Method for preparing monoatomic catalysts

A catalyst and atom technology, applied in the field of materials science and engineering, can solve the problems of mismatching the size of single-atom catalysts and reaction substrates, lack of electronic or spatial synergy, and small size of a single metal atom, and meet the requirements of experimental diversification. , to achieve accurate and controllable, reduce the effect of experimental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

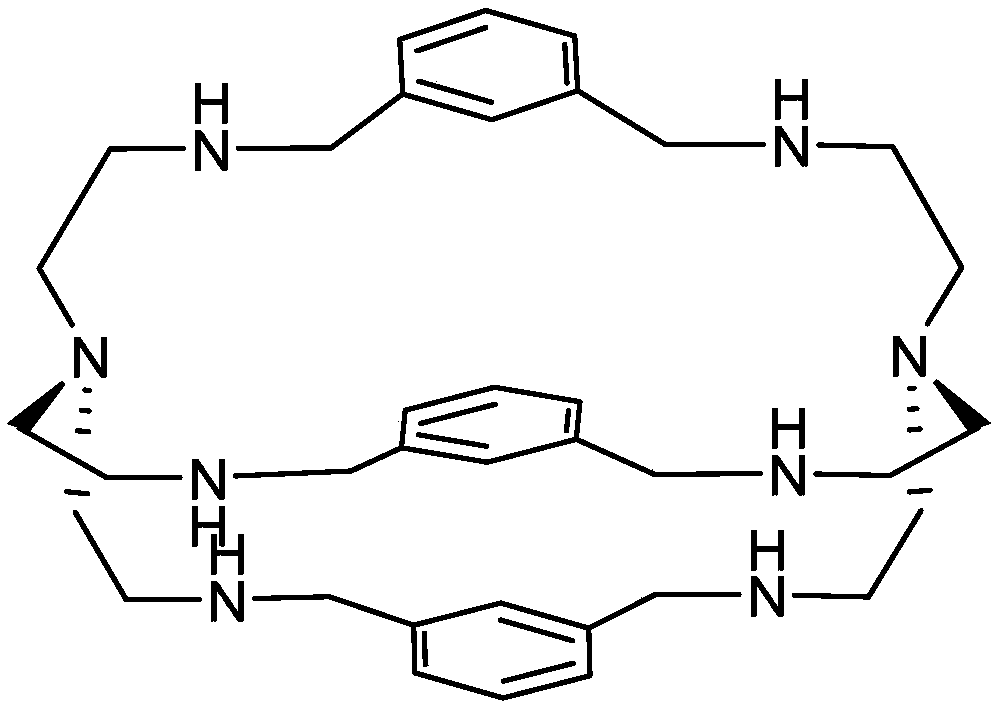

[0033] Preparation of organic cryptand molecules: Weigh an appropriate amount of tris(2-aminoethyl)amine and m-phthalaldehyde into a round-bottomed flask filled with acetonitrile solution, stir until completely dissolved and mix, and continue stirring for a certain period of time. Filtration and washing yielded an intermediate product. Finally, through reduction, extraction, drying and other steps to obtain organic cryptand molecular products (such as figure 1 ).

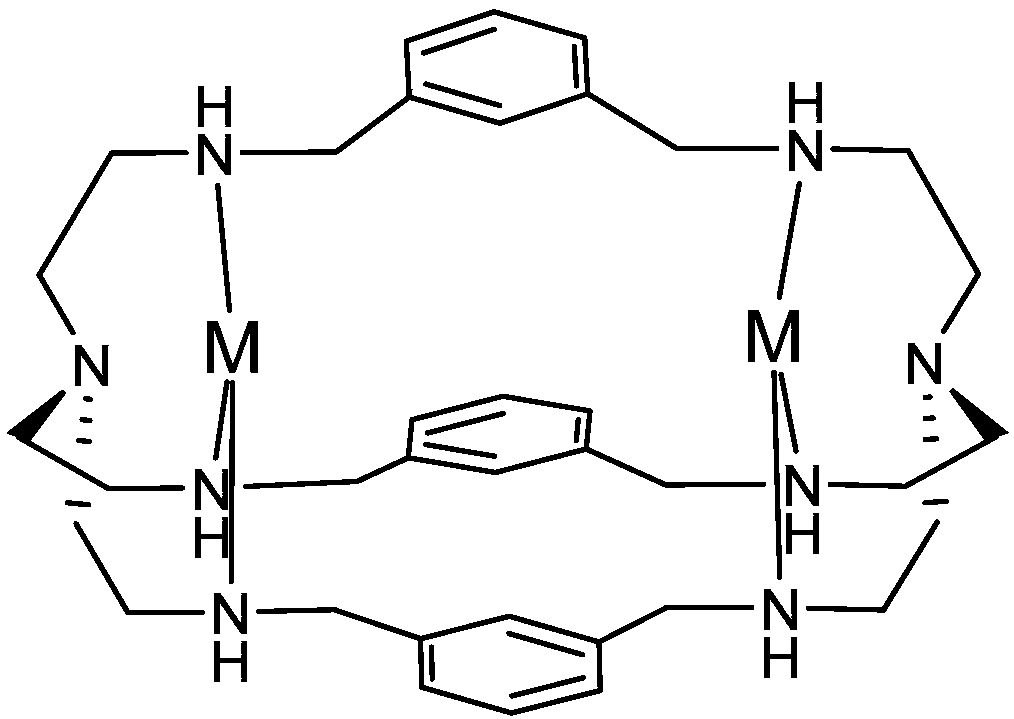

[0034] transition metal precursors (such as figure 2 ) preparation: Weigh an appropriate amount of organic cryptand molecules and copper perchlorate hexahydrate and dissolve them in acetonitrile solution, mix and stir for a certain period of time after being completely dissolved, and obtain copper precursor products after filtering, washing and drying.

