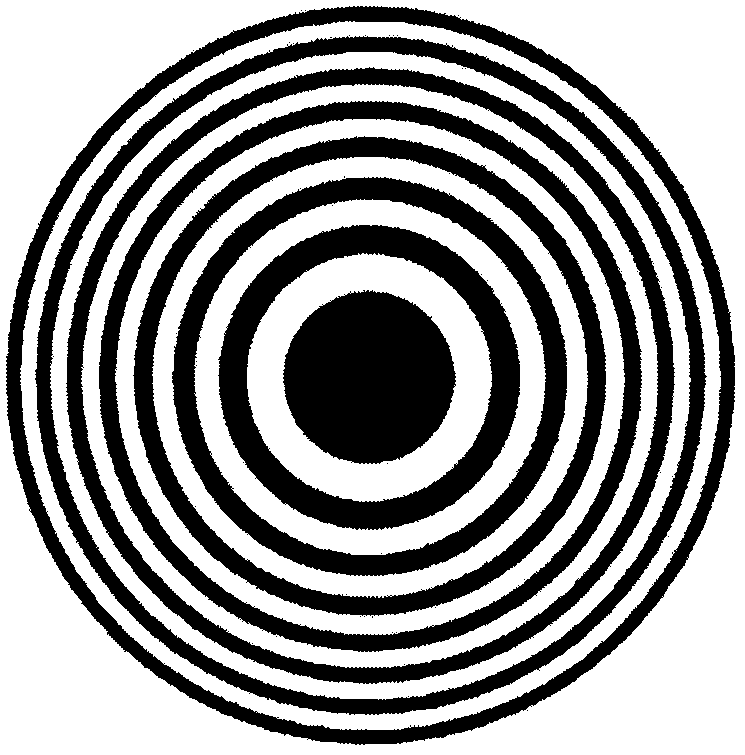

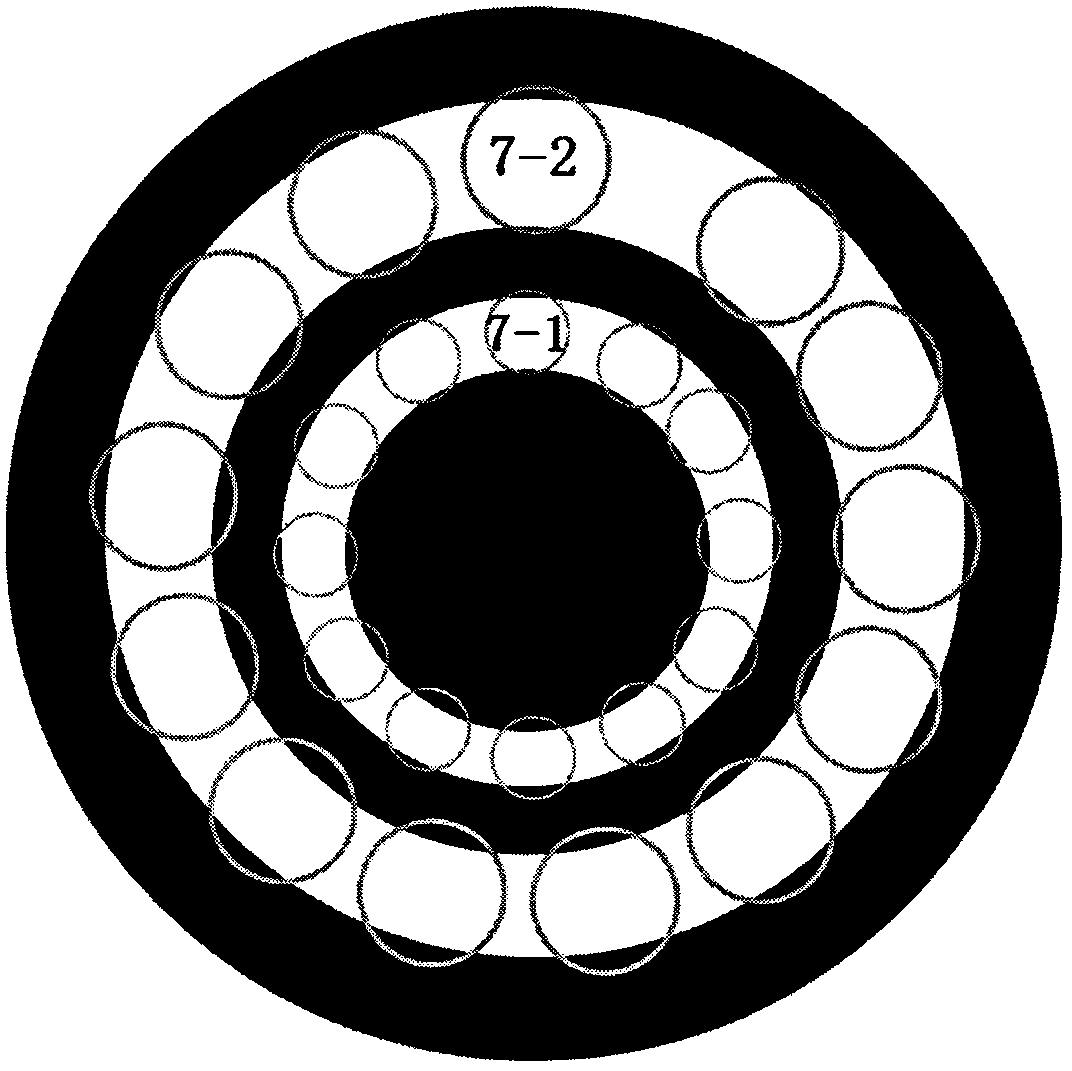

[0026] Such as figure 1It is a schematic diagram of the present invention, mainly comprising a gas storage tank (1), a gas pipe (2), a vacuum chamber (3) connected by a chamber body I (3-1) and a chamber body II (3-2), and a spray head ( 4), splitter (5), gas transmission window (6), atomic diffraction sheet (7), through hole (7-1) on the transmission area of the first-order Fresnel ring zone, second-order Fresnel Through hole (7-2) on the transmission area of the annular zone, detector I (8), sample (9), sample stage (10), computer (11), detector II (12), gas extraction port I (13) , vacuum pump group I (14), air inlet II (15), vacuum pump group II (16), the cavity I (3-1) and cavity II (3-2) are connected by a flow divider (5), and the cavity The body II (3-2) is connected to the vacuum pump group I (14) through the suction port I (13), the cavity I (3-1) is connected to the vacuum pump group II (16) through the suction port II (15), and the detector I (8 ) is the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com