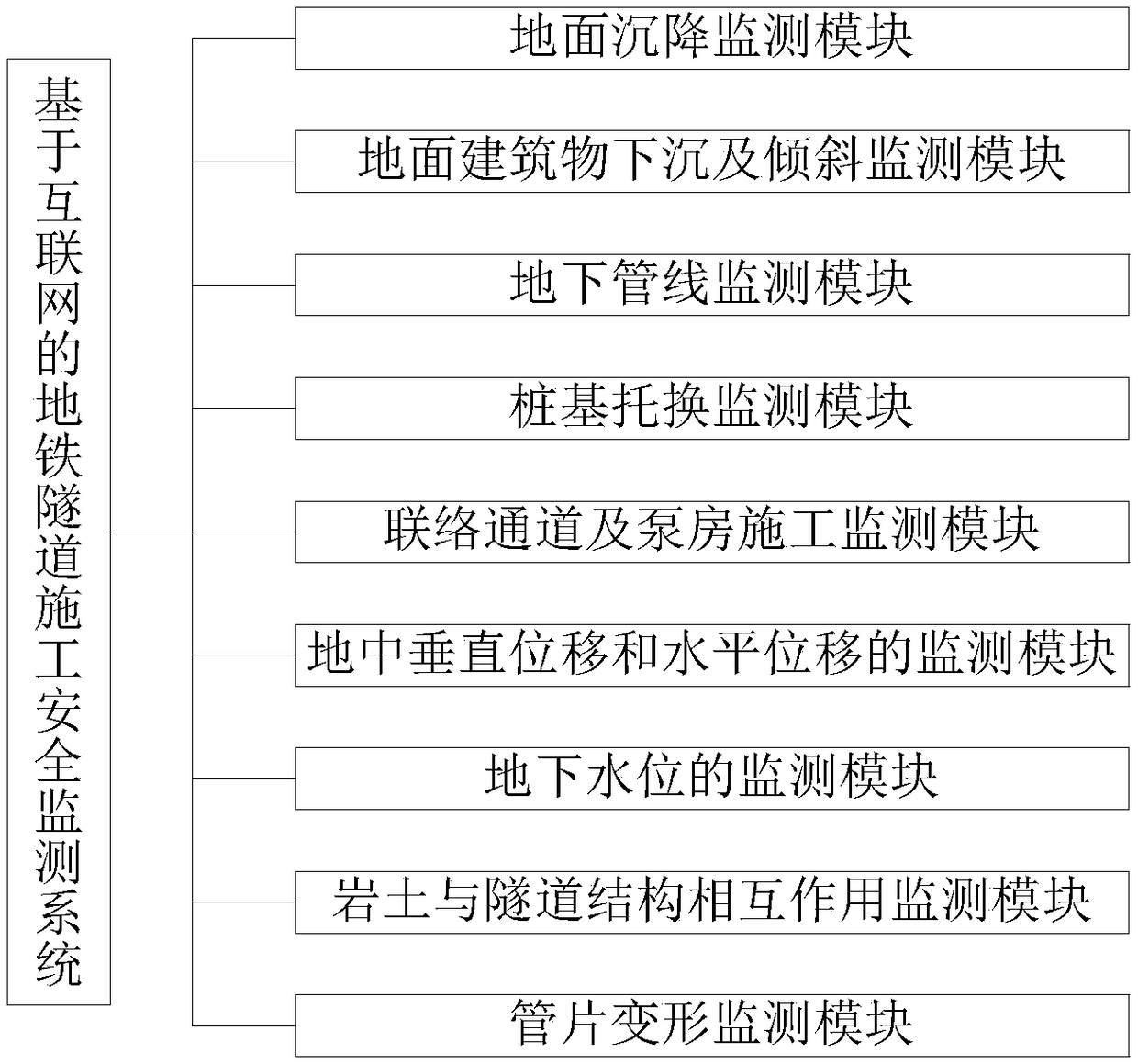

Internet-based subway tunnel construction safety monitoring system

A technology for tunnel construction and safety monitoring, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of waste of monitoring costs, many monitoring components, low monitoring performance and accuracy, to meet monitoring performance and accuracy, and reduce detection. components, the effect of reducing the detection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

