An interferometric lithography system with controllable period and direction

A technology of interference lithography and cycle, applied in micro-lithography exposure equipment, optics, optomechanical equipment, etc., can solve the problems of long process cycle, expensive equipment, low production efficiency, etc., and achieve flexible and easy adjustment of the device, time reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

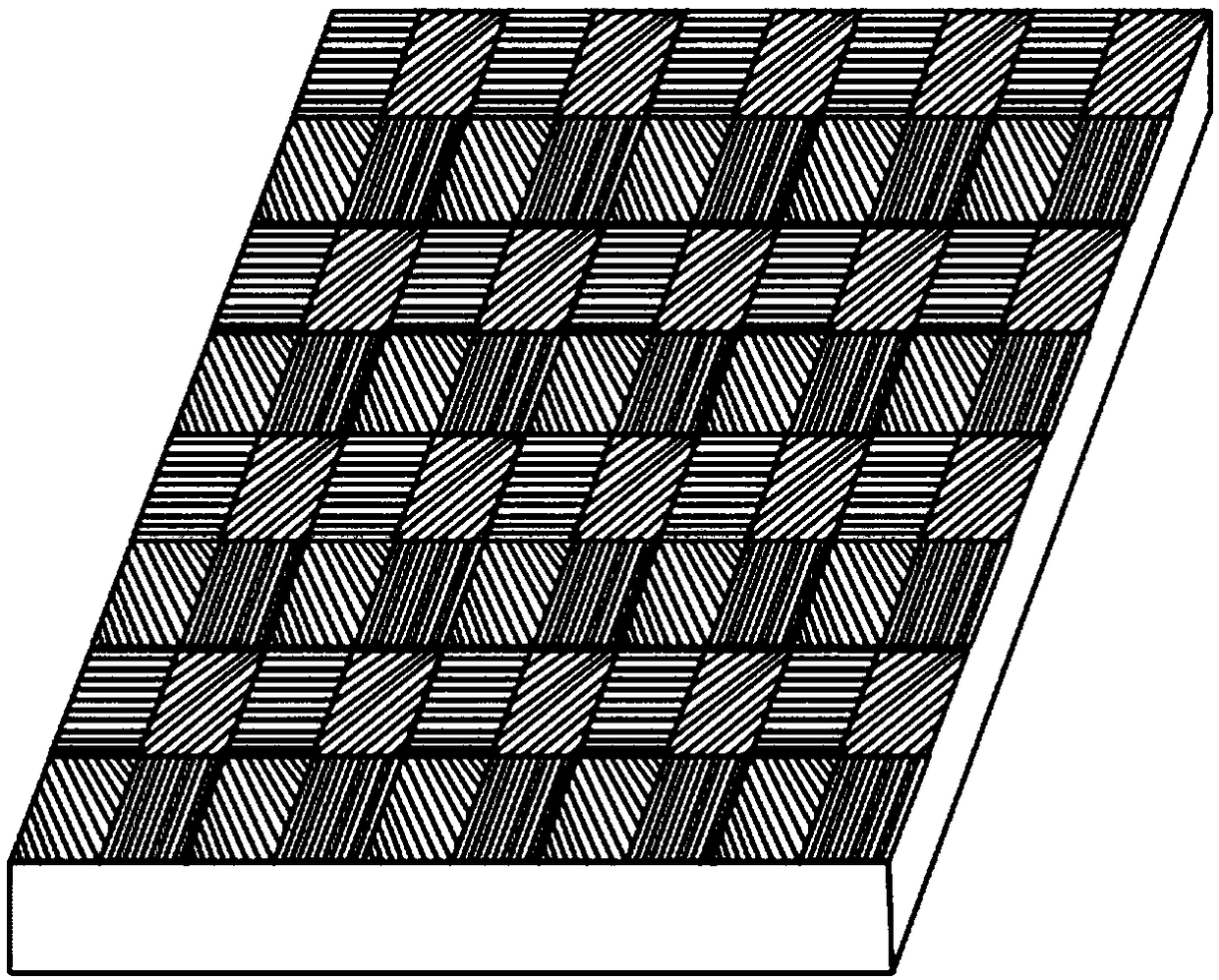

[0021] The invention proposes a method for preparing a grating with a 325nm wavelength laser, through the flexible control of the optical path, the purpose of flexibly changing the interference angle is achieved, thereby realizing the preparation of the grating with a controllable period and direction. In order to better understand the technical solution of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings.

