Flue gas treatment system and method

A flue gas treatment system and flue gas treatment technology, applied in the field of boiler flue gas treatment, can solve problems such as unfavorable energy saving and emission reduction, unfavorable flue gas diffusion, and life troubles of surrounding residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

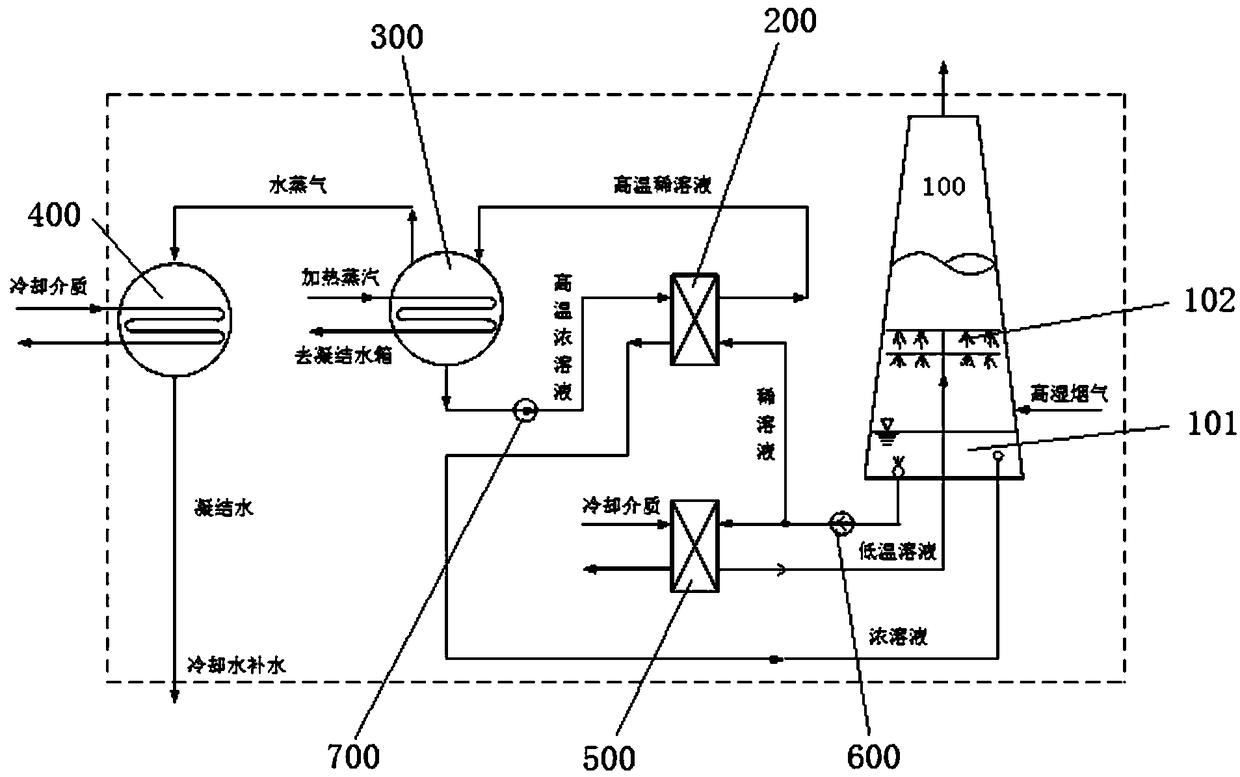

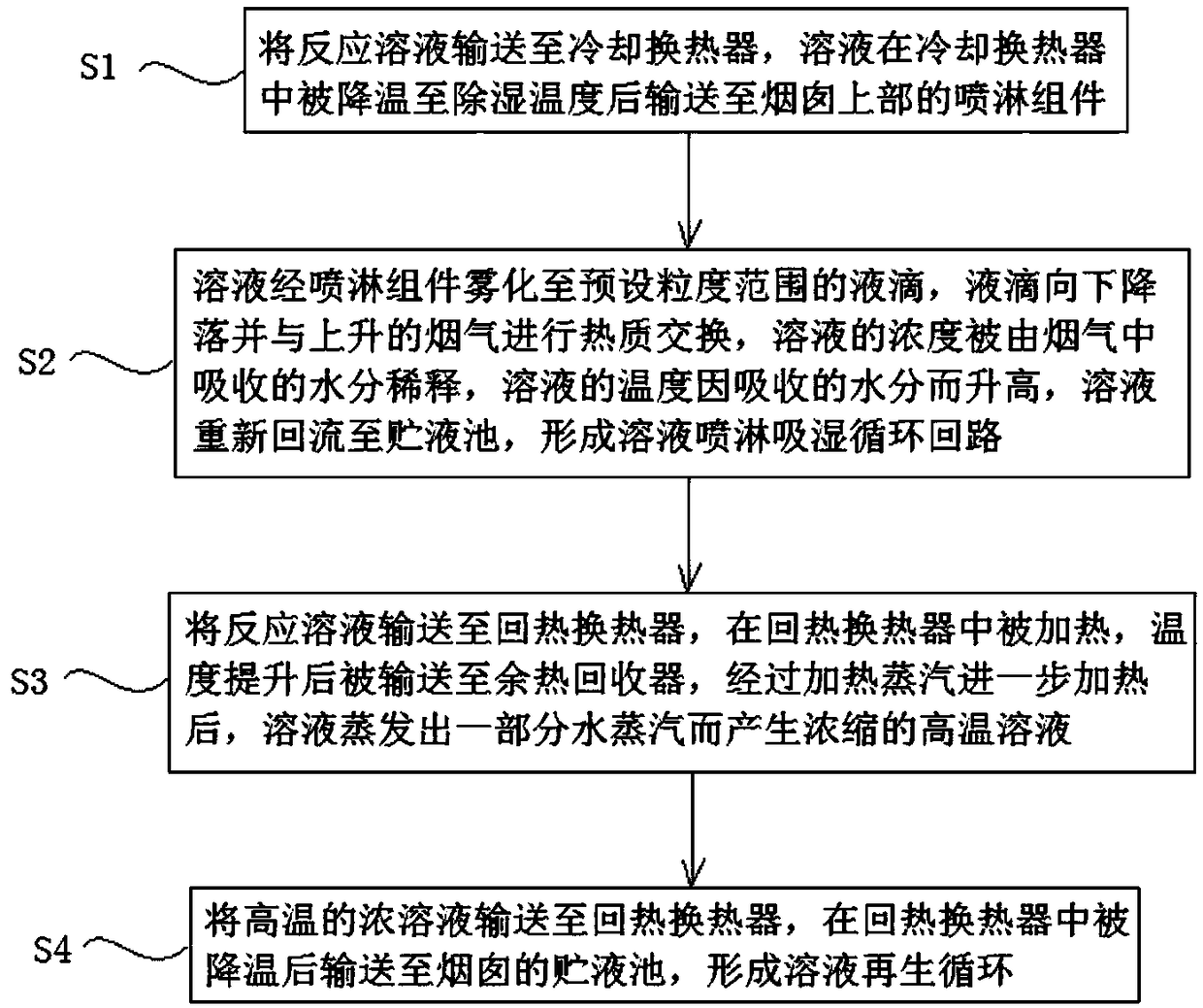

[0035] A flue gas treatment system of the present invention is used for a chimney (100), a dehumidification tower, a cooling heat exchanger (500) and a solution regeneration unit for circulation of flue gas to be treated;

[0036] The dehumidification tower includes a tower body, a spray assembly (102), a liquid storage tank (101) filled with a reaction solution, a smoke equalizer and a mist eliminator. The function of the dehumidification tower is to reduce the moisture content of the flue gas, that is, to us...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap