Assembly type multicavity concrete-filled steel tubular member and preparation method thereof

A concrete-filled steel tube and prefabricated technology, which is applied to building components, elongated structural components used for load-bearing, structural elements, etc. mechanical properties, preventing local buckling, and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

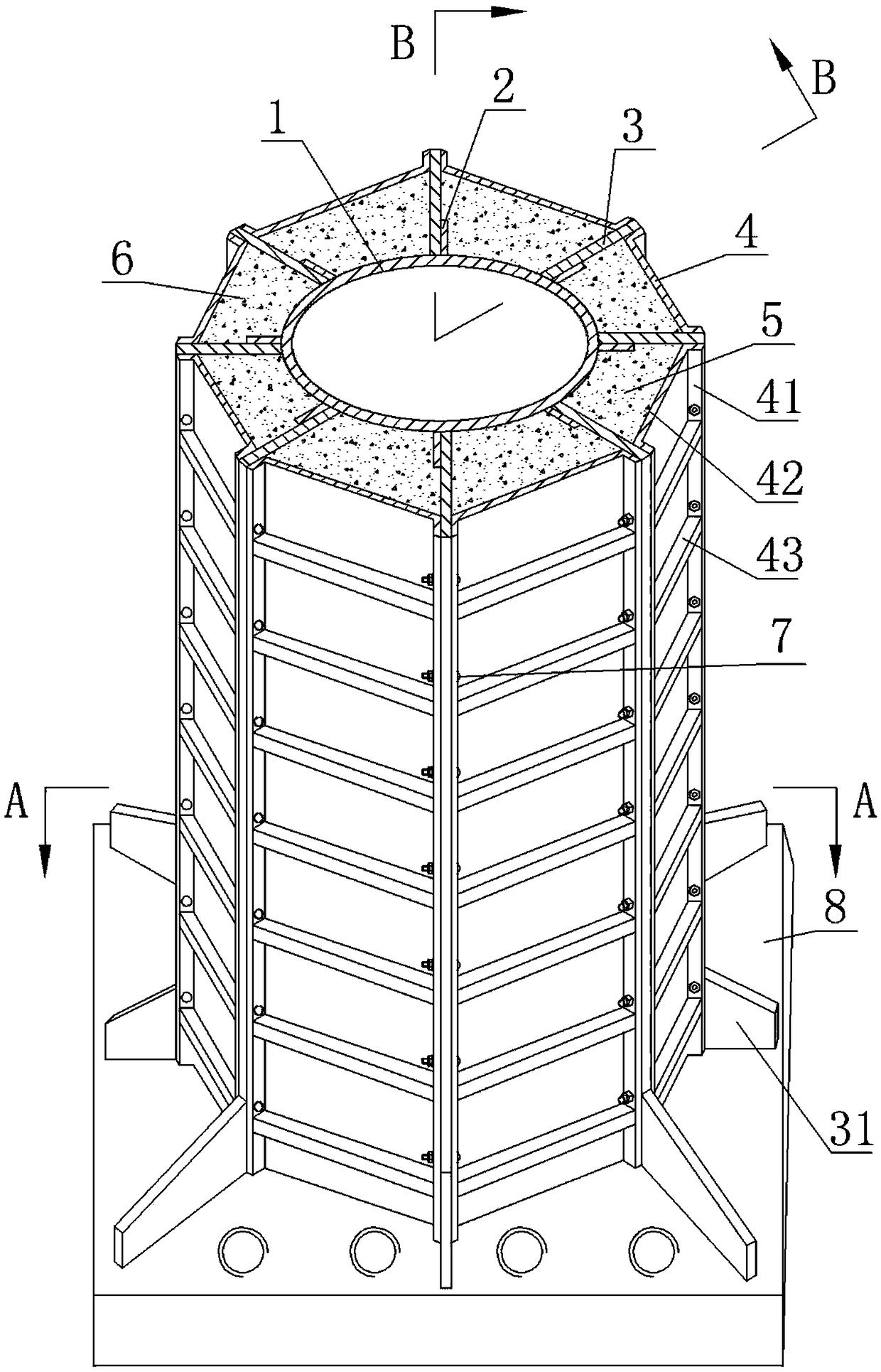

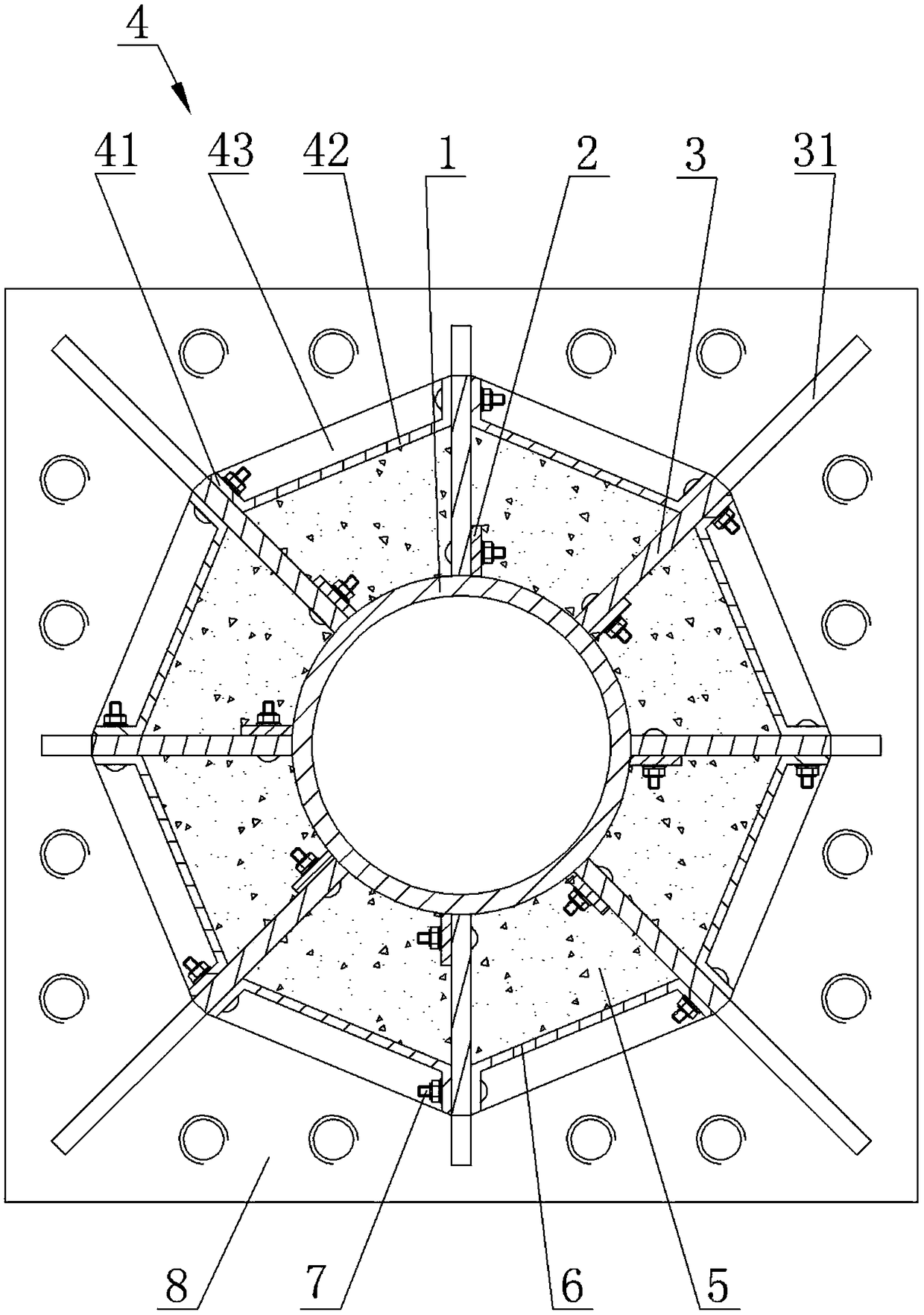

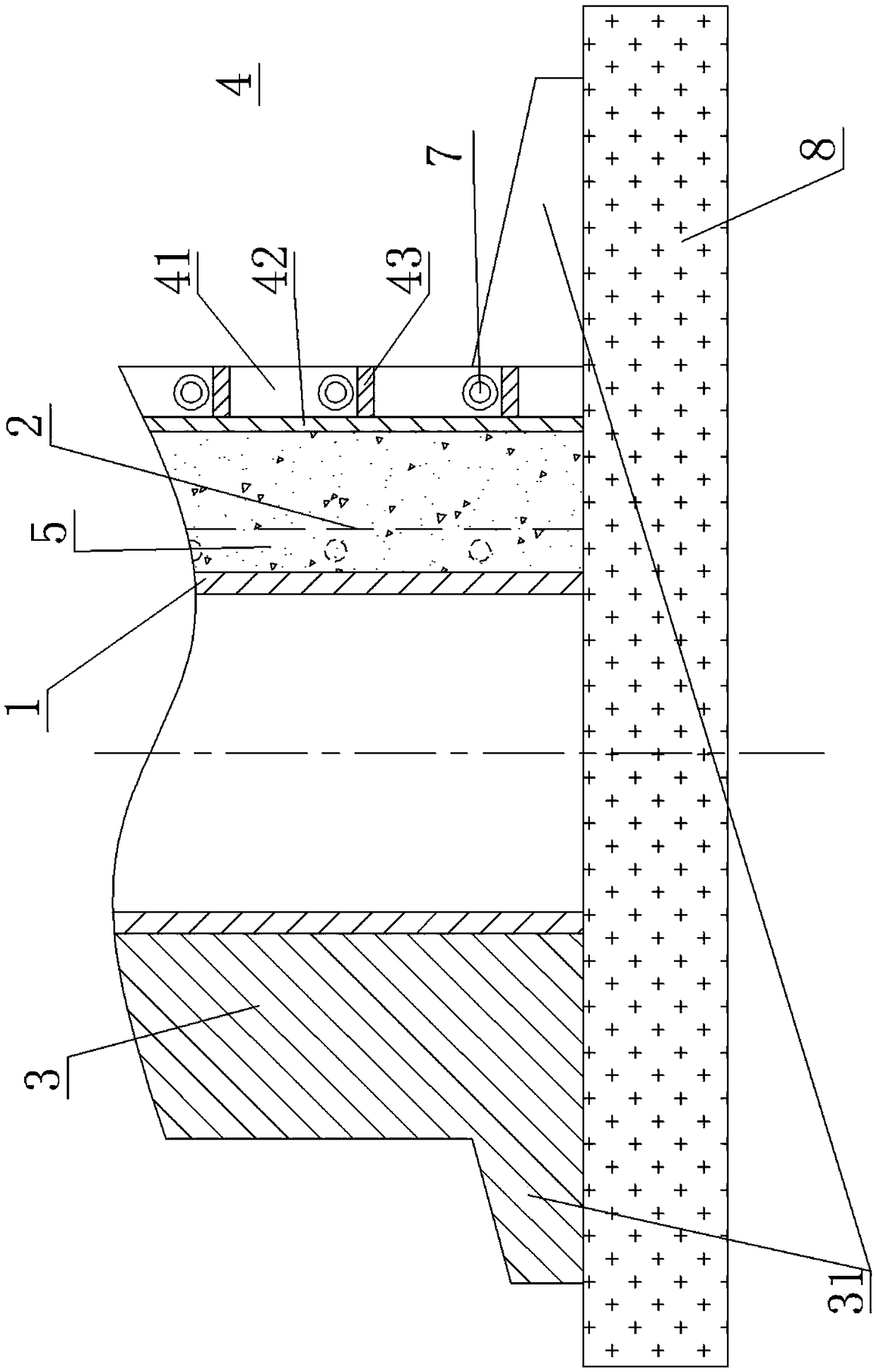

[0036] from Figure 1 to Figure 3 It can be seen that the prefabricated multi-cavity steel pipe concrete member of the present invention includes an inner steel pipe 1, a stiffened steel plate 2, a connecting steel plate 3, a channel steel 4, concrete 5 and frictional high-strength bolts 7,

[0037] Each stiffening rib steel plate 2 is vertically welded on the outer wall of the inner steel tube 1 along the axis of the inner steel tube 1, each stiffening rib steel plate 2 is evenly arranged around the axis of the inner steel tube 1, and is uniformly opened on each stiffening rib steel plate 2 in the axial direction. There are several bolt holes,

[0038] The inner end of the connecting steel plate 3 is fastened and connected to each stiffener steel plate 2 through friction type high-strength bolts 7, the transverse direction of the connecting steel plate 3 is arranged radially along the inner steel pipe 1, and the longitudinal direction of the connecting steel plate 3 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com