Three-dimensional scanning laser radar based on MEMS micromirrors

A 3D scanning and lidar technology, applied in the field of 3D scanning lidar, can solve the problems of small plane size of MEMS micromirrors, difficult to achieve long-distance detection, and inability to control large-size light spots, etc., to achieve reliable quality, low power consumption, easy to use. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

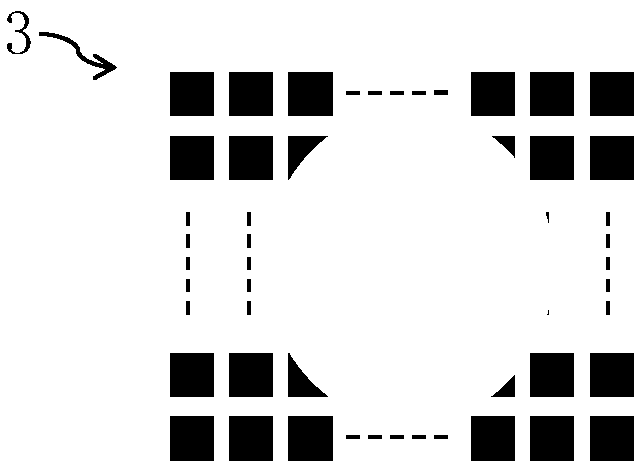

[0027] In order to solve the above problems, this embodiment proposes a two-dimensional MEMS small mirror array design scheme, such as figure 2 Shown. The MEMS micro-mirror is decomposed into multiple small micro-mirror units. Each small micro-mirror unit can be rotated at a large angle without taking up too much space in the thickness direction. It can be manufactured based on the existing semiconductor technology and is easy to mass produce. A small micro-mirror unit forms a large-size MEMS micro-mirror array 3, which can realize long-distance detection for large-size light spots, solves the application limitation of MEMS micro-mirrors in large-size light spot lidars, and helps realize long-distance detection of lidar .

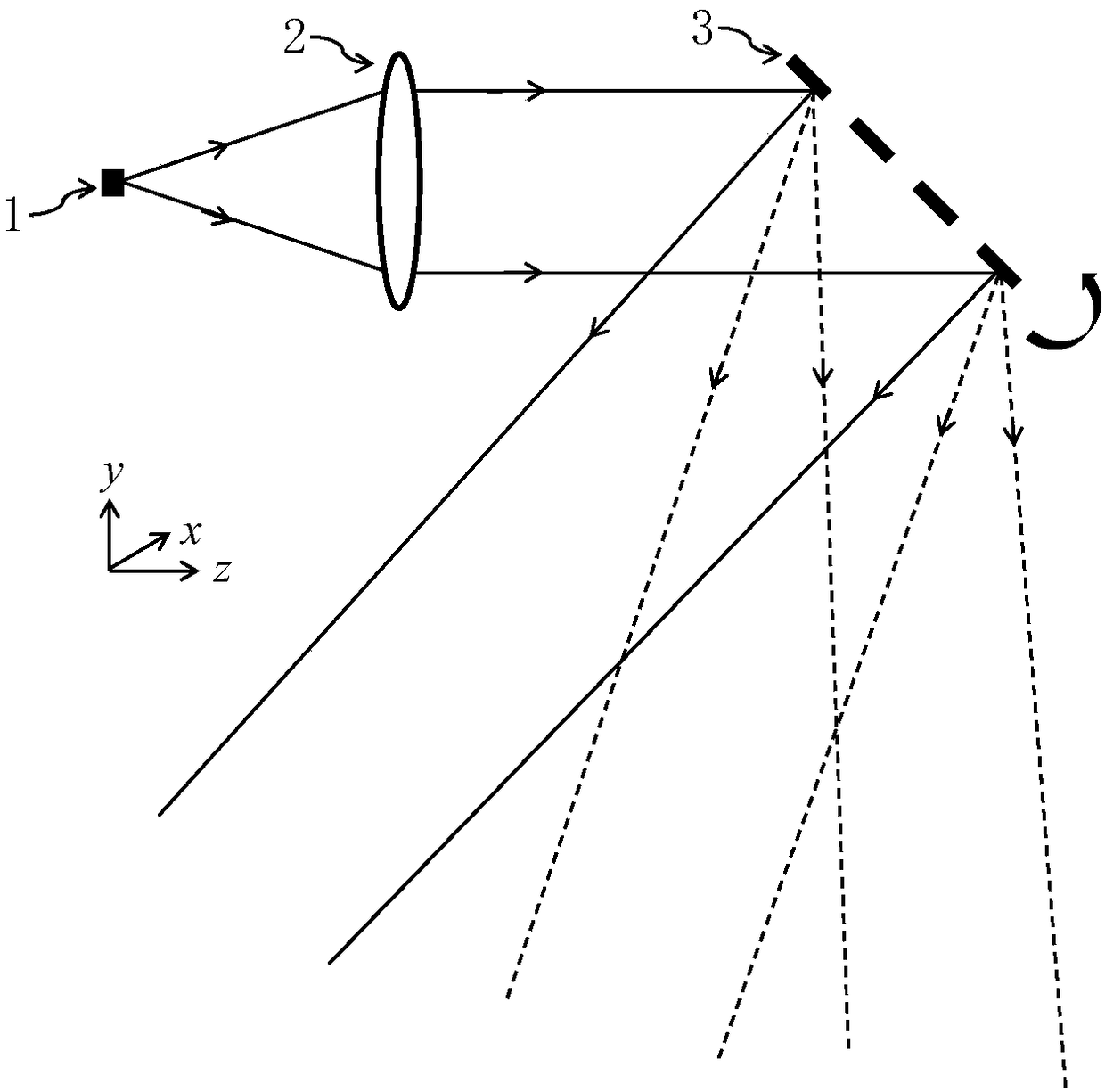

[0028] Such as figure 1 As shown, this embodiment provides a three-dimensional scanning lidar based on MEMS micromirrors, including a transmitting laser 1, a collimating optical element 2, a MEMS micromirror array 3, and a detector; the detection laser signal...

