Two-step method for preparing SmOCl photocatalyst

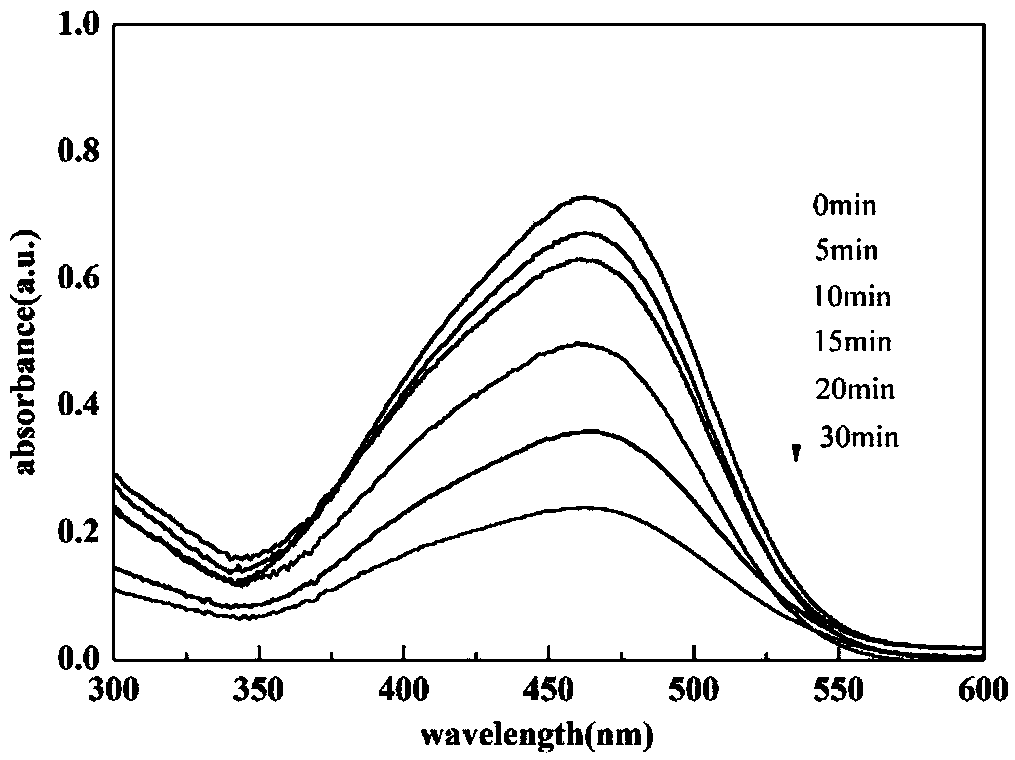

A photocatalyst, step-by-step technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve high-efficiency degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