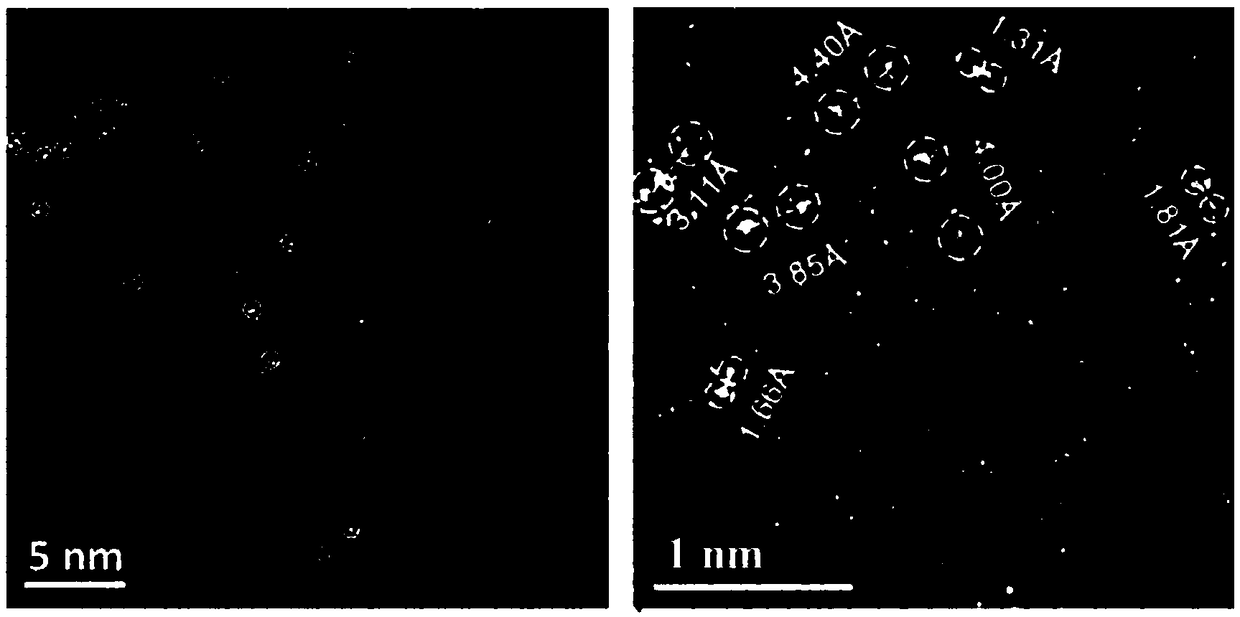

[0035] Weigh 0.02g of the mixture of copper precursor and 1g of carbon black and add it into a 50mL agate ball mill jar, put some agate balls in the jar, put the...

Embodiment 2

[0037] Preparation of organic cryptand molecules: Weigh an appropriate amount of tris(2-aminoethyl)amine and m-phthalaldehyde into a round-bottomed flask filled with acetonitrile solution, stir until completely dissolved, then mix, and continue stirring for a certain period of time. Filtration and washing yielded an intermediate product. Finally, the organic ligand molecular product is obtained through reduction, extraction, drying and other steps.

[0038] Preparation of transition metal precursors: Weigh appropriate amount of organic ligand molecules and copper perchlorate hexahydrate and dissolve them in acetonitrile solution, mix and stir for a certain period of time after complete dissolution, and obtain copper precursor products after filtering, washing and drying.

[0039] Weigh 0.06g of the mixture of copper precursor and 3 g of carbon black and add it into a 100mL agate ball mill jar, put a number of agate balls in the jar, put the agate ball mill jar into the planeta...

Embodiment 3

[0041] Preparation of organic cryptand molecules: Weigh an appropriate amount of tris(2-aminoethyl)amine and m-phthalaldehyde into a round-bottomed flask filled with acetonitrile solution, stir until completely dissolved, then mix, and continue stirring for a certain period of time. Filtration and washing yielded an intermediate product. Finally, the organic ligand molecular product is obtained through reduction, extraction, drying and other steps.

[0042] Preparation of transition metal precursors: Weigh appropriate amount of organic ligand molecules and copper perchlorate hexahydrate and dissolve them in acetonitrile solution, mix and stir for a certain period of time after complete dissolution, and obtain copper precursor products after filtering, washing and drying.

[0043] Weigh 0.2g of the mixture of copper precursor and 10g of carbon black and add it into a 250mL agate ball mill jar, put some agate balls in the jar, put the agate ball mill jar into the planetary ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com