Apolyvinylidene fluoride insulated electromagnetic filtering cable and a processing method thereof

A polyvinylidene fluoride, electromagnetic filtering technology, applied in the direction of insulated cables, insulated conductors, flexible cables, etc., can solve problems such as restricting development, prolong service life, improve electromagnetic filtering performance, and improve anti-complex electromagnetic Effect of Environmental Disturbance Level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

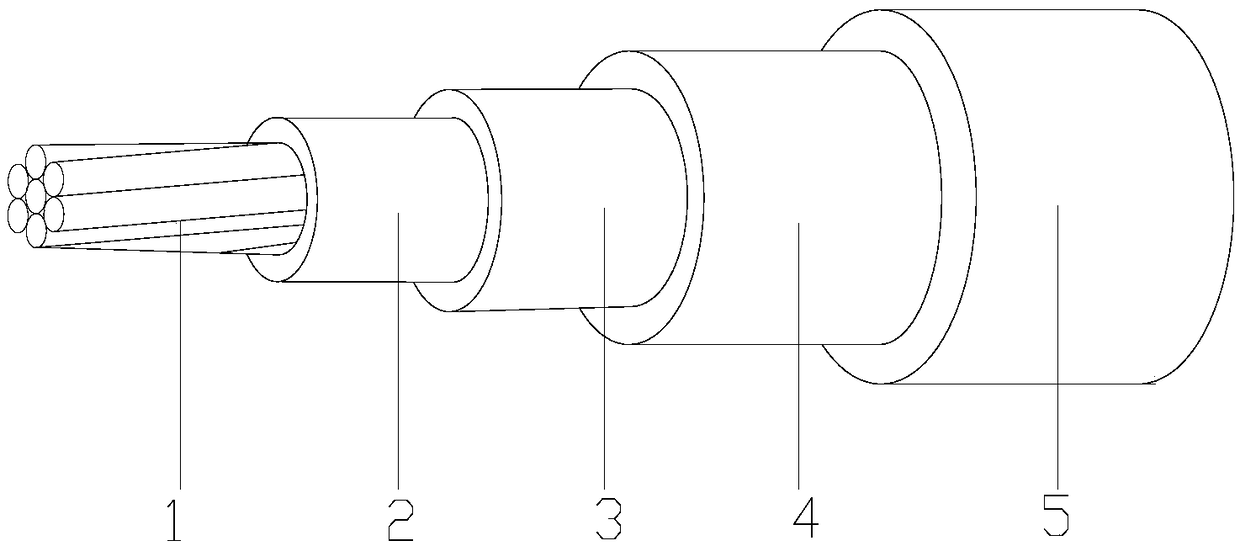

[0033] Structural Example 1: with reference to figure 1 , a polyvinylidene fluoride insulated electromagnetic filter cable, comprising a silver-plated copper alloy inner conductor 1, the surface of the inner conductor 1 is extruded with an insulating inner layer 2 made of polyvinylidene fluoride with a thickness of 0.01 mm, The surface of the insulating inner layer 2 is provided with an electromagnetic filter layer 3 with a thickness of 0.10mm made of filter composite material. Ferrite is evenly dispersed in the electromagnetic filter layer 3, and polyvinylidene fluoride is extruded outside the electromagnetic filter layer 3 The insulating outer layer 4 with a thickness of 0.05 mm is made of material, and the insulating outer layer 4 is extruded to form an outer sheath 5 made of cross-linked ethylene-tetrafluoroethylene material, a "sandwich" composed of an insulating inner layer, an electromagnetic filter layer, and an insulating outer layer The inner conductor protection str...

Embodiment 2

[0034] Structural Example 2: with reference to figure 1 , a polyvinylidene fluoride insulated electromagnetic filter cable, comprising a silver-plated copper alloy inner conductor 1, the surface of the inner conductor 1 is extruded with an insulating inner layer 2 made of polyvinylidene fluoride with a thickness of 0.18 mm, The surface of the insulating inner layer 2 is provided with an electromagnetic filter layer 3 with a thickness of 0.06mm made of filter composite material. Ferrite is evenly dispersed in the electromagnetic filter layer 3, and polyvinylidene fluoride is extruded outside the electromagnetic filter layer 3 The insulating outer layer 4 is made of 0.12 mm in thickness, and the insulating outer layer 4 is extruded with an outer sheath 5 made of cross-linked ethylene-tetrafluoroethylene.

Embodiment 3

[0035] Structural Example 3: with reference to figure 1, a polyvinylidene fluoride insulated electromagnetic filter cable, comprising a silver-plated copper alloy inner conductor 1, the surface of the inner conductor 1 is extruded with an insulating inner layer 2 of 0.15 mm thickness made of polyvinylidene fluoride, The surface of the insulating inner layer 2 is provided with an electromagnetic filter layer 3 with a thickness of 0.03mm made of filter composite material. Ferrite is evenly dispersed in the electromagnetic filter layer 3, and polyvinylidene fluoride is extruded outside the electromagnetic filter layer 3 The insulating outer layer 4 is made of 0.10mm thick material, and the insulating outer layer 4 is extruded with an outer sheath 5 made of cross-linked ethylene-tetrafluoroethylene.

[0036] Method embodiment 1:

[0037] A method for processing a polyvinylidene fluoride insulated electromagnetic filter cable, comprising the following steps:

[0038] 1) The inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com