A method for preparing ultra-thin porous nickel selenide nanosheet array by etching manganese-doped nickel hydroxide

A technology of nanosheet array and nickel hydroxide, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of inability to have porosity, few contact active sites, and low capacitance performance, so as to increase the cycle The effects of stability, improved capacitance performance, and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Embodiment 1: A method of preparing ultra-thin porous nickel selenide nanosheet arrays by etching manganese-doped nickel hydroxide in this embodiment is carried out in the following steps:

[0037] 1. Preparation of reaction solution:

[0038] Adding nickel nitrate, manganese chloride and cetyltrimethylammonium bromide into the mixed solution and fully mixing to obtain a reaction solution;

[0039]The total concentration of nickel nitrate and manganese chloride in the described reaction solution is 0.03mmol / mL~0.05mmol / mL; The concentration ratio of described nickel nitrate and manganese chloride is 1:(1~7); The described The concentration of cetyltrimethylammonium bromide in the reaction solution is 0.05mmol / mL~1.4mmol / mL; The mixed solution is a mixed solution of methanol and water, and the volume ratio of methanol and water in the mixed solution is 1:(1~6);

[0040] 2. Preparation of manganese-doped nickel hydroxide nanosheet arrays:

[0041] Immerse the nickel fo...

specific Embodiment approach 2

[0051] Embodiment 2: This embodiment differs from Embodiment 1 in that: the total concentration of nickel nitrate and manganese chloride in the reaction solution described in step 1 is 0.04 mmol / mL˜0.05 mmol / mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration ratio of nickel nitrate and manganese chloride described in step 1 is 1: (1-4). Others are the same as in the first or second embodiment.

PUM

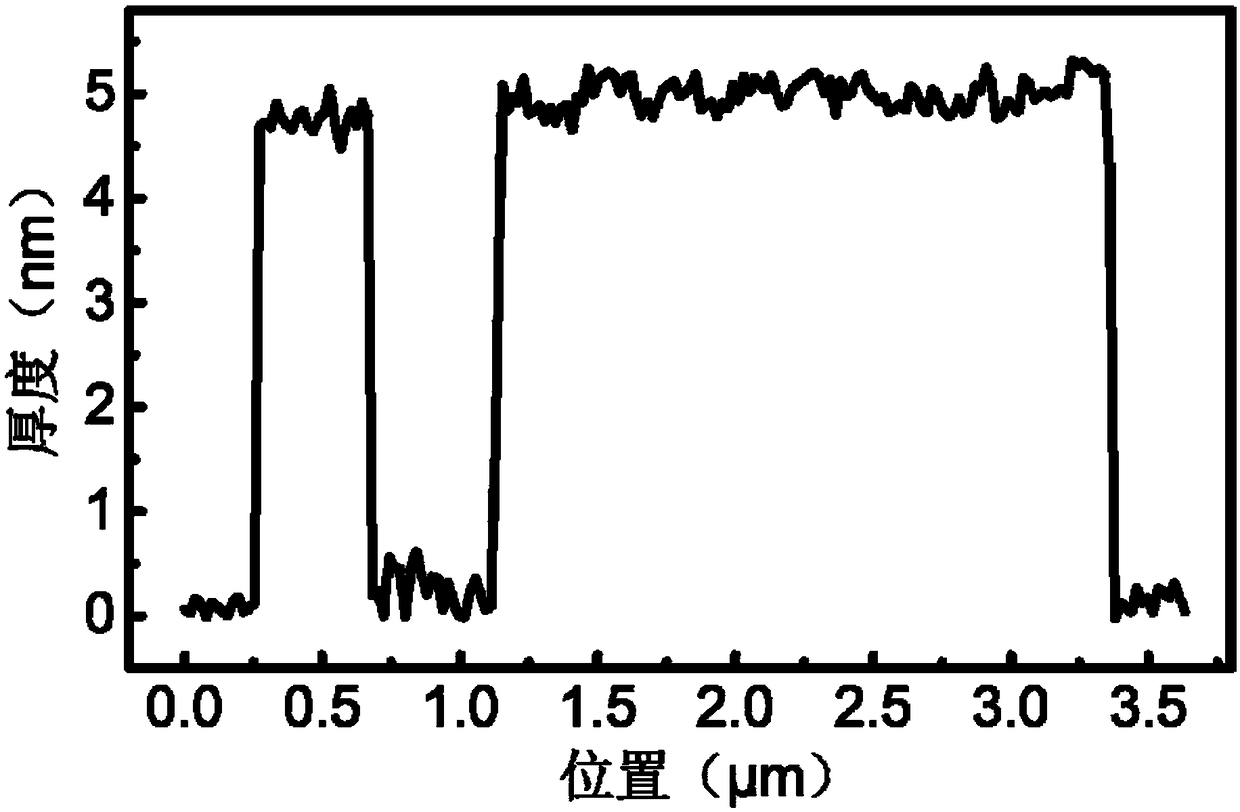

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com