A two-dimensional channel structure and its preparation method

A channel structure and channel technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems such as difficult to fine-tune the spacing between layers, large fluctuation deviation, and difficult positive surface charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

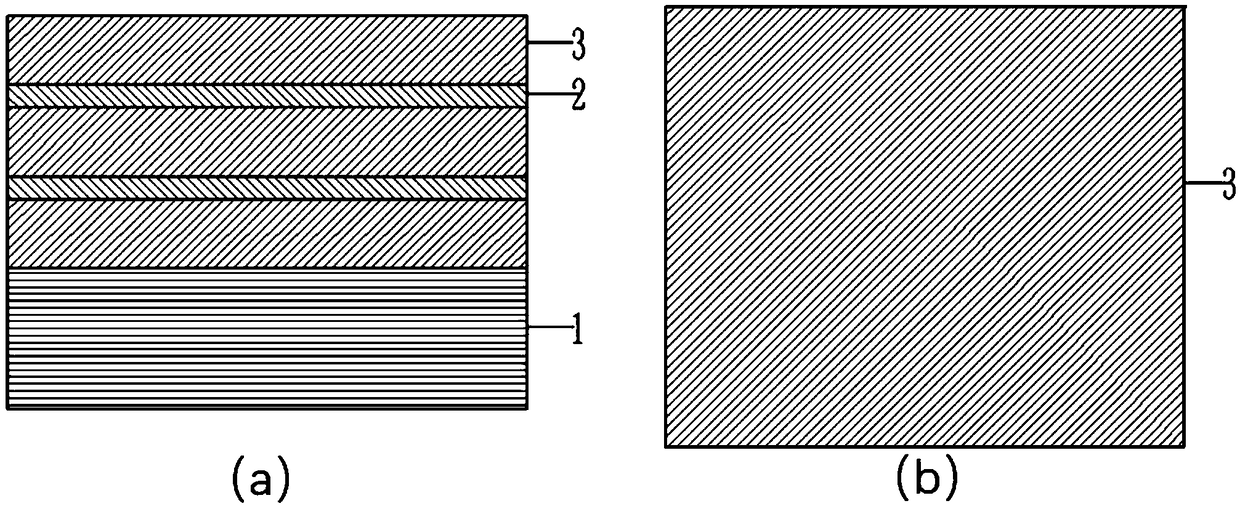

Embodiment 1

[0061] In this embodiment, a two-layer rectangular two-dimensional channel structure is prepared, and the layer structure of a single-layer two-dimensional channel is a long rectangle of 800nm*600nm, with a thickness of 10nm and a size of 800nm*10nm at both ends of the opening. Take Al 2 o 3 As the substrate, the isolation layer AlN and the sacrificial layer GaN are grown by the MBE method. The growth process is carried out in an ultra-high vacuum growth chamber. The high-purity (7N) metal source is generated by a K-Cell source furnace, and the nitrogen source is a radio frequency plasma nitrogen source. , the growth process was monitored in situ by reflection high-energy electron diffractometer RHEED, and SiO was prepared by chemical vapor deposition CVD 2 The scaffolds were etched using photolithography.

