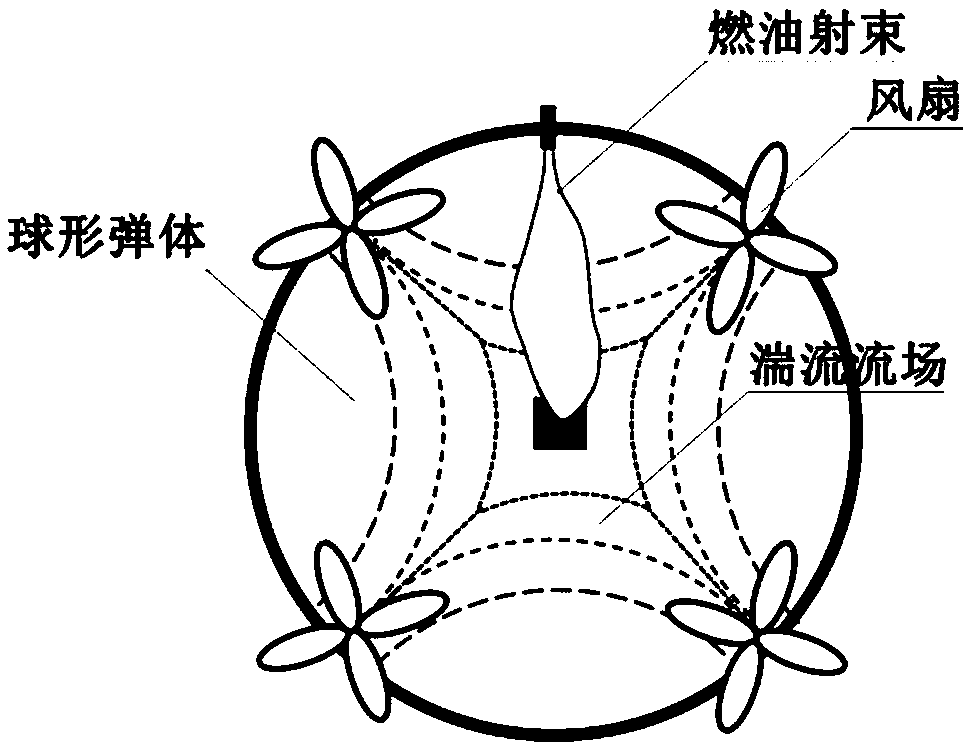

Constant volume experiment device capable of simulating injection and atomization processes in isotropic and anisotropic turbulent flow fields

An experimental device and isotropic technology, applied in the field of constant volume experimental devices, can solve the problems of difficult control of turbulence scale, complicated fan structure design, increased design burden and processing difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

