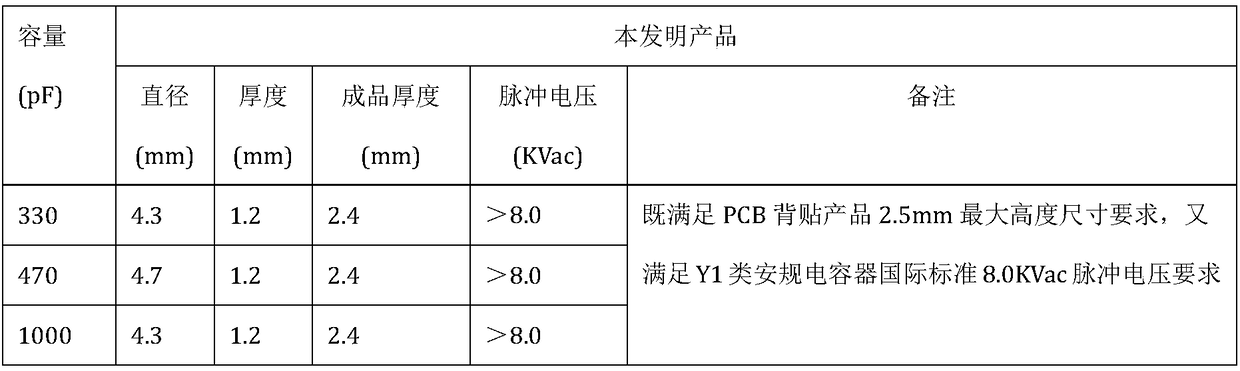

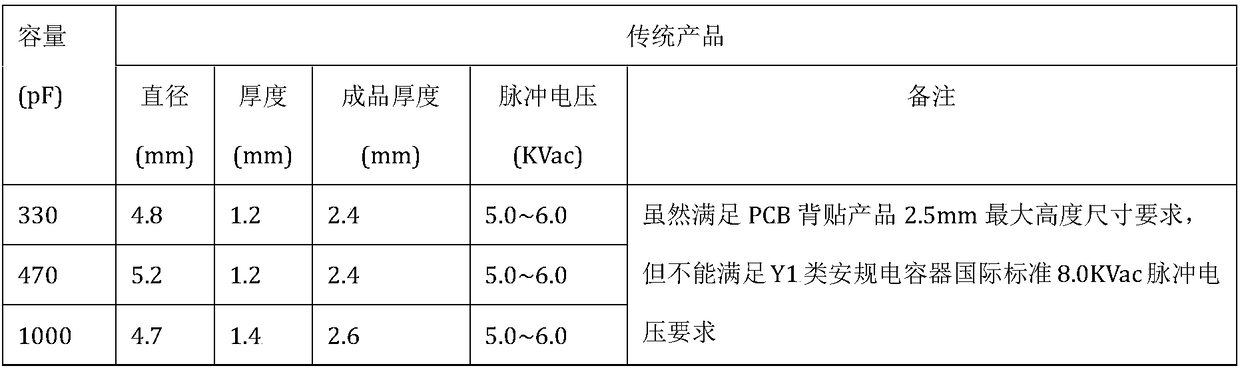

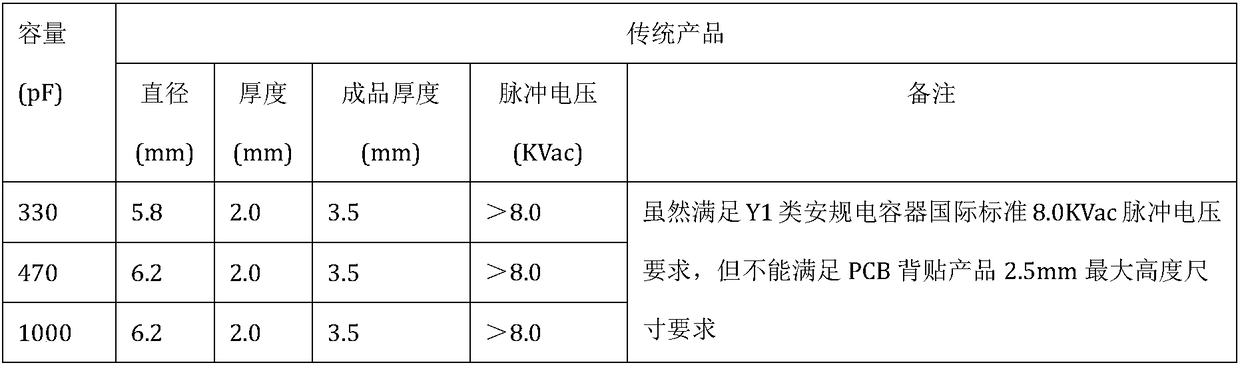

Miniaturized high-reliability patch type safety ceramic capacitor and processing method thereof

A processing method and reliable technology, applied in capacitors, capacitor manufacturing, fixed capacitor dielectrics, etc., can solve the problems of porcelain body damage, incomplete electrode symmetry, large volume, etc., to achieve low dielectric loss, high dielectric constant, high The effect of electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The production process is as follows:

[0032] 1. Will be made of BaTiO 3 , SrTiO 3 、 Bi 2 o 3 , Nb 2 o 5 , ZnO, MnO 2 After the raw materials are mixed evenly in a certain proportion, they are ground by a sand mill until the fine ceramic powder with particle size D50 below 1.0 μm and D90 below 1.5 μm is sprayed or centrifugally granulated to form a high-performance ceramic powder, of which SL The dielectric constant of characteristic ceramic powder is 300-330, the dielectric loss is less than 0.1%, and the dielectric strength is more than 12KVAC / mm. The dielectric constant of B-characteristic ceramic powder is 3500-4000, and the dielectric loss is less than 2.5%. / mm, the dielectric constant of the E characteristic ceramic powder is 9300-10000, the dielectric loss is less than 1.0%, and the dielectric strength is more than 8KVAC / mm.

[0033] 2. Press the green sheet after 1 safety capacitor ceramic powder is pressed to raise the temperature to 1200°C-1400°C at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com