Preparation method for work softening low-carbon steel

A technology of low carbon steel and carbon content, which is applied in the field of metal materials and can solve the problems of reduced toughness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Select 15 low-carbon steel, the weight percentage of its chemical composition is: C 0.13%, Si 0.08%, Mn 0.13%, P0.01%, S0.004%, the balance is Fe, heated to 920 ° C for 1 hour, after Quenching with 10% sodium chloride in ice water to obtain lath martensite; cold rolling at room temperature, the deformation amount is 80%, and its structure is C supersaturated deformed ferrite lath arranged in parallel; tempering at 400°C to obtain pancake Shaped grain low carbon steel plate.

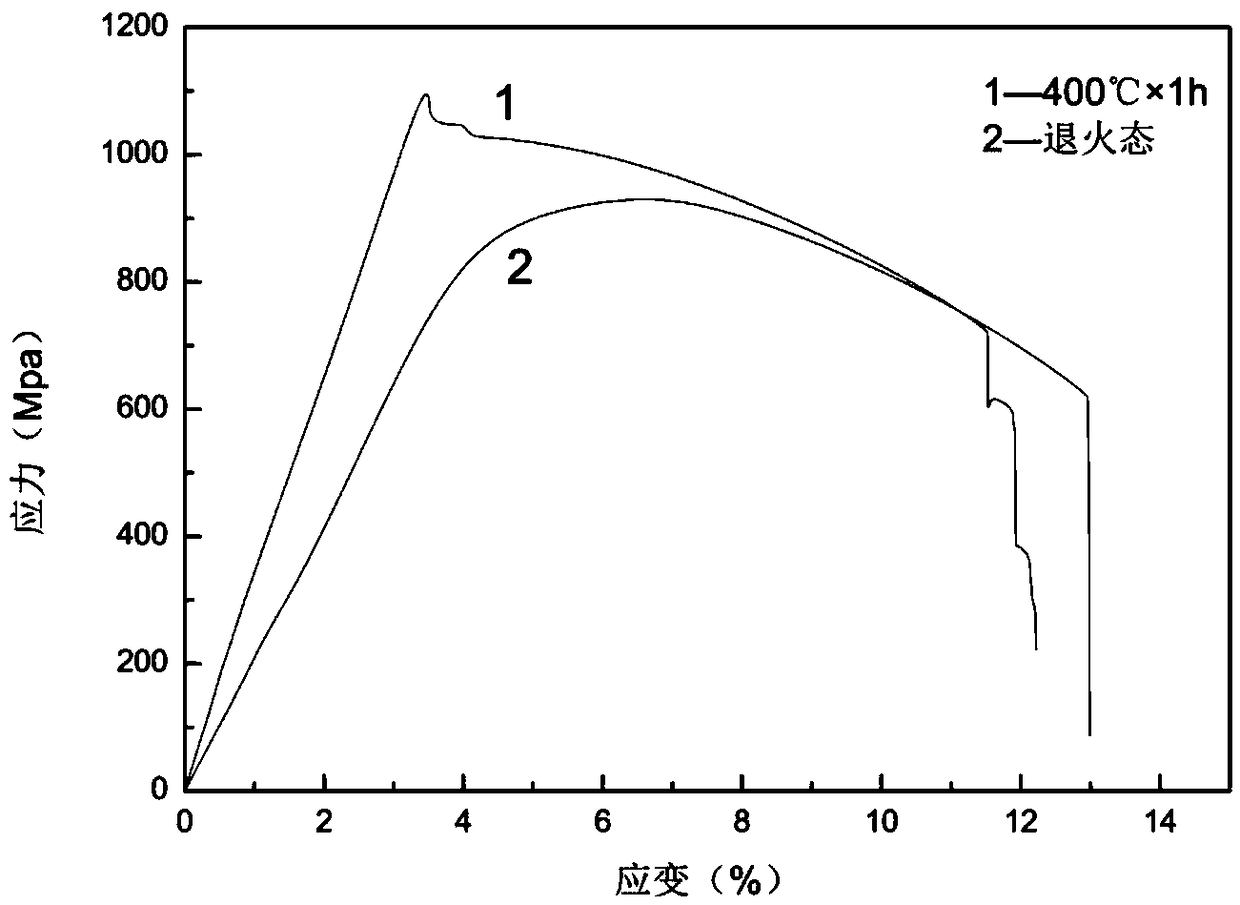

[0022] Such as figure 1 As shown, 1 is the curve of the prepared low carbon steel, which decreases in strength with the increase of strain after the yield point, and has the characteristics of work softening; as a comparison, 2 is the curve of the same low carbon steel in annealed state, and the strength increases with the strain after the yield point Increased height, a classic work hardening feature.

