A kind of deplating solution, preparation method of deplating solution and deplating process

A deplating solution and process technology, applied in the field of deplating, can solve the problems such as the inconspicuous deplating effect, and achieve the effects of accelerating the speed of ink glass, reducing the rate of poor spraying, and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

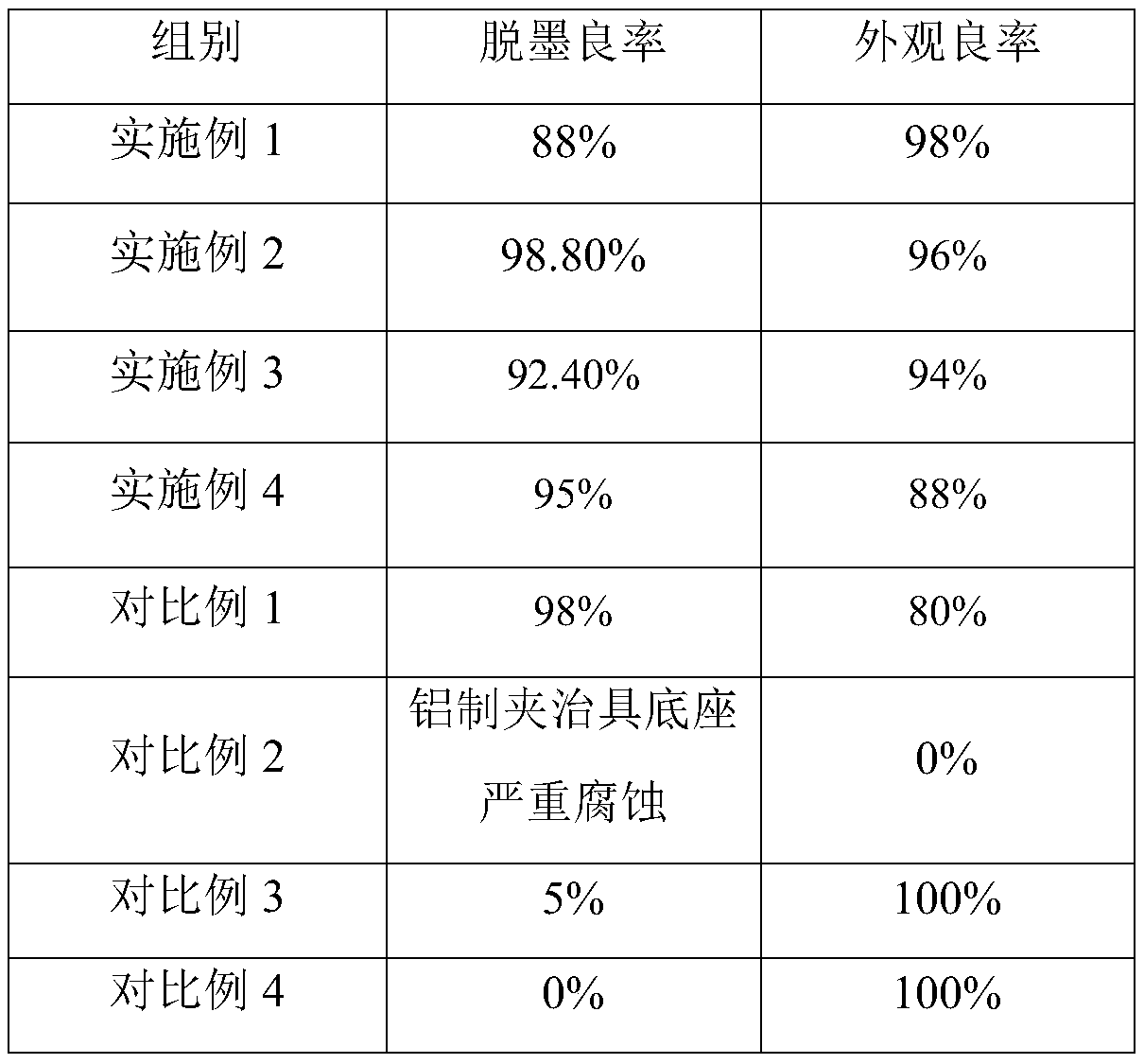

Examples

Embodiment 1

[0029] A kind of deplating solution, the deplating solution comprises the following components in terms of mass percentage: 2% of tetramethylammonium hydroxide, 1% of benzotriazole, 1% of sodium metasilicate pentahydrate, 5% of diethylene glycol %, diethylene glycol methyl ether 5%, alkyl glycoside 0.5%, water 85.5%.

[0030] The preparation method of the deplating solution is as follows, adding the weight of sodium metasilicate pentahydrate into water and stirring until completely dissolved, then adding tetramethylammonium hydroxide and alkyl glucoside, stirring until clear and transparent to obtain liquid A;

[0031] B. Stir the diethylene glycol and diethylene glycol methyl ether of the weight evenly, then add benzotriazole, stir until completely dissolved to obtain liquid B;

[0032] C. Mix liquid A and liquid B evenly and stir until completely clear.

[0033] This deplating process is specifically as follows, get the deplating solution stoste and use, record the pH value...

Embodiment 2

[0035] A stripping solution, the stripping solution comprises the following components in terms of mass percentage: 5% tetramethylammonium hydroxide, 2.5% benzotriazole, 5% sodium metasilicate pentahydrate, 15% diethylene glycol %, diethylene glycol methyl ether 15%, alkyl glycoside 1%, water 56.5%.

[0036] The preparation method of the stripping solution and the stripping process of this embodiment are the same as in Example 1.

Embodiment 3

[0038] A stripping solution, the stripping solution comprises the following components in terms of mass percentage: 7% tetramethylammonium hydroxide, 3% benzotriazole, 7% sodium metasilicate pentahydrate, 25% diethylene glycol %Diethylene glycol methyl ether 25%, alkyl glycoside 1.5%, water 31.5%.

[0039] The preparation method of the stripping solution and the stripping process of this embodiment are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com