Through-hole single-side direct-connection solar cell module and preparation method

A technology for solar cells and solar cells, applied in the field of solar cells, can solve the problems of occupying the light-receiving area of components, wire loss of metal welding strips, and easy rupture and corrosion of welding strips, so as to achieve small gaps between cells and reduce line losses. , the effect of reducing equipment costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0069] Specifically, the electrodes of the first solar cell shown have various implementations, including:

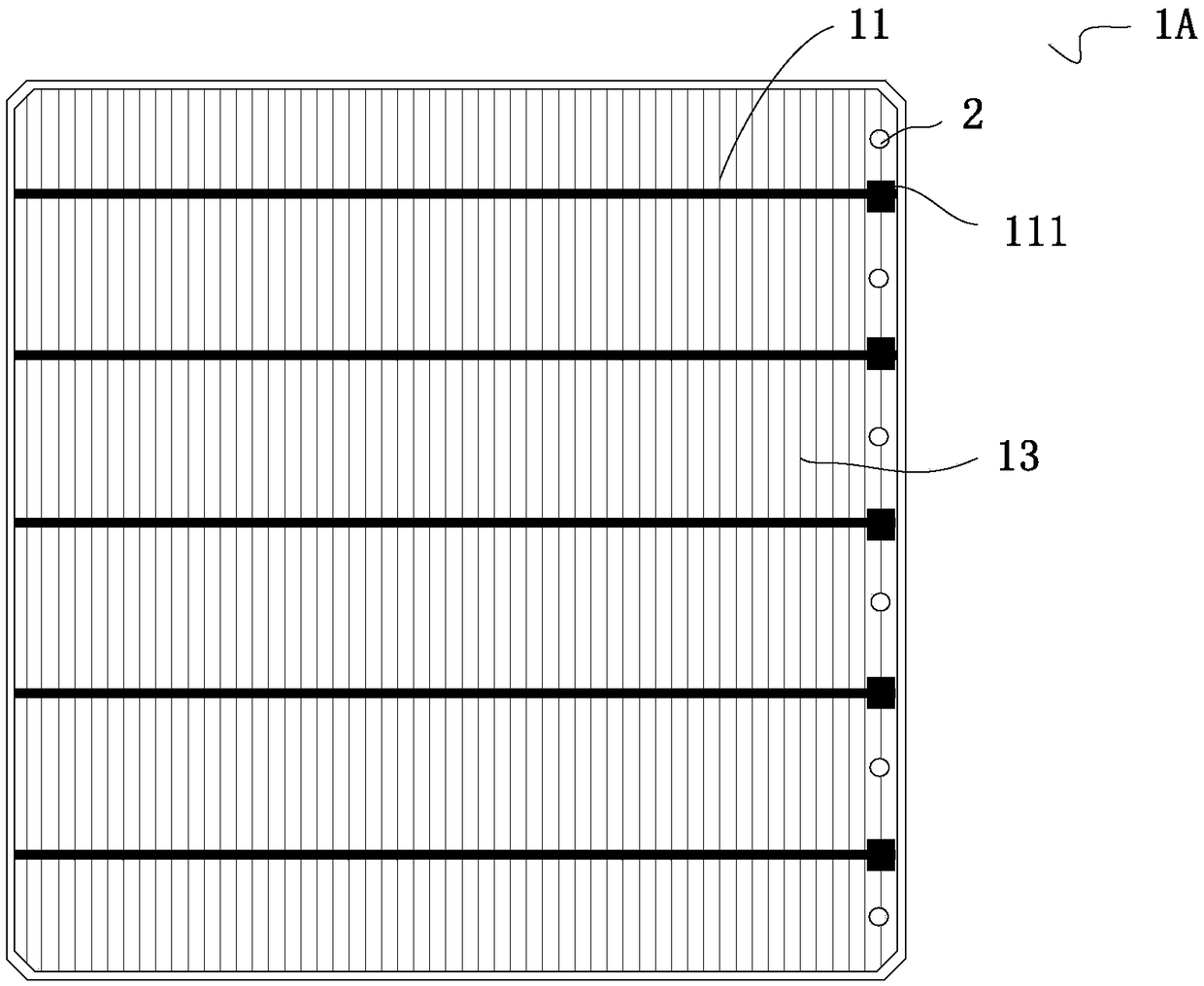

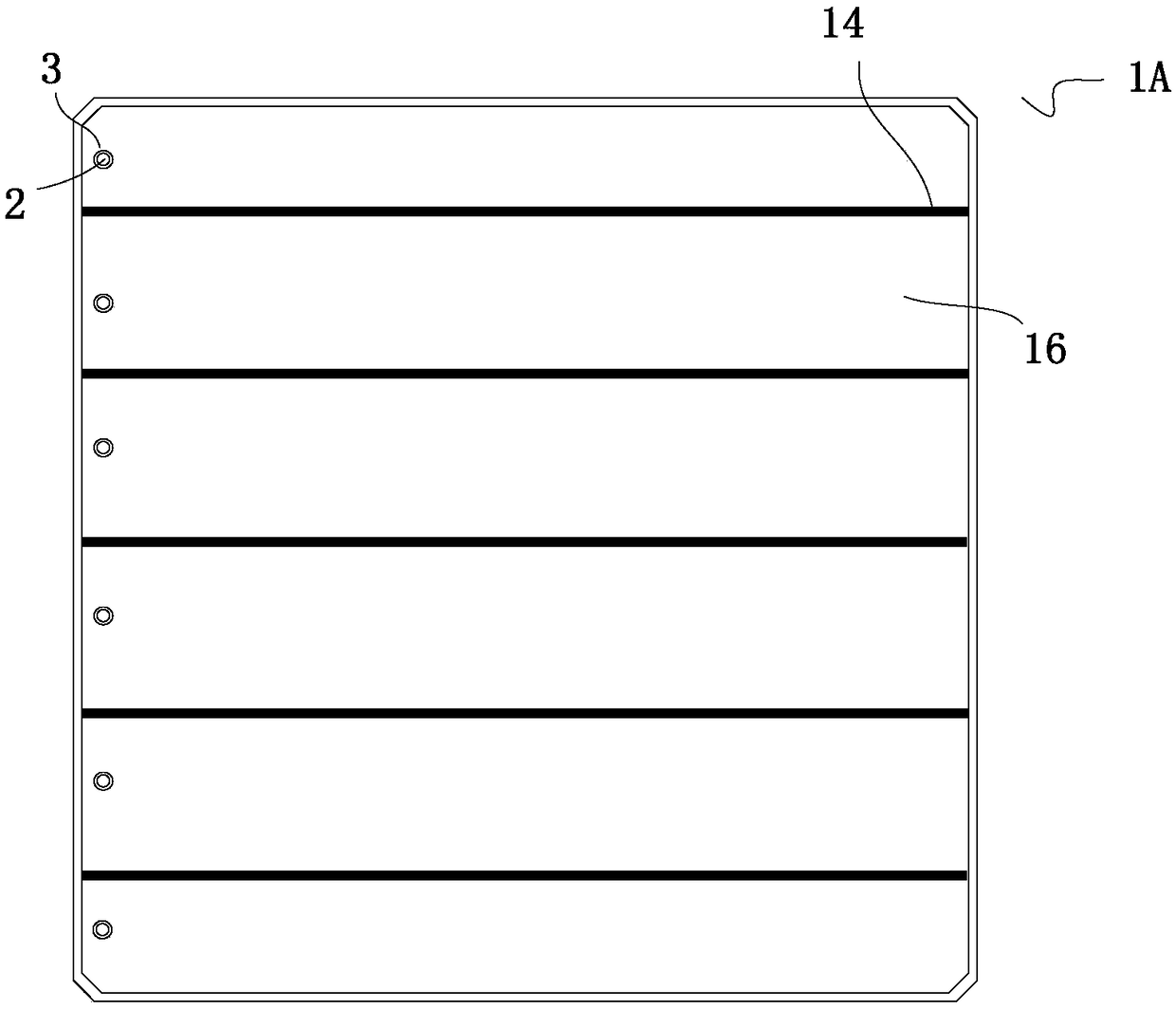

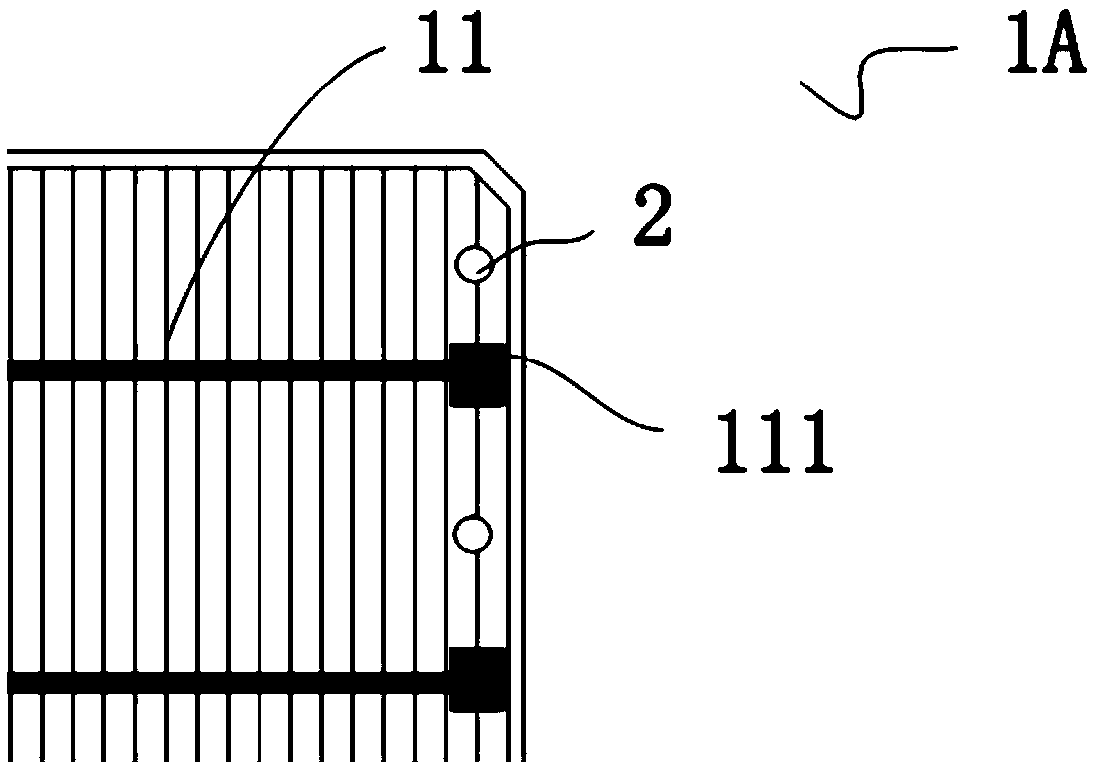

[0070] (1) The front electrode of the first solar battery sheet 1A includes a plurality of transverse front main grids 11, contacts 111 arranged at the ends of the transverse front main grids 11, and a plurality of longitudinal front sub-grids 13; the back electric field 16 is provided with a plurality of horizontal rear busbars 14, figure 1 , 2 The illustrated embodiment belongs to the case of (1).

[0071] (2) The front electrode of the first solar cell includes a plurality of transverse front main grids and a plurality of longitudinal front sub-grids; the back electric field is provided with a plurality of transverse rear main grids, and contacts arranged at the ends of the transverse rear main grids ;

[0072] (3) The front electrode of the first solar battery sheet includes a plurality of horizontal front main grids, contacts arranged at the ends of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com