Pressure container cooling system based on vacuum chamber

A pressure vessel and cooling system technology, applied in cooling devices, greenhouse gas reduction, reactors, etc., can solve the problems of poor cooling effect of the cooling system, achieve energy saving, high utilization rate, and avoid failure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

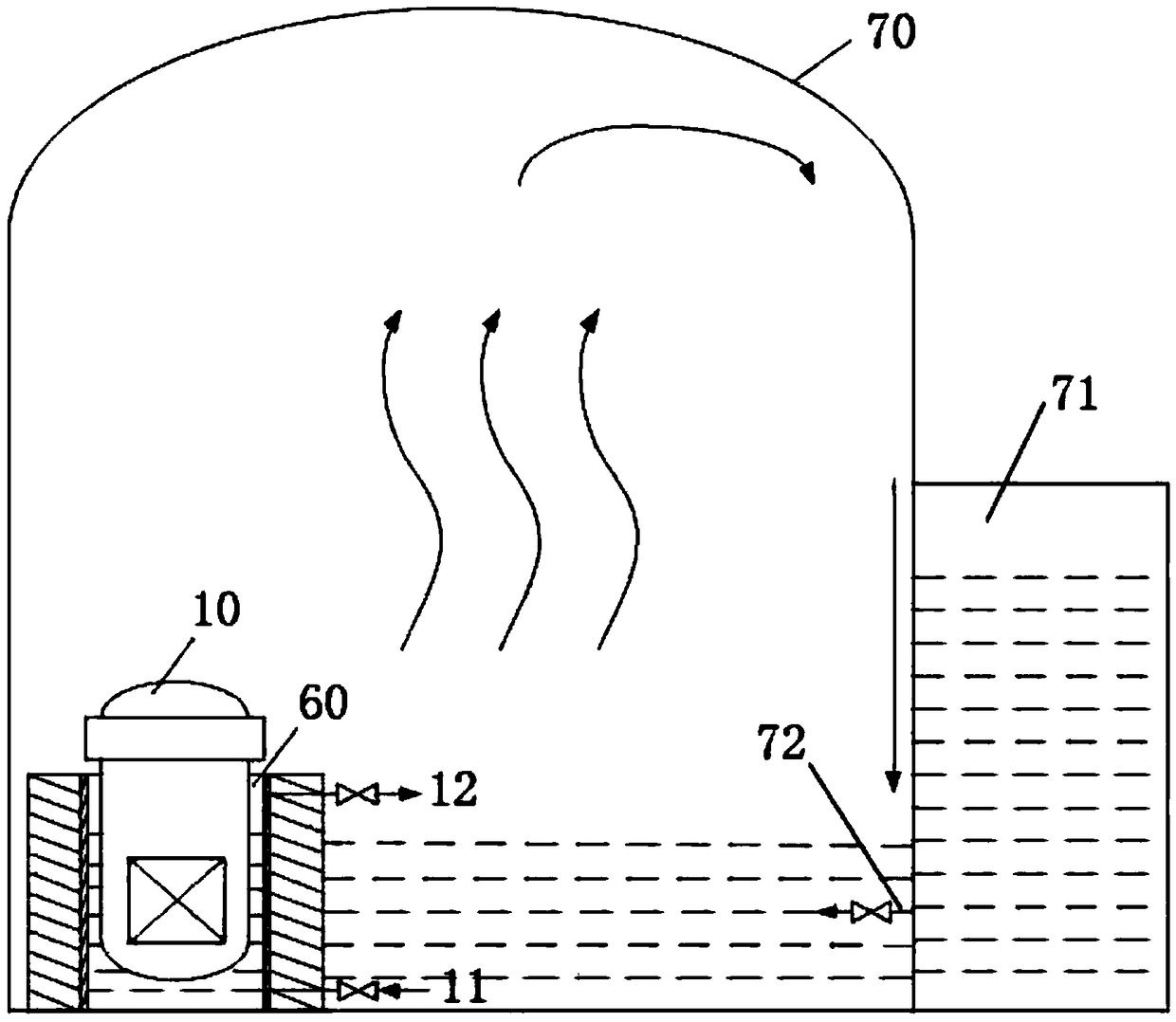

[0019] The invention provides a pressure vessel cooling system based on a vacuum chamber, which ensures the heat preservation effect of the pressure vessel under normal operating conditions and realizes external cooling of the wall surface of the pressure vessel after a serious accident occurs. The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

