A special mold and production process for concrete electric poles with convenient construction

A production process and concrete technology, applied in the direction of molds, etc., can solve the problems of adjustment, can not save transportation space, affect the erection efficiency of electric poles, etc., and achieve the effect of saving costs, improving the efficiency of opening holes, and accelerating production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

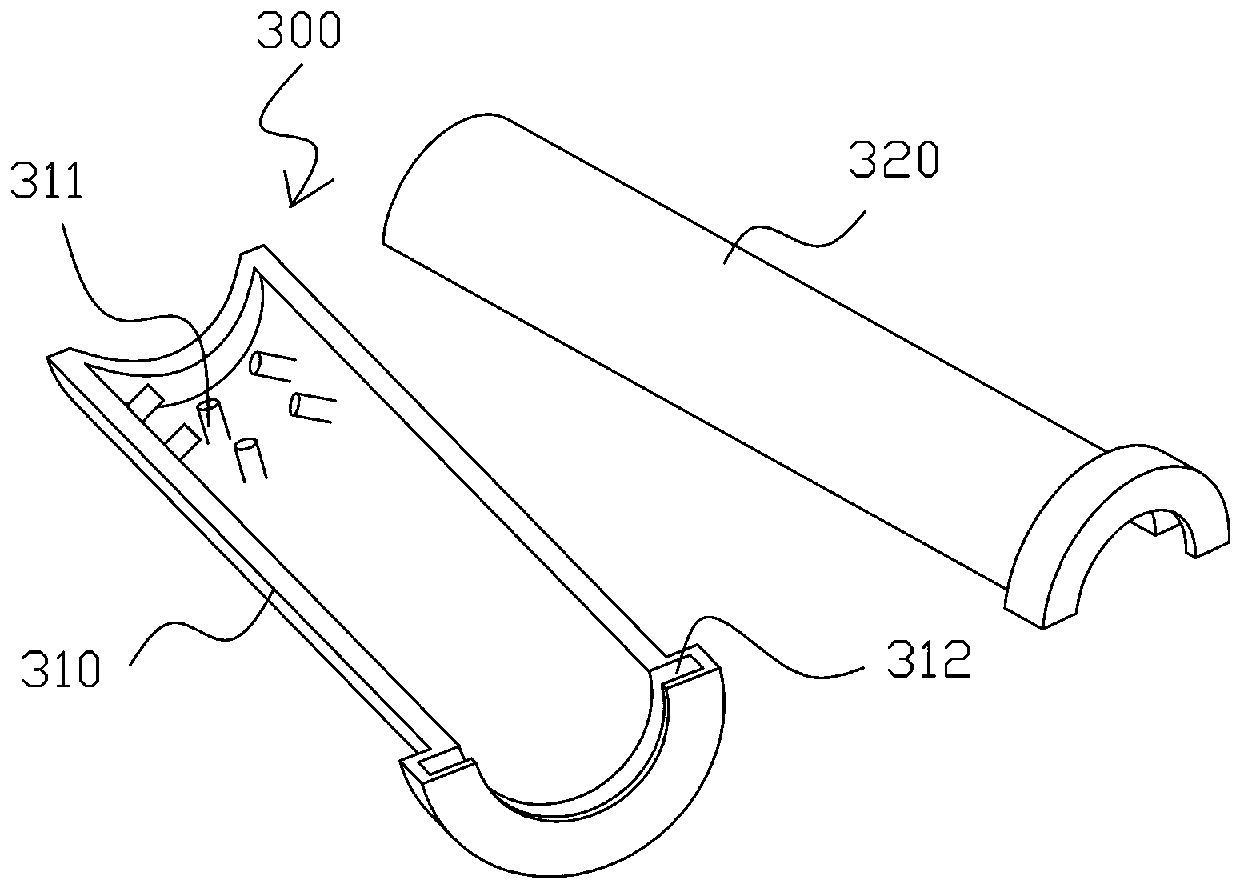

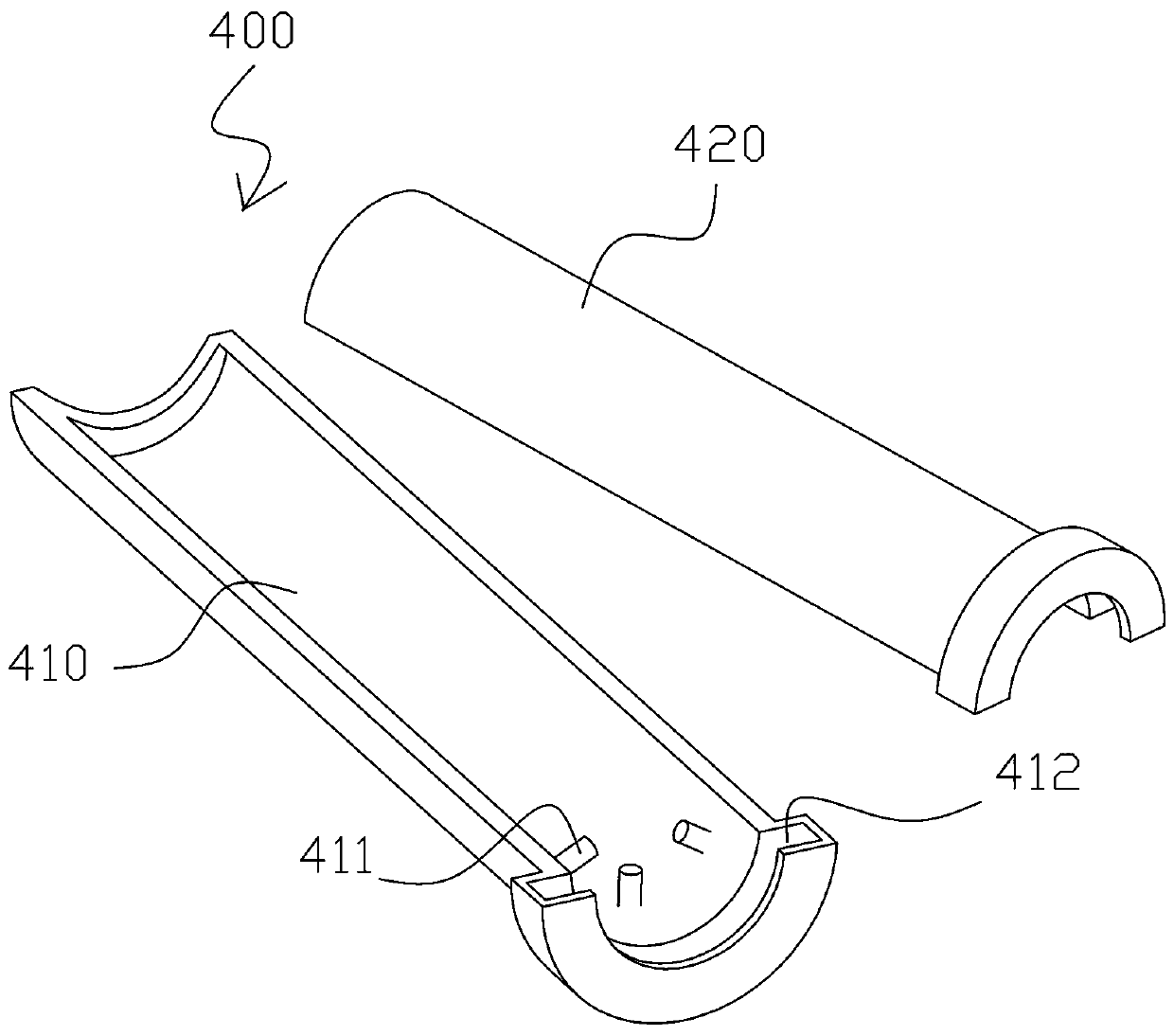

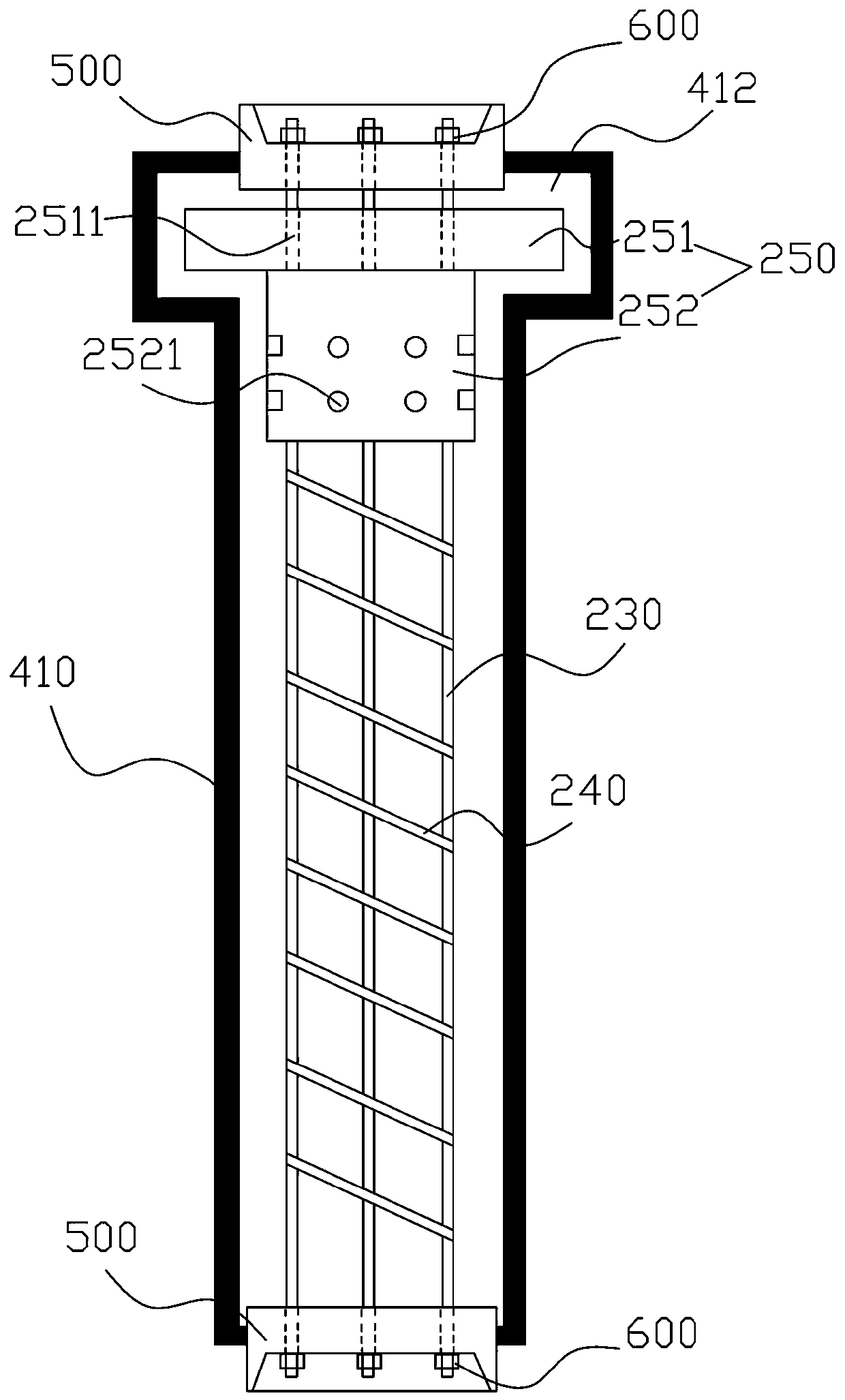

[0076] Such as figure 1 , figure 2 As shown, this embodiment provides a special mold for concrete poles that is convenient for construction, including an upper pole steel mold 300 and a lower pole steel mold 400; the upper pole steel mold 300 includes a coaxially arranged upper pole first half membrane 310 and the second half-membrane 320 of the upper rod, the upper end of the first half-membrane 310 of the upper rod and the upper end of the second half-membrane 320 of the upper rod are formed with an upper rod concave cavity 312 protruding outwards in a semi-circular shape, the upper rod The inner surface