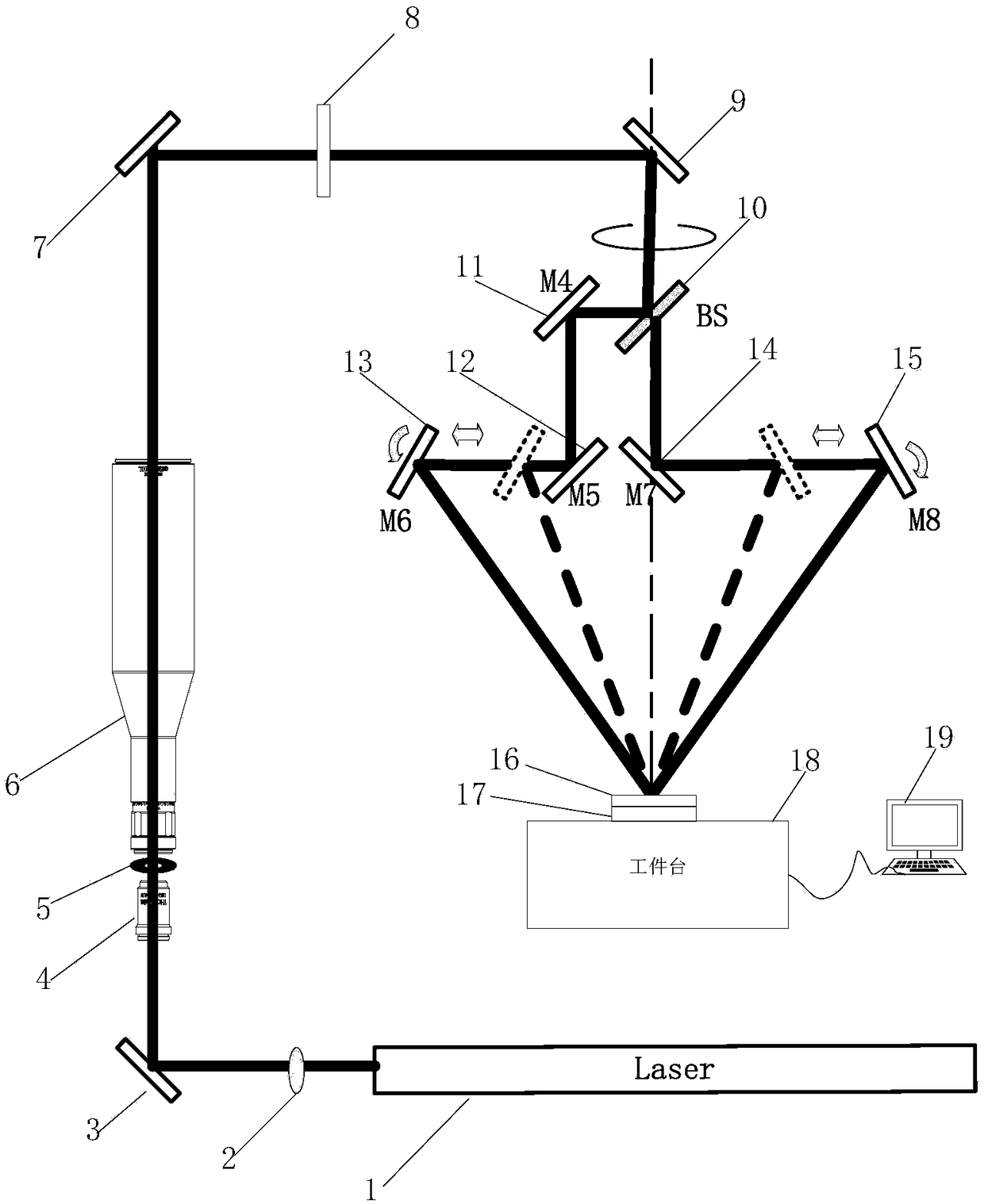

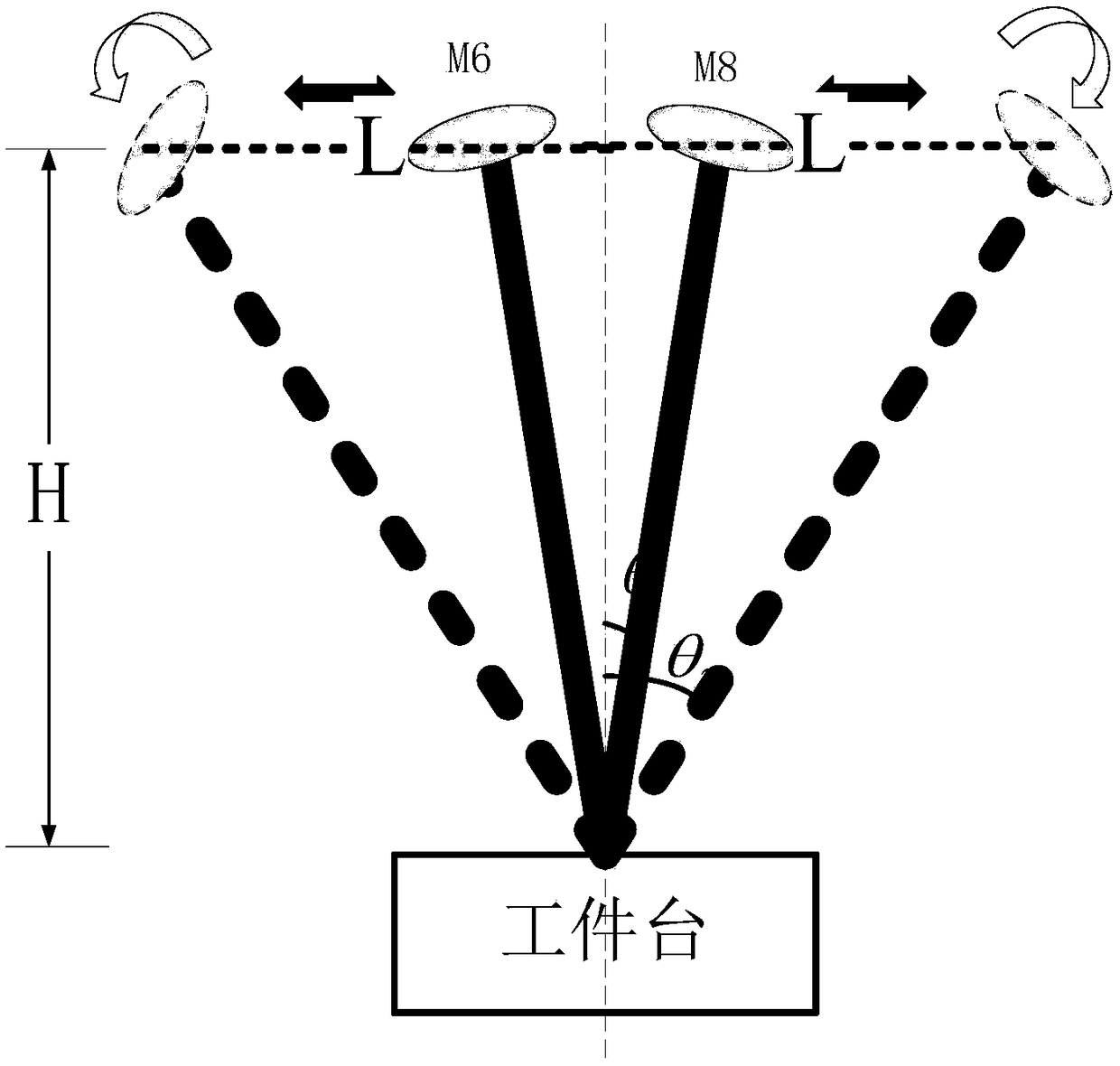

[0022] see figure 1 , is a schematic diagram of the optical path of an interference lithography system with controllable period and direction implemented in the present invention. Its system mainly includes laser 1, shutter 2, first mirror 3, ultraviolet focusing objective lens 4, pinhole 5, collimating mirror 6, second mirror 7, aperture 8, third mirror 9, beam splitter 10 , the fourth reflector 11, the fifth reflector 12, the sixth reflector 13, the seventh reflector 14, the eighth reflector 15, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com