PVC leather and manufacturing method and application thereof

A leather and foam layer technology, applied in the field of artificial leather, can solve the problems of non-environmental protection and harmfulness, and achieve the effects of low VOC, low odor, good wear resistance and hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

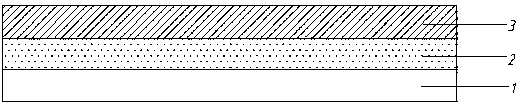

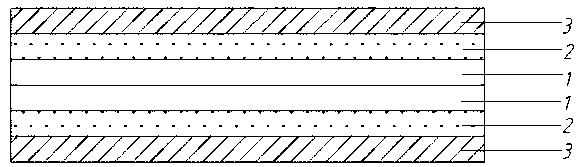

[0070] In order to manufacture PVC leather that does not use adhesive bonding when being applied to automobile curtains, the present invention also provides a kind of preparation method of above-mentioned PVC leather: adopt calender molding process, comprise the following steps:

[0071] Step 1: Prepare the raw materials required for the foam layer and the surface layer respectively according to the weight ratio.

[0072] The foam layer includes the following raw materials in parts by weight: 38-50 parts of SG-5 type PVC resin, 19-25 parts of plasticizer, 23-30 parts of filler, 0.2-0.3 parts of foam stabilizer, 0.9-0.9 parts of foaming agent 1.2 parts, 1-1.3 parts of stabilizer, 0.6-0.9 parts of flame retardant, 0-5 parts of pigment.

[0073] The surface layer includes the following raw materials by weight: 48-65 parts of SG-3 type PVC resin, 23-32 parts of plasticizer, 10-13 parts of filler, 1.5-2 parts of stabilizer, 1.5-2 parts of flame retardant parts, 0-5 parts of pigmen...

Embodiment 1

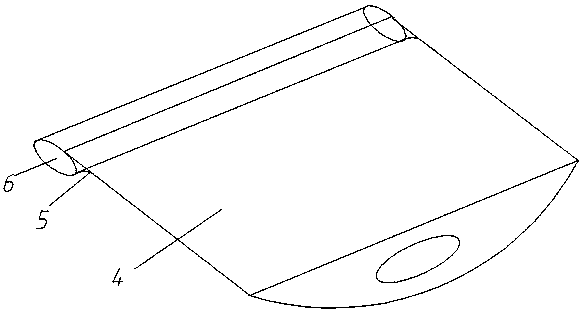

[0088] Prepare the raw materials required for the foaming layer and the surface layer according to the weight ratio, put them into a high-speed stirring pot and stir at high speed for 5 minutes to obtain the foaming layer mixed powder and the surface layer mixed powder, and the mixed powder is successively banburyed, The foam layer and surface layer are obtained by kneading, extrusion, and calendering. The foam layer and surface layer are placed on the base fabric layer in turn for lamination, and then the laminated semi-finished product is foamed and embossed, and finally the surface is treated with an environmental protection agent. Process and dry to obtain PVC leather, and further use the PVC leather without adhesive to make car blinds.

[0089] The raw materials of the foam layer formula include by weight: 44 parts of SG-5 type PVC resin, 22 parts of plasticizer, 27 parts of filler, 0.24 parts of foam stabilizer, 1 part of foaming agent, 1.1 parts of stabilizer, pigment 4...

Embodiment 2

[0095] Prepare PVC leather with the method described in application example 1, difference is:

[0096] The raw materials of the foam layer formula include by weight: 50 parts of SG-5 type PVC resin, 20 parts of plasticizer, 20 parts of filler, 0.3 part of foam stabilizer, 1.2 parts of foaming agent, 1.3 parts of stabilizer, pigment 4 parts, 0.9 parts of flame retardant.

[0097] The surface layer formulation raw materials include by weight: 65 parts of SG-3 type PVC resin, 23 parts of plasticizer, 10 parts of filler, 1.5 parts of stabilizer, 0 part of pigment, and 1.6 parts of flame retardant.

[0098] The melting temperature of the surface layer is 162°C, and the melting temperature of the foam layer is 147°C.

[0099]The PVC leather has good mechanical properties and high flame retardancy. The flame retardancy rate is 35mm / min. After it is made into a car curtain, the VOC is low and the bonding effect is good. Applying a force of 10KG from the direction of pulling out the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com