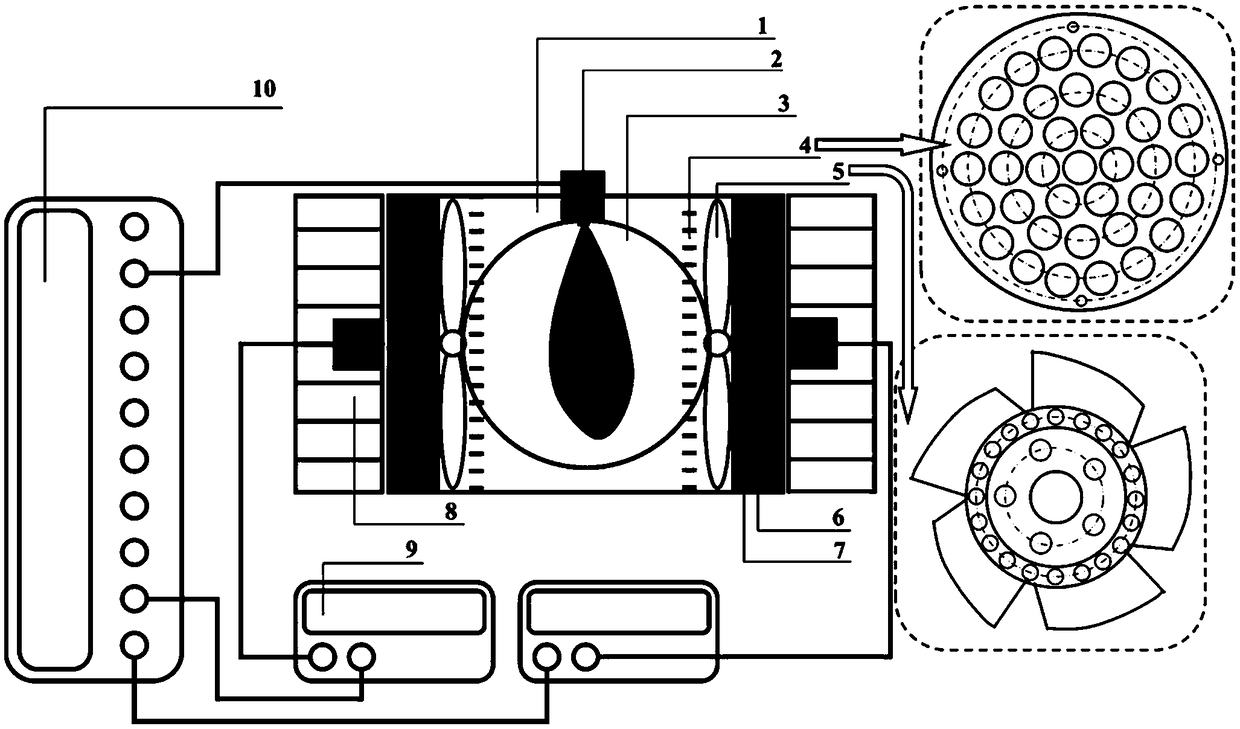

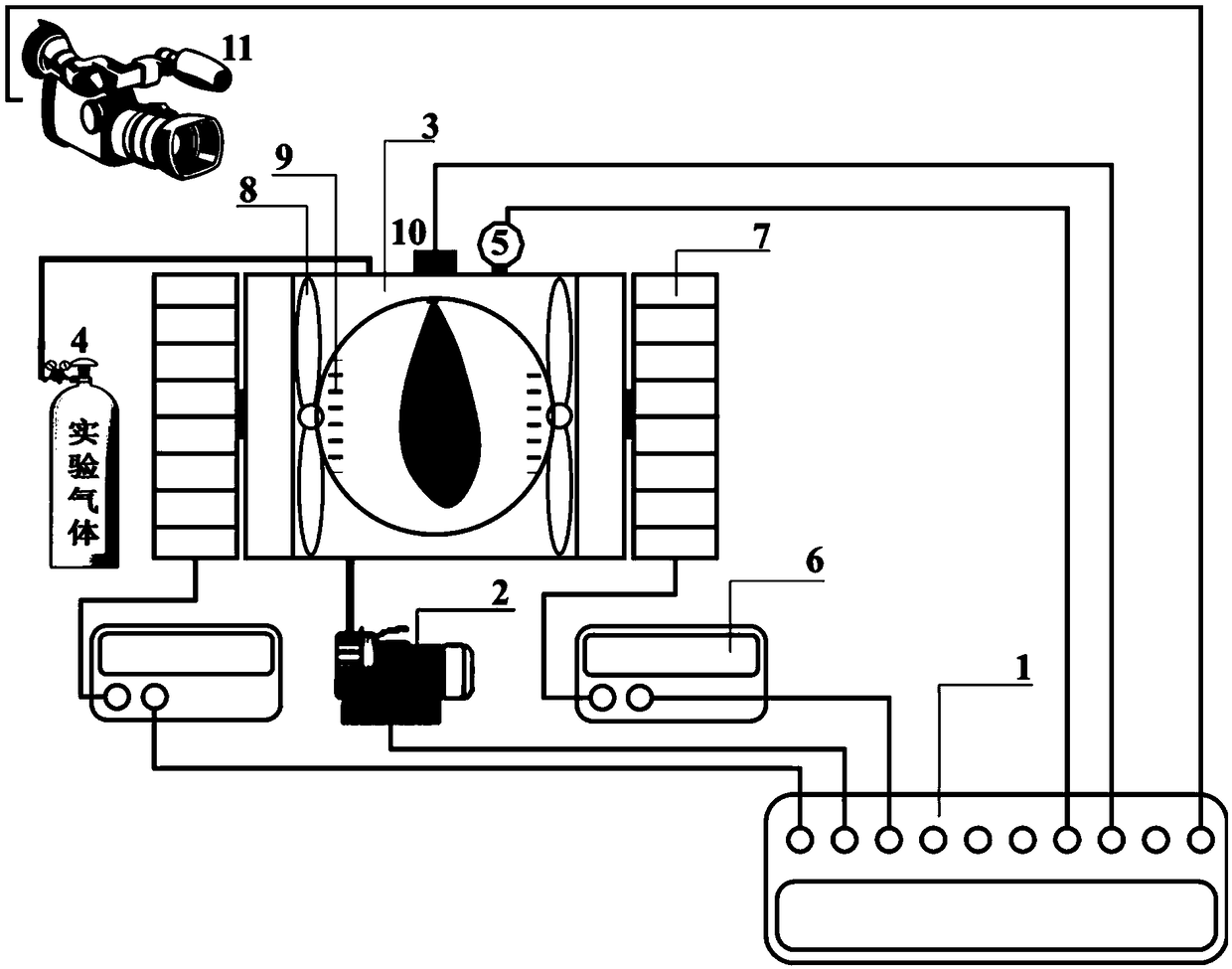

[0024] First, please refer to figure 2 , the structure of the constant volume experimental device for the study of the spray and atomization process in the isotropic turbulent flow field of a preferred embodiment of the present invention will be described in detail.

[0025] Specifically, the constant volume experimental device includes a cylindrical cavity 1, a fuel injector 2, an optical observation window 3, a porous orifice plate 4, an axial fan 5, a magnetic coupling 6, and a seal for the cylindrical cavity. End cover 7, rotating motor 8, frequency converter 9, electronic control unit 10. In this embodiment, the interior of the cylindrical cavity 1 is a cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com