A seawater corrosion resistance water-cooling method and insulated water-cooling resistor for a marine resistor sheet

A resistance sheet, seawater-resistant technology, applied in the direction of resistors, resistor parts, circuits, etc., can solve the problem that ship resistors cannot use seawater, etc., and achieve good insulation, small overall volume, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

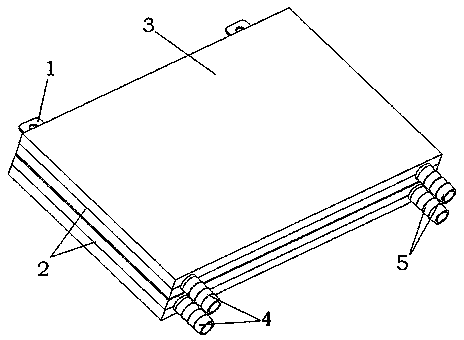

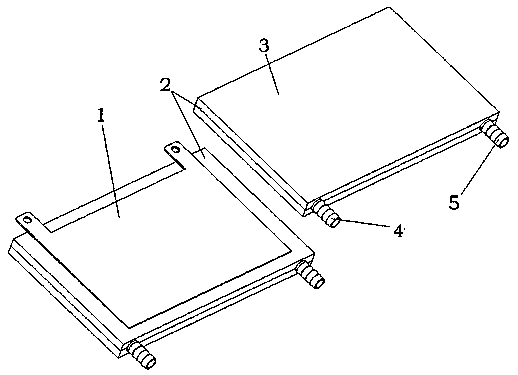

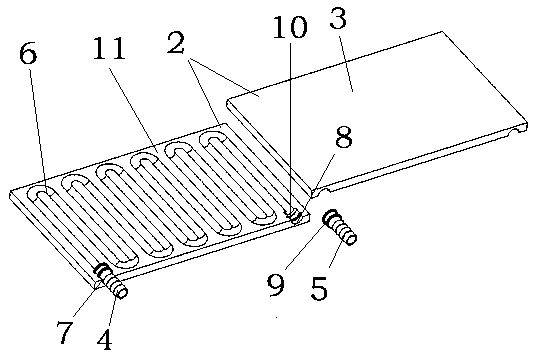

[0035] by attaching figure 1It can be seen that the present invention relates to an insulated water-cooled resistor of a seawater corrosion-resistant marine resistance sheet water cooling method, including a resistance sheet 1, and an insulating water-cooling radiator 2 is mounted on one or both sides of the resistance sheet 1. The water-cooled radiator 2 includes an insulated water-cooled radiator shell 3, a water inlet nozzle 4 and a water outlet nozzle 5; the insulated water-cooled radiator shell 3 is made of an insulating, corrosion-resistant and high-thermal conductivity aluminum nitride ceramic material, and adopts an upper and lower two-body combination structure, in the upper and lower two-body insulated water-cooled radiator shells, there are flow channels 6 for seawater circulation respectively, and the upper and lower two-body insulated water-cooled radiator shells are combined to form an insulated water-cooled radiator 2 with seawater flow channels; water inlets 4 a...

Embodiment 2

[0044] The principle of the second embodiment is the same as that of the first embodiment, except that the materials used and the water flow channels are different. It is an insulated water-cooled resistor, including a resistor sheet, and an insulating water-cooled radiator is mounted on one or both sides of the resistor sheet , the insulated water-cooled radiator includes an insulated water-cooled radiator housing, a water inlet nozzle and a water outlet nozzle; the insulated water-cooled radiator housing is made of insulating, corrosion-resistant and highly thermally conductive alumina ceramics or alumina-zirconia composite ceramic materials The production adopts the upper and lower two-body combined structure, and there are flow channels for seawater circulation in the upper and lower two-body insulating water-cooling radiator shells, and the upper and lower two-body insulating water-cooling radiator shells are combined to form an insulated water-cooling radiator with seawate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com