Plastic waste film extrusion device based on waste plastic secondary utilization technology

An extrusion device, waste plastic technology, applied in recycling technology, plastic recycling, mechanical material recycling, etc., can solve the problems of rising processing costs, inability to deal with impurities and unmelted plastic particles, equipment damage, etc., to reduce raw materials. cost, reduce plastic pollution and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

