An efficient and environmentally friendly machining waste treatment equipment

A technology of mechanical processing and processing equipment, which is applied in the direction of cleaning machinery, cleaning equipment, manual sweeping machinery, etc. It can solve the problems of inconvenient recycling, inconvenient cleaning of waste debris, and many impurities in waste debris, so as to achieve rich device functions and convenient cleaning. Recycling and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

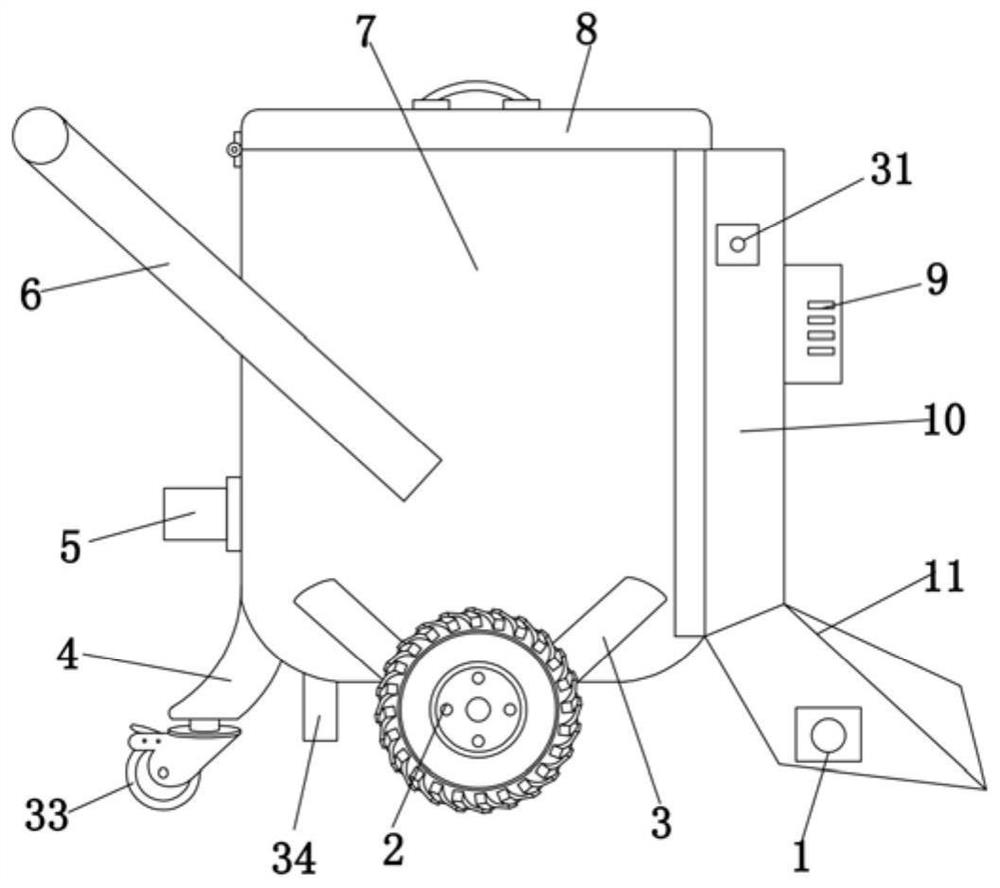

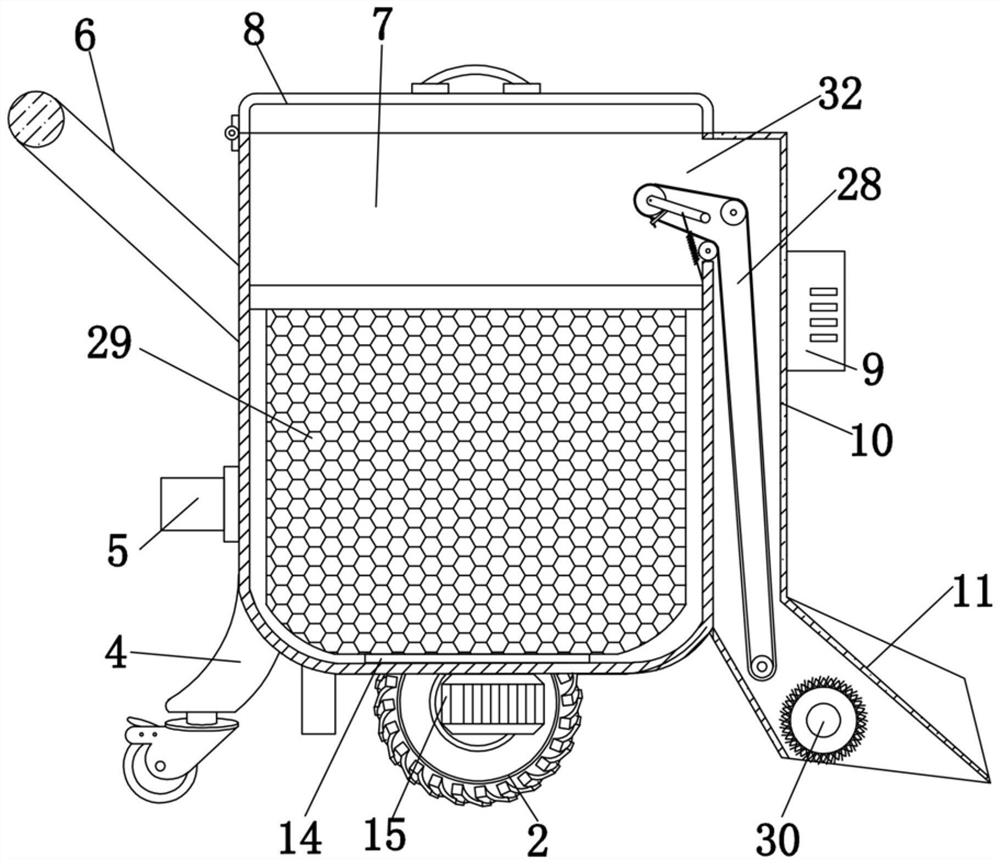

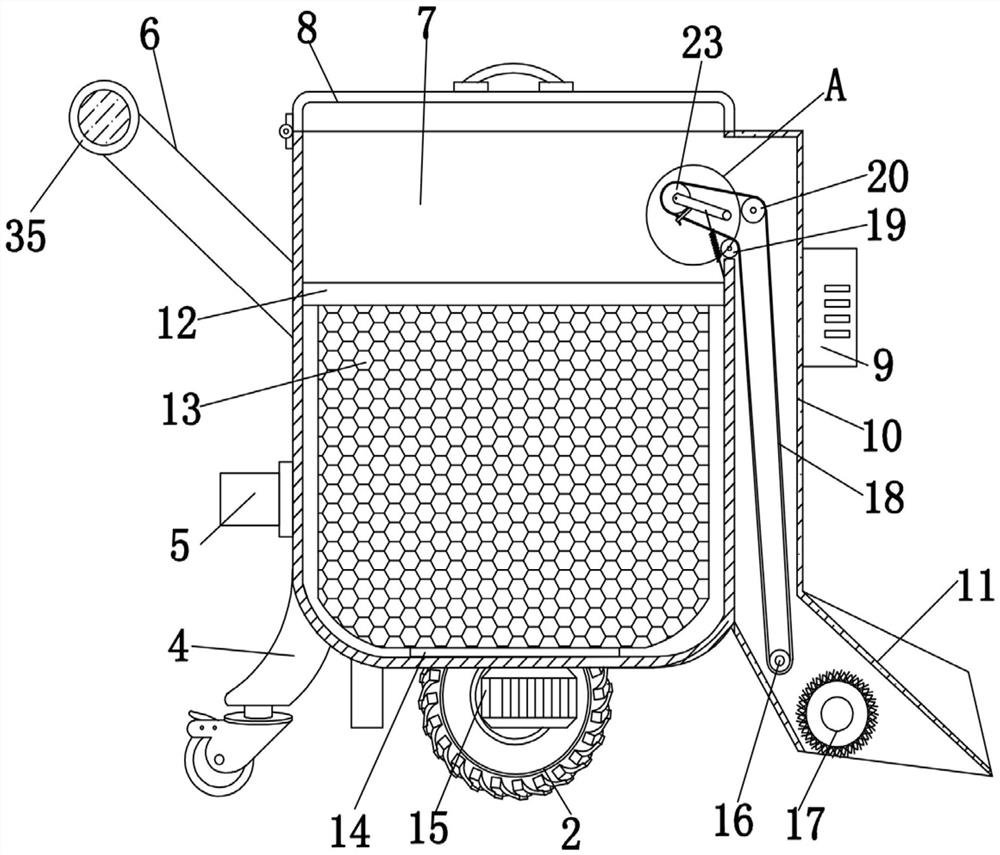

[0046] Example Figure 1-5 , A highly environmentally friendly mechanical machining waste treatment equipment, including metal cylinder 7, and the outer wall of the metal drum 7 is hinged in the outer wall 8, and the outer wall of the metal cylinder 7 is fixed by bolts 6, and the outer wall of the metal cylinder 7 The bracket 3 is welded, and the two stent 3 sides are active to be coupled with a wheel 2, and the metal cylinder 7 is facing away from the arm frame 6 side, and the suction mechanism includes a metal cover 10, and the metal cover 10 is welded. The suction bucket 11, the inner wall of the suction bucket 11 is provided with a cleaning mechanism 30, and the suction mechanism is fitted with the cleaning roller 17 to facilitate collecting waste to collect the waste on the machining ground, which is conducive to the preliminary screening of iron waste. It helps to increase the purity of the waste, the side wall of the metal cover 10 is fixed by the bolt, and the negative pre...

Embodiment 2

[0047] Example two reference Figure 1-5 The filter mechanism includes a first metal barrel 13, and the first metal barrel 13 side wall tip position is attached to the bearing ring 12, and the side wall of the bearing ring 12 and the inner wall of the metal cylinder 7 is close to the bottom of the feed hole. The first metal barrel 13 inner wall sleeve includes the second metal barrel 25, and the inner wall of the second metal barrel 25 welded to have a handle member 24, and the inner wall of the bottom end of the metal cylinder is fixed by the bolt, and there is a bearing turntable 14. And the top end of the bearing turntable 14 is fixed to the outer wall of the first metal barrel 13 by the bolt, and the intermediate position of the outer wall of the metal cylinder 7 is fixed by the bolt, and the third motor 15 output shaft passes through the bottom end of the metal tube 7. The inner wall and the first metal barrel 13 are fixed by bolt.

Embodiment 3

[0048] Example three reference Figure 1-5 The cleaning mechanism includes a cleaning roller 17, the cleaning roller 17 is attached to the inner wall of the suction bucket 11, and the sidewall of the suction strip 11 is fixed by the bolt, and the first motor 1 output shaft passes through the suction bucket 11 side outer wall The end of the cleaning roller 17 is fixed by a bolt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com