Slow-release fragrant gel composition and preparation method thereof

A technology of gel composition and aroma, applied in food science, application, tobacco, etc., can solve the problem of filter stick bursting, achieve good stability, and increase the amount of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

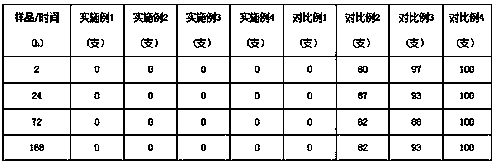

Examples

Embodiment 1

[0027] Embodiment 1: preparation orange flavor gel

[0028] The implementation steps of this embodiment are as follows:

[0029] A. Preparation of Polyethylene Glycol Mixture

[0030] Polyethylene glycol-1000, polyethylene glycol-1500, polyethylene glycol-4000, and polyethylene glycol-6000 were mixed according to a weight ratio of 15:25:30:12.5 to obtain mixture A;

[0031] B. Flavor pretreatment

[0032] At room temperature, sweet orange essential oil, propylene glycol fatty acid ester, and sodium stearic acid lactate were mixed according to a weight ratio of 4:1:1, and stirred evenly to obtain a stable colloidal dispersion, and mixture B was obtained;

[0033] C. Preparation of scented gel

[0034] Slowly add mixture B to mixture A and mix evenly, heat to dissolve completely in a water bath at 55°C with a stirring speed of 200 r / min, then add sodium carboxymethylcellulose, chitosan, pectin, Propylene glycol;

[0035] The raw material composition content is as follows: ...

Embodiment 2

[0038] The implementation steps of this embodiment are as follows:

[0039] A. Preparation of Polyethylene Glycol Mixture

[0040] Polyethylene glycol-1000, polyethylene glycol-1500, polyethylene glycol-4000, and polyethylene glycol-6000 were mixed according to the weight ratio of 15:25:25:10 to obtain mixture A;

[0041] B. Flavor pretreatment

[0042] At room temperature, sweet orange essential oil, sodium stearate, and sucrose fatty acid ester were mixed according to a weight ratio of 4:1:1, and stirred evenly to obtain a stable colloidal dispersion, and mixture B was obtained;

[0043] C. Preparation of scented gel

[0044] Mix mixture A and mixture B evenly, heat in a water bath at 55°C with a stirring speed of 200r / min until completely dissolved, then add sodium carboxymethylcellulose, seaweed fat, guar gum, and sorbitol;

[0045] The weight ratio of raw materials is as follows:

[0046] raw material

Embodiment 3

[0048] The implementation steps of this embodiment are as follows:

[0049] A. Preparation of Polyethylene Glycol Mixture

[0050] Polyethylene glycol-1000, polyethylene glycol-1500, polyethylene glycol-4000, and polyethylene glycol-6000 were mixed according to the weight ratio of 14:21:25:7 to obtain mixture A;

[0051] B. Flavor pretreatment

[0052] At room temperature, sweet orange essential oil, distilled monoglyceride, and soybean lecithin were mixed according to a weight ratio of 4:1:1, and stirred evenly to obtain a stable colloidal dispersion, and mixture B was obtained;

[0053] C. Preparation of scented gel

[0054] Mix mixture A and mixture B evenly, heat in a water bath at 55°C with a stirring speed of 200 r / min until completely dissolved, then add sodium polyacrylate, chitosan, starch derivatives, and glycerol;

[0055] The weight ratio of raw materials is as follows:

[0056] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com