of the lower end of the first half-membrane 310 and the inner surface of the lower end of the second half-membrane 320 of the upper rod are equally spaced along the length direction to form multiple groups of protruding column groups, and each of the protruding column groups includes several radially protruding coils. The upper rod protruding pillars 311 distributed at int...

Embodiment 2

[0084] This embodiment provides a production process for a convenient concrete pole, which is produced using the mold described in Embodiment 1, including the following steps:

[0085] S1: Use the upper rod production line to prepare the upper rod through the upper rod steel mold 300; on the upper rod production line, select the corresponding upper rod steel mold 300 according to the size and taper of the proposed upper rod to prepare the upper rod;

[0086] S2: Using the lower rod production line to prepare the lower rod with a hollow inner cavity through the lower rod steel mold 400; on the lower rod production line, select the corresponding lower rod steel mold 400 according to the size and taper of the proposed lower rod to prepare the lower rod;

[0087] S3: Using an assembly production line to place the upper pole into the hollow inner cavity of the lower pole to obtain a finished electric pole.

[0088] In the above design, by dividing the production preparation of the ...

Embodiment 3

[0091] The difference between this embodiment and embodiment 2 is that the step S2 includes the following steps:

[0092] S21: Prepare and fix the lower rod steel skeleton in the first half membrane 410 of the lower rod;

[0093] S22: Pour concrete; put a preset amount of concrete slurry into the first half-membrane 410 of the lower rod on which the reinforcement skeleton of the lower rod is fixed; specifically, use a feeding device to move along the lower rod at a certain speed The first half-membrane 410 moves in the length direction, while releasing the concrete slurry and inserting it into the first half-membrane 410 of the lower rod;

[0094] S23: 400 lower rod steel mold clamping;

[0095] S24: stretching and centrifugation;

[0096] S25: Curing; put the lower rod steel film 400 after centrifugation into the steam pool for steam curing according to a given process curve. The steam curing process includes four stages of static curing-heating-constant temperature-cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com