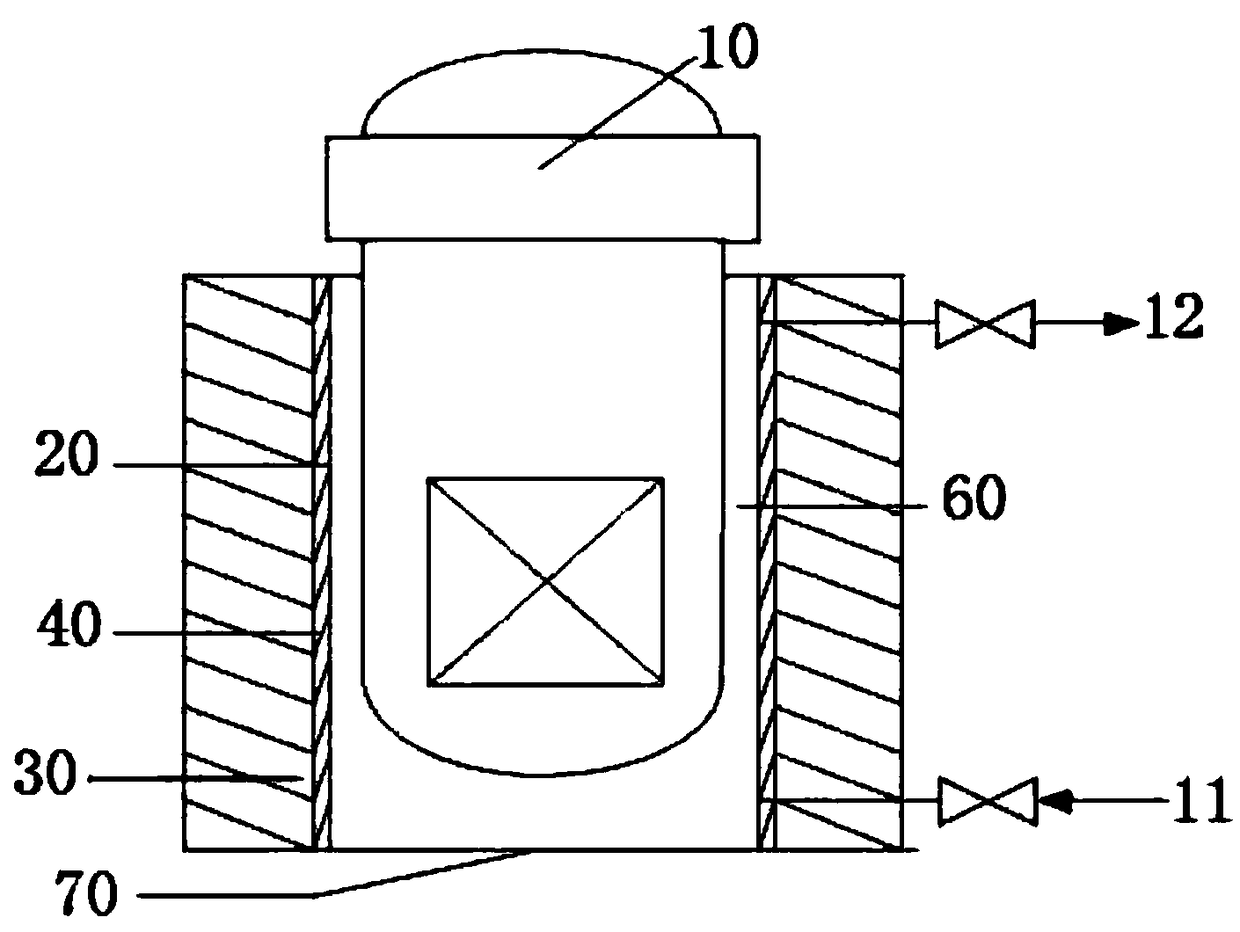

[0020] Such as figure 1 As shown, a vacuum chamber-based pressure vessel cooling system provided by the present invention includes a stainless steel outer cylinder 20 , a shielding layer 30 and a steel containment vessel 70 . The stainless steel outer cylinder 20 is disposed on the outer periphery of the pressure vessel 10 and forms a vacuum chamber 60 with the pressure vessel 10 . The shielding layer 30 is arranged on the periphery of the stainless steel outer cylinder 20, and the water inlet pipe 11 and the water outlet pipe 12 respectively pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com