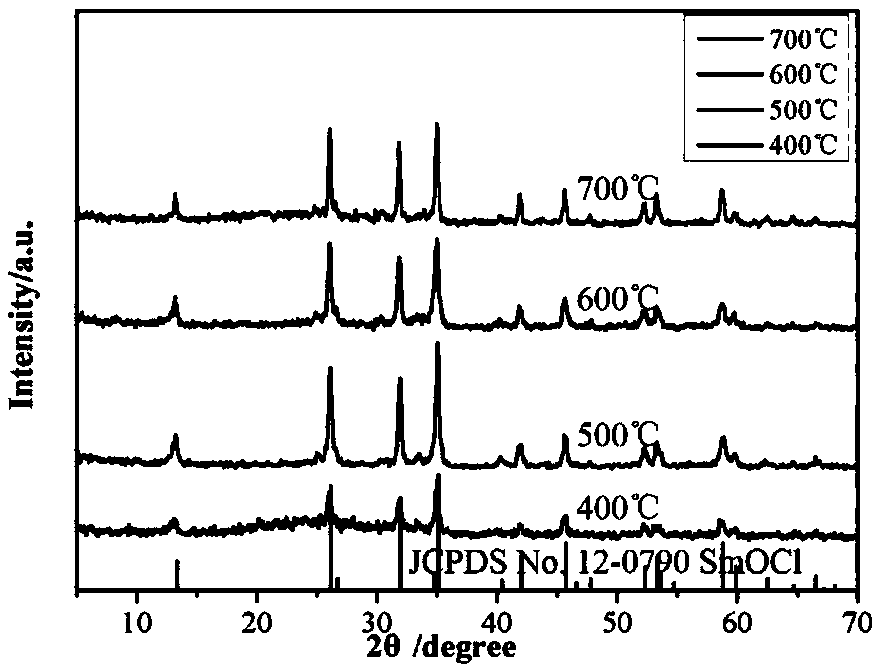

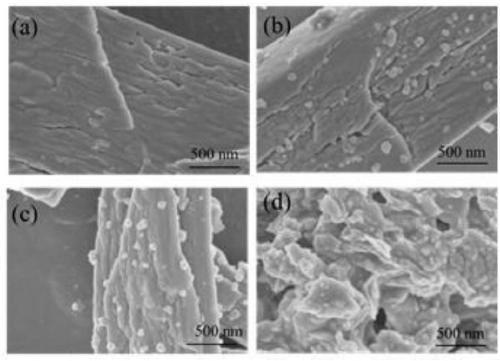

[0030] 1) Weigh 0.21mol of SmCl 3 ·6H 2 O, dissolved in 30ml of absolute ethanol to obtain Sm 3+ A solution with a concentration of 7 mol / L was stirred for 60 min to obtain solution A.

[0031] 2) Transfer the mixed solution A to a homogeneous hydrothermal kettle, put it into a homogeneous reactor, control the filling ratio at 30%, control the reaction temperature at 160° C., and react for 7 hours.

[0032] 3) After the reaction, the reactant was taken out, washed by deionized water and absolute ethanol for 5 times, and dried at 60° C. for 7 hours to obtain the precursor.

[0033] 4) The dried precursor was calcined in a horse boiling furnace, the calcining temperature was controlled at 400° C., and the calcining time was 70 min to obtain a photocatalyst of SmOCl.

Embodiment 2

[0035] 1) Weigh 0.255mol of SmCl 3 ·6H 2 O, dissolved in 35ml of absolute ethanol to obtain Sm 3+ A solution with a concentration of 7.3mol / L was stirred for 60 minutes to obtain solution A;

[0036] 2) Next, the mixed solution A was transferred to a homogeneous hydrothermal kettle, put into a homogeneous reactor, the filling ratio was controlled at 33%, the reaction temperature was controlled at 167° C., and the reaction was carried out for 8 hours.

[0037] 3) After the reaction is finished, the reactant is taken out, washed by deionized water and absolute ethanol for 6 times, and dried at 60° C. for 6 hours to obtain the precursor.

[0038] 4) The dried precursor was calcined in a horse boiling furnace, the calcining temperature was controlled at 500° C., and the calcining time was 75 min to obtain a photocatalyst of SmOCl.

Embodiment 3

[0040] 1) Weigh 0.28mol of SmCl 3 ·6H 2 O, dissolved in 37ml of absolute ethanol to obtain Sm 3+ A solution with a concentration of 7.50mol / L was stirred for 60 minutes to obtain solution A;

[0041] 2) Next, the mixed solution A was transferred to a homogeneous hydrothermal tank and put into a homogeneous reactor, the filling ratio was controlled at 36%, the reaction temperature was controlled at 174° C., and the reaction was carried out for 9 hours.

[0042] 3) After the reaction is finished, the reactant is taken out, washed by deionized water and absolute ethanol for 4 times, and dried at 60° C. for 5 hours to obtain the precursor.

[0043] 4) The dried precursor was calcined in a horse boiling furnace, the calcining temperature was controlled at 600° C., and the calcining time was 80 min to obtain a photocatalyst of SmOCl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com