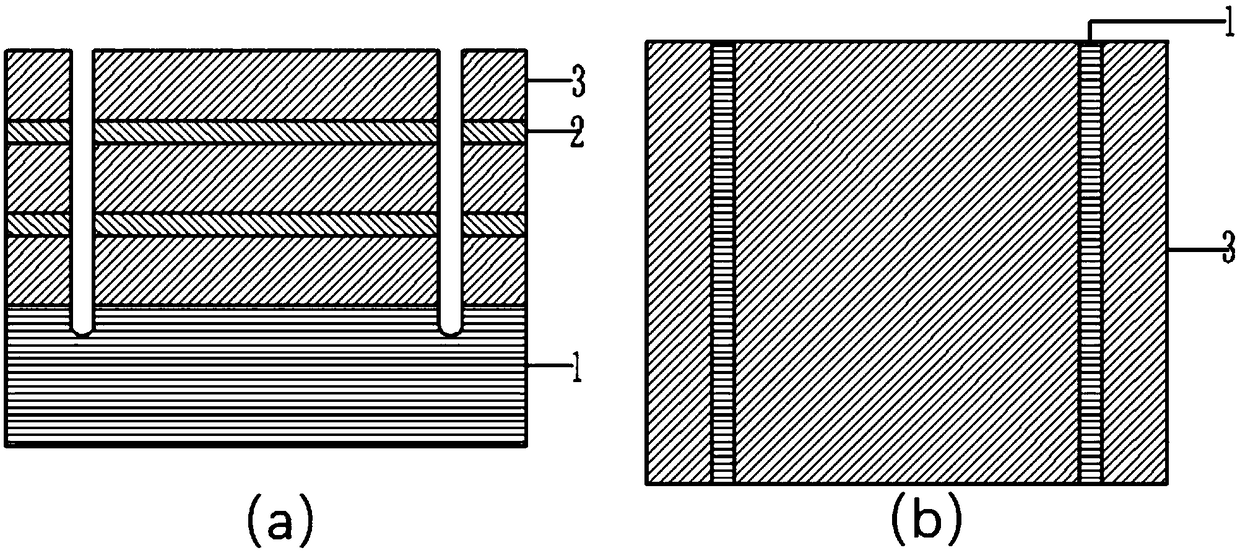

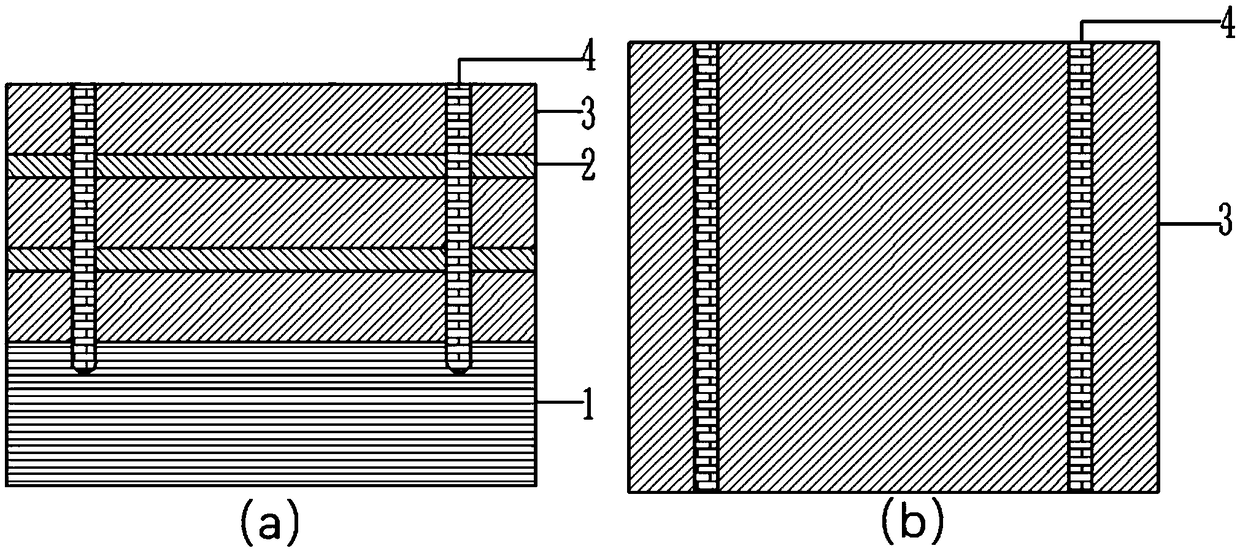

[0062] The preparation method of the two-dimensional channel structure of this embodiment includes the following steps:

[0063] 1) Provide Al 2 o 3 As the substrate ...

Embodiment 2

[0073] In this embodiment, a two-layer two-dimensional channel structure is prepared, the shape of the channel in each layer is a trident shape, and the layer structure of the two-dimensional channel is Image 6 shown. The growth steps are basically the same as in Embodiment 1, the difference is that in step 4) only the pattern is kept, and the rest are etched away. After this step, the two-dimensional channel template is as follows: Figure 7 Shown; Step 6) Only engrave the middle engraved port Figure 8 Groove 31 in, etch to Al 2 o 3 layer, after this step the two-dimensional channel template such as Figure 8 shown.

[0074] In addition to the advantages of Embodiment 1, the double-layer three-fork two-dimensional channel structure prepared by the above method is characterized in that fluid can be injected from two inlets and flow out from the third channel outlet. This design can be used to realize the synthesis of biopharmaceuticals, two channels are raw material inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com