Embodiment 2

[0036] This implementation proposes a two-dimensional MEMS micro-mirror array design plan, which decomposes the MEMS micro-mirror into multiple small micro-mirror units. Each small micro-mirror unit can achieve large-angle rotation and does not occupy much space in the thickness direction. It can be manufactured based on the existing semiconductor technology and is easy to mass-produce. Multiple small micro-mirror units form a MEMS micro-mirror array 3.

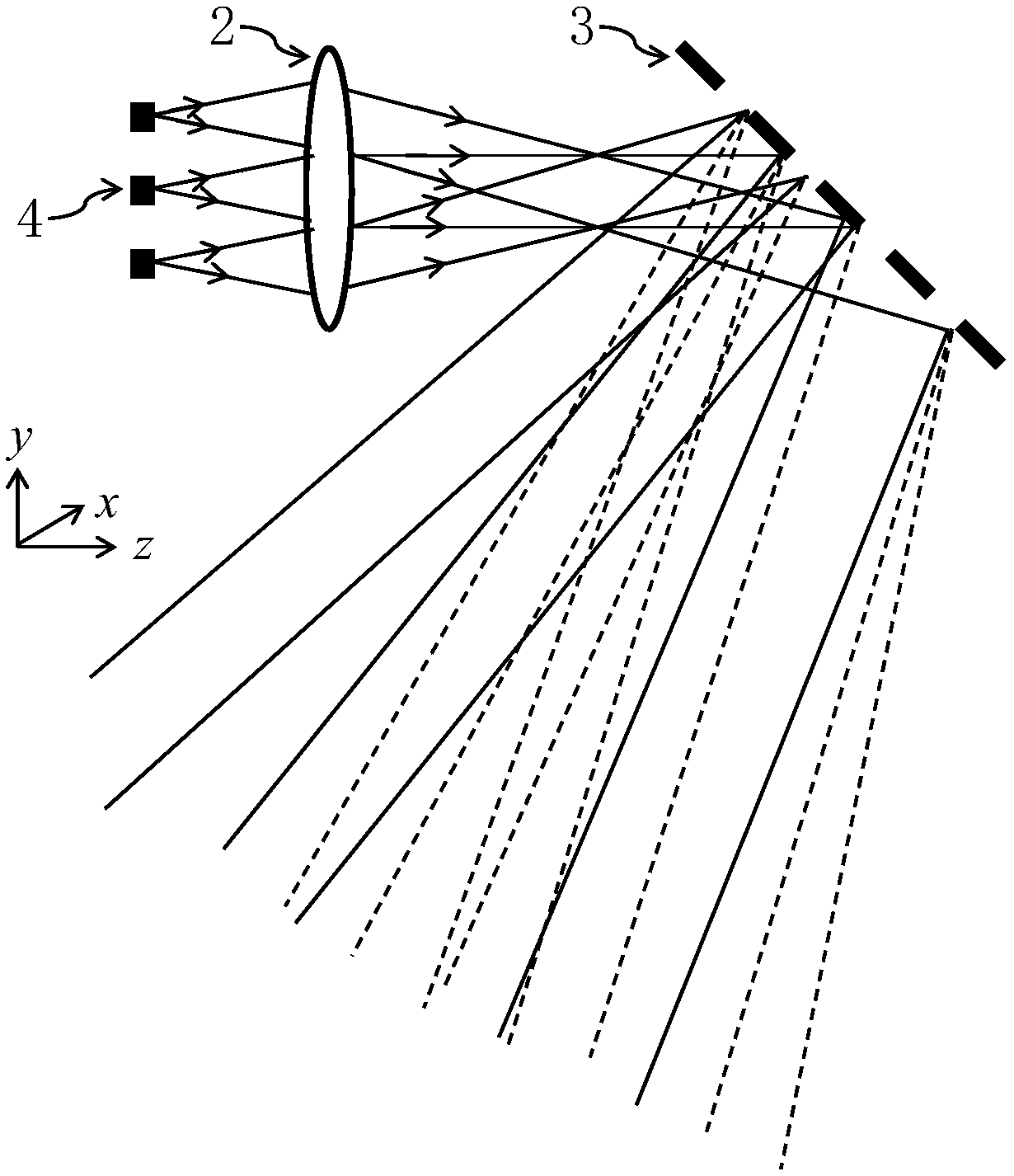

[0037] image 3 It is a schematic diagram of the optical path principle of Embodiment 2 of the MEMS micromirror-based three-dimensional scanning lidar of the present invention. Such as image 3 As shown, this embodiment provides a three-dimensional scanning lidar based on MEMS micromirrors, including a transmitting laser array 4, a collimating optical element 2, a MEMS micromirror array 3, and a detector; the detection laser signal emitted by the transmitting laser passes through the collimating optics The element (the collimati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com