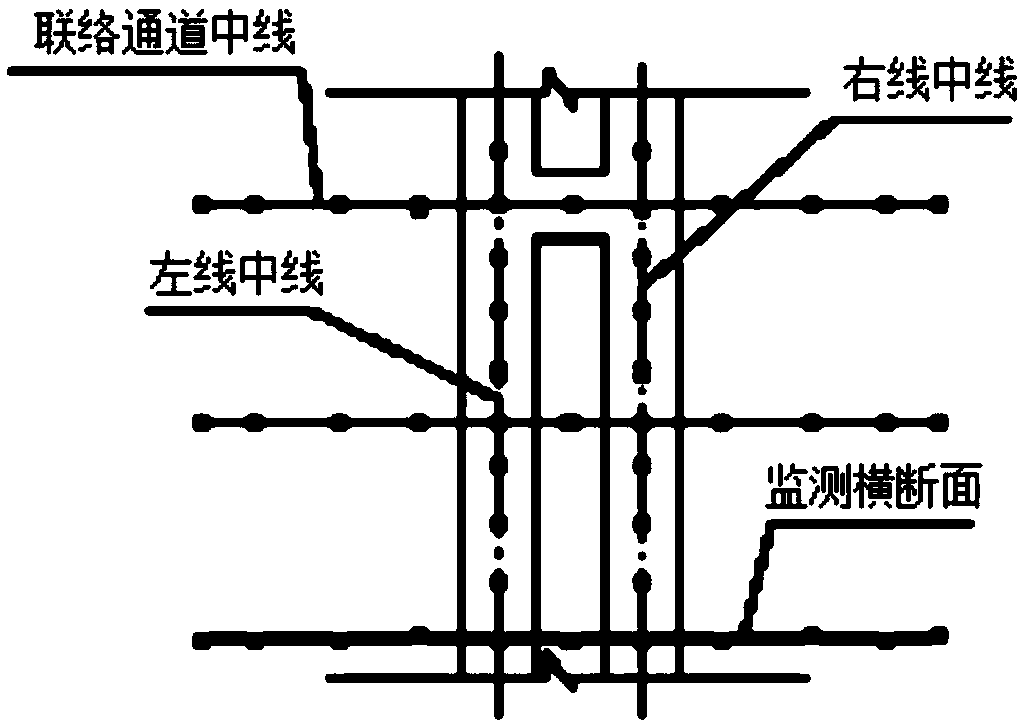

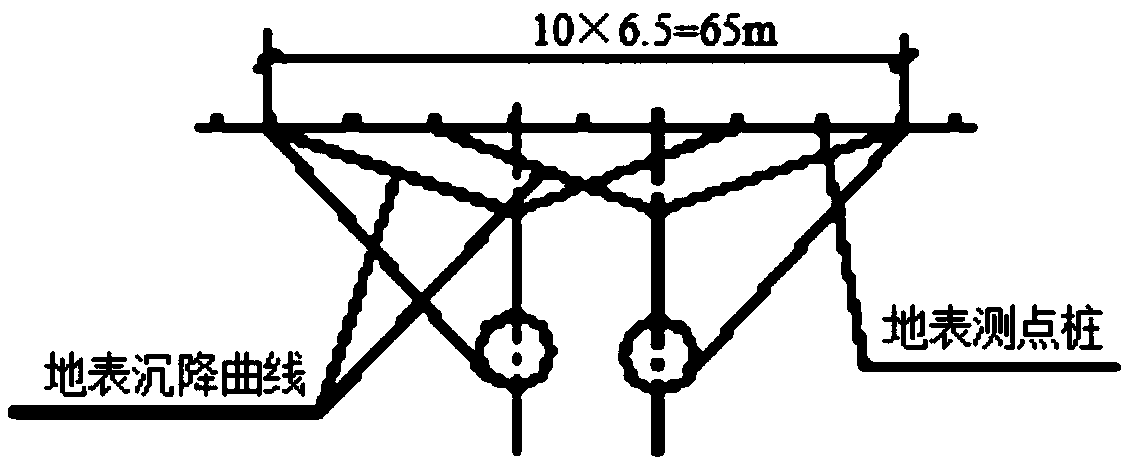

[0066] Example 1, Ground subsidence monitoring

[0067] The scope of the front 10m and the rear 20m of the shield machine nose is observed once a day in the morning and evening, and progresses with the construction progress. Each monitoring is guaranteed to partially overlap with the last observation point for comparison. Monitoring points outside the range shall be observed once a week until stable. When the settlement or uplift exceeds the specified limit (-30 / +10mm) or the change is abnormal, increase the monitoring frequency and detection range, organize timely analysis of the cause of abnormal deformation, and take corresponding measures to control the deformation. High-precision instruments such as NA2002 automatic electronic level and indium steel ruler are used to monitor surface settlement.

Embodiment 2

[0068] Example 2, Ground building monitoring

[0069] Settlement monitoring of buildings within 10m and 20m behind the nose of the shield machine is carried out, once a day in the morning and evening, and once a week after the shield machine passes through the building, until it is stable. For dangerous buildings and buildings with more than four floors, the inclination measurement must be carried out while the settlement is monitored, and cracks must be monitored for buildings with cracks. Use SOKA total station, NA2002 automatic electronic level and indium steel ruler for high-precision monitoring. For important buildings, automatic recorders and finishing devices are used.

Embodiment 3

[0070] Example 3: Underground pipeline monitoring

[0071] Settlement detection of underground pipelines within 10m before and 20m behind the head of the shield machine is carried out, once a day in the morning and evening, and once a week after the past, until stable. The allowable deformation value of important pipelines such as gas pipelines and water pipelines will be confirmed in the pipeline survey after winning the bid. The monitoring of these pipelines should be strengthened. Use SOKA total station, NA2002 automatic electronic level and indium steel ruler for high-precision monitoring. When the maximum displacement value exceeds the maximum warning value, the alarm should be reported in time, countermeasures should be studied, and the measurement frequency should be encrypted to prevent unexpected events until effective measures are taken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com