Method for smoothing continuous ply rolling of metal-based composite plates

A metal-based composite plate and metal substrate technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of inability to realize continuous production, low bonding strength of plates, and large residual stress, etc., so as to facilitate the formulation And adjustment, high strength, promote the effect of metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

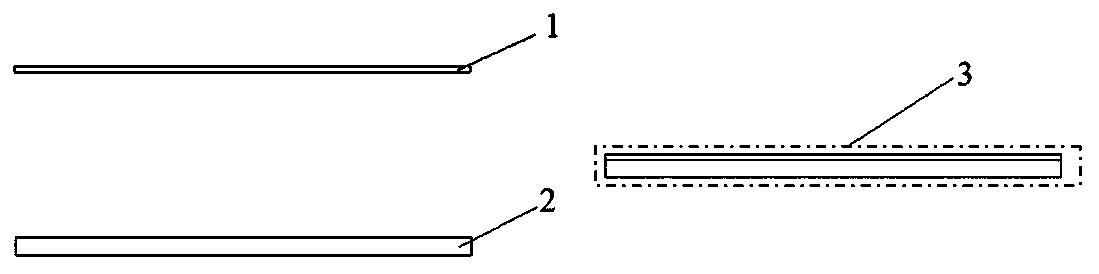

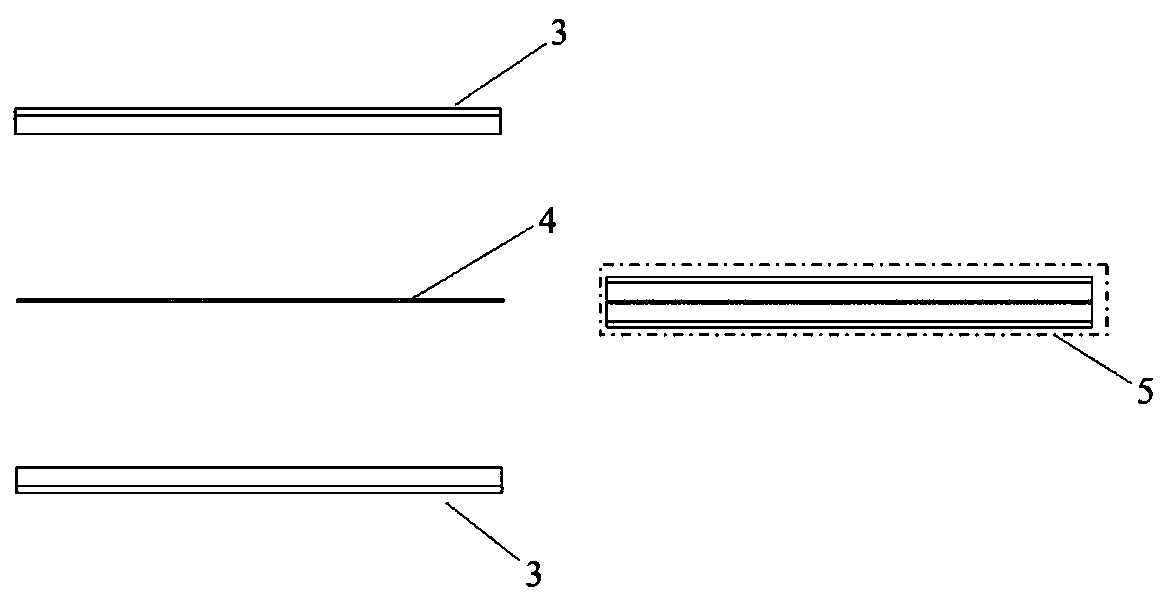

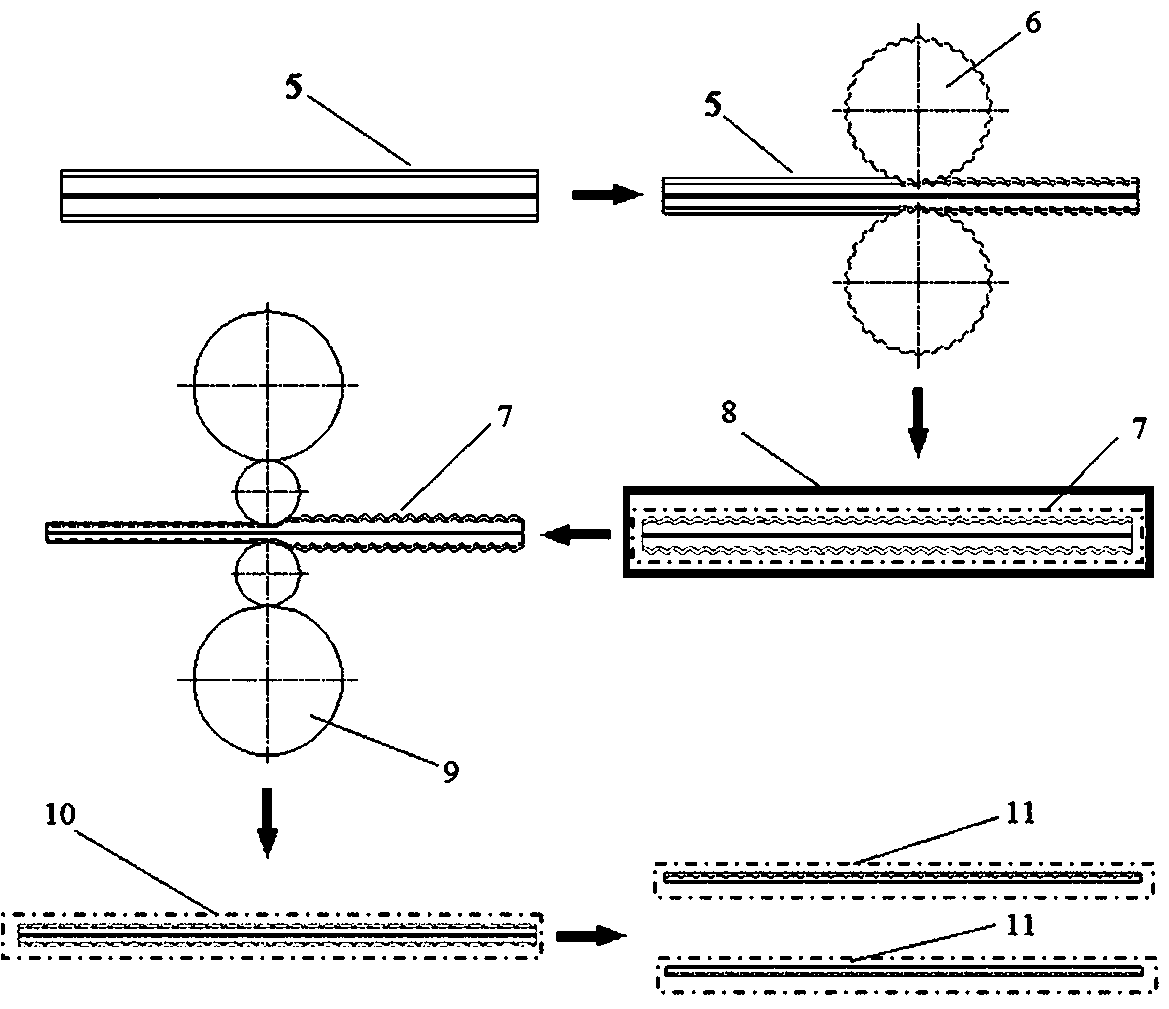

[0048] like figure 1 , 2 , 3, 4, 5, 6, adopt the method of the present invention to prepare carbon copper-aluminum composite board:

[0049] 1) Material: Select pure aluminum plate as the substrate 1, the plate size is 200mm (length) × 50mm (width) × 2mm (height), pure copper plate is used as the double plate 2, the plate size is 200mm (length) × 50mm (width) × 8mm (high). First, the cleaned pure copper plate and pure aluminum plate are subjected to stress relief annealing treatment in the heating furnace 8, so that the plate structure is more uniform, the plasticity of the plate is improved, and it is beneficial for the plate to realize compounding. Use a grinding tool equipped with a wire brush to grind the surface to be bonded of the pure copper plate and the pure aluminum plate after stress relief annealing to a “sand surface” effect to remove oxides on the surface of the slab and create favorable conditions for copper-aluminum compounding.

[0050] 2) Blank assembly: s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com