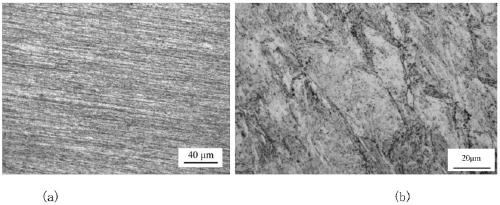

[0023] Such as figure 2 As shown, a) the metallographic structure of the steel plate side, ...

Embodiment 2

[0028] Choose No. 15 low-carbon steel, the weight percentage of its chemical composition is: C 0.13%, Si 0.08%, Mn 0.13%, P 0.01%, S 0.004%, the balance is Fe, heated to 920 ° C for 1 hour, after 10 % sodium chloride ice water quenching to obtain lath martensite, cold rolling at room temperature, the deformation amount is 80%, and its structure is parallel arrangement of C supersaturated deformed ferrite lath, tempering at 200 ° C to obtain pancake-shaped crystal grain low carbon steel plate.

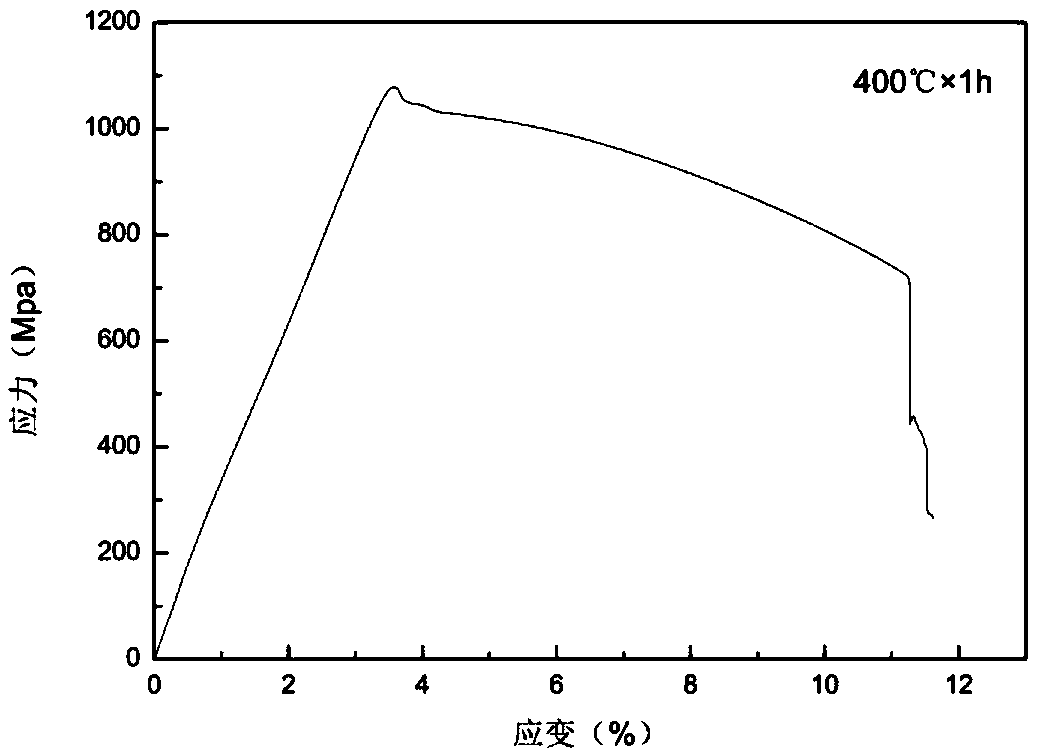

[0029] Measure the tensile stress-strain curve at room temperature, such as Figure 4 Its mechanical properties are shown in Table 2.

[0030] Table 2 Mechanical properties of 15 steel quenched-80% deformation-200℃ tempering

[0031]

Embodiment 3

[0033] Choose No. 15 low-carbon steel, the weight percentage of its chemical composition is: C 0.13%, Si 0.08%, Mn 0.13%, P 0.01%, S 0.004%, the balance is Fe, heated to 920 ° C for 1 hour, after 10 % sodium chloride ice water quenching to obtain lath martensite, cold rolling at room temperature, the deformation amount is 80%, and its structure is C supersaturated deformed ferrite lath arranged in parallel, tempering at 300 ° C to obtain pancake-shaped crystal grain low carbon steel plate.

[0034] Measure the tensile stress-strain curve at room temperature, such as Figure 5 Its mechanical properties are shown in Table 3.

[0035] Table 5 Mechanical properties of 15 steel quenched - 80% deformation - 300 ℃ tempering

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com