Laser hole-making device based on direct-current electric field and axial magnetic field

A technology of axial magnetic field and DC electric field, applied in the direction of laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems that affect the formation of microholes, the process of hole making cannot be carried out, and reduce the utilization rate of laser, so as to achieve enhanced stability, The effect of improving the quality of hole making and improving the efficiency of hole making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

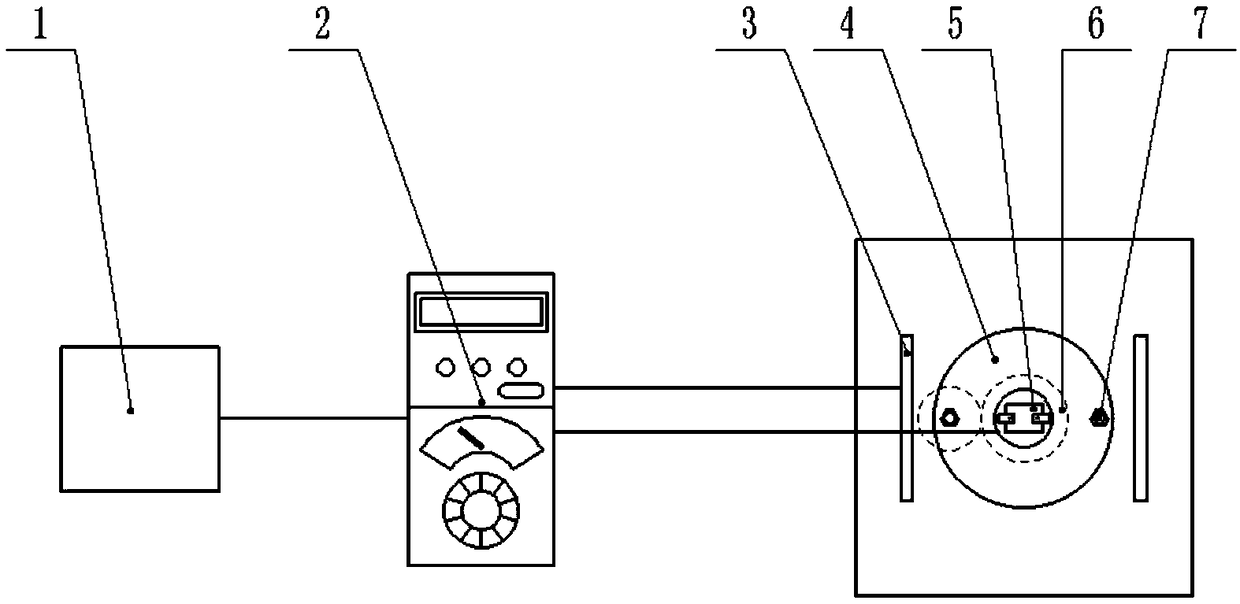

[0031] like figure 1 As shown, a laser drilling device based on a DC electric field and an axial magnetic field according to the present invention includes a power supply 1, a control system 2, an electric field generating unit 3, a magnetic field generating unit 4, a workpiece clamping unit 5, and a workpiece rotating unit 6. Lifting device 7 and laser generating unit.

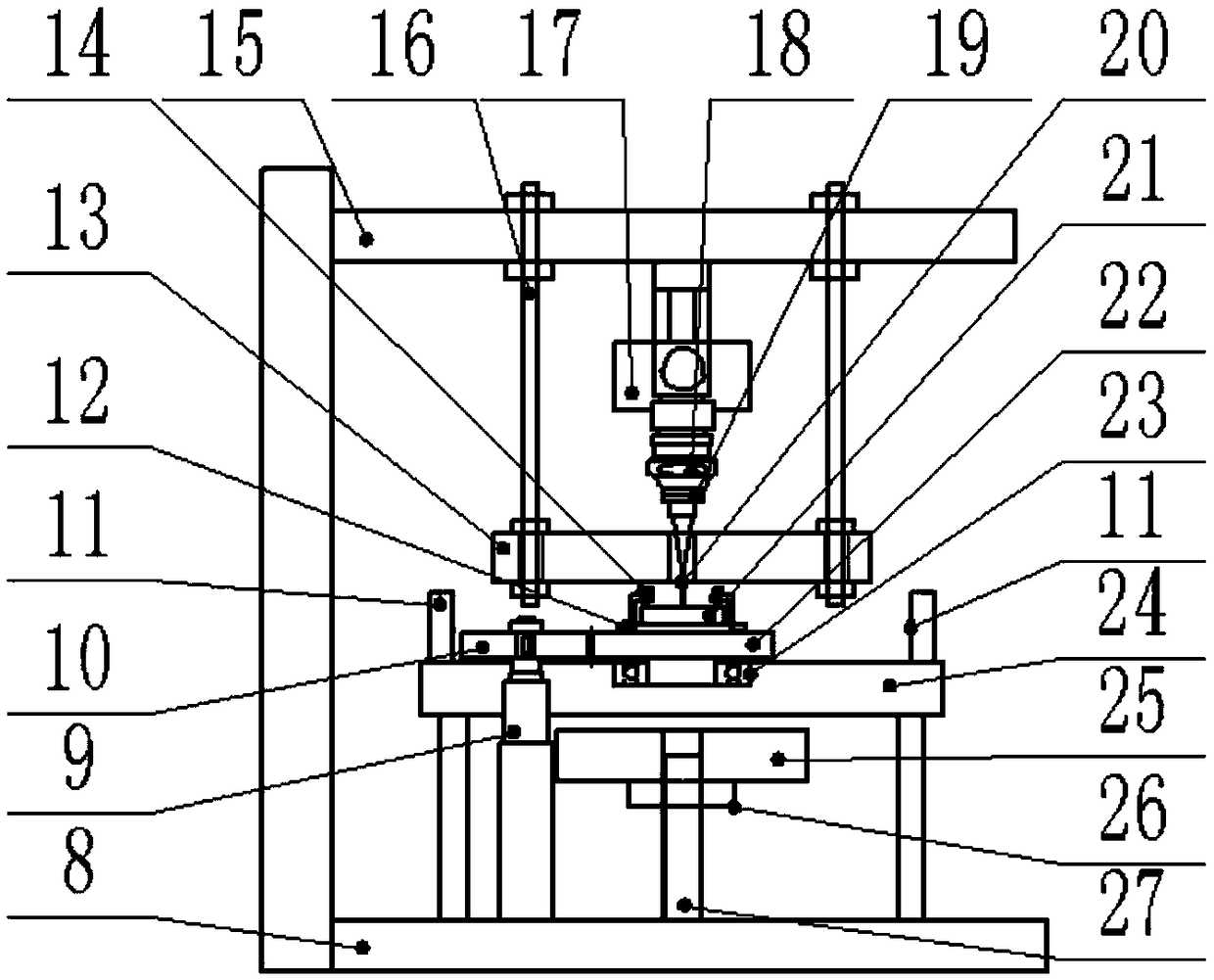

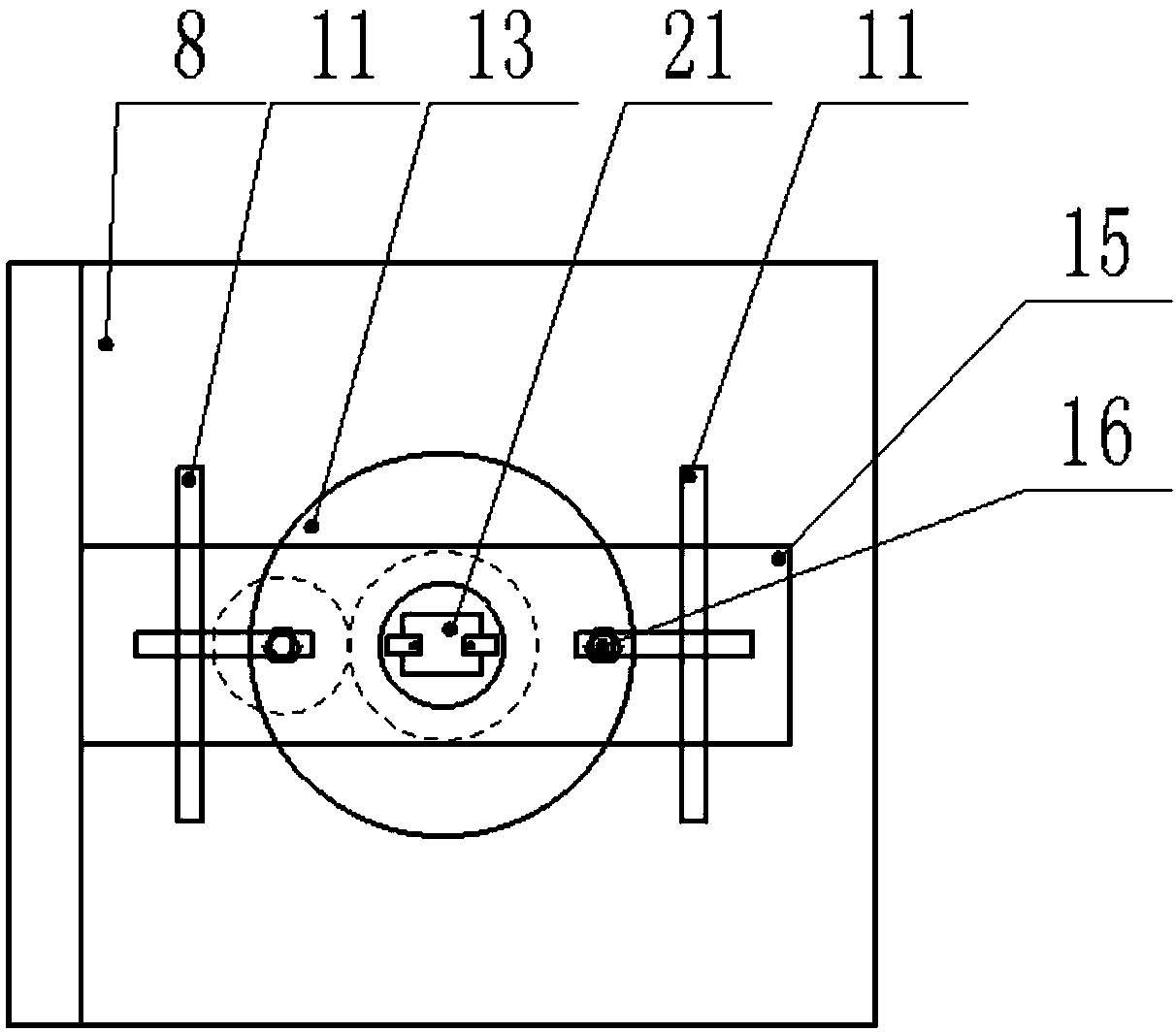

[0032] like figure 2 As shown, the electric field generating unit 3 includes a support 24 and two electrode plates 11 mounted on the support 24, the support 24 is installed on the machine tool base 8, and the two electrode plates 11 are electrically connected to the control system 2, The control system 2 is electrically connected with the power source 1, and can control the electrode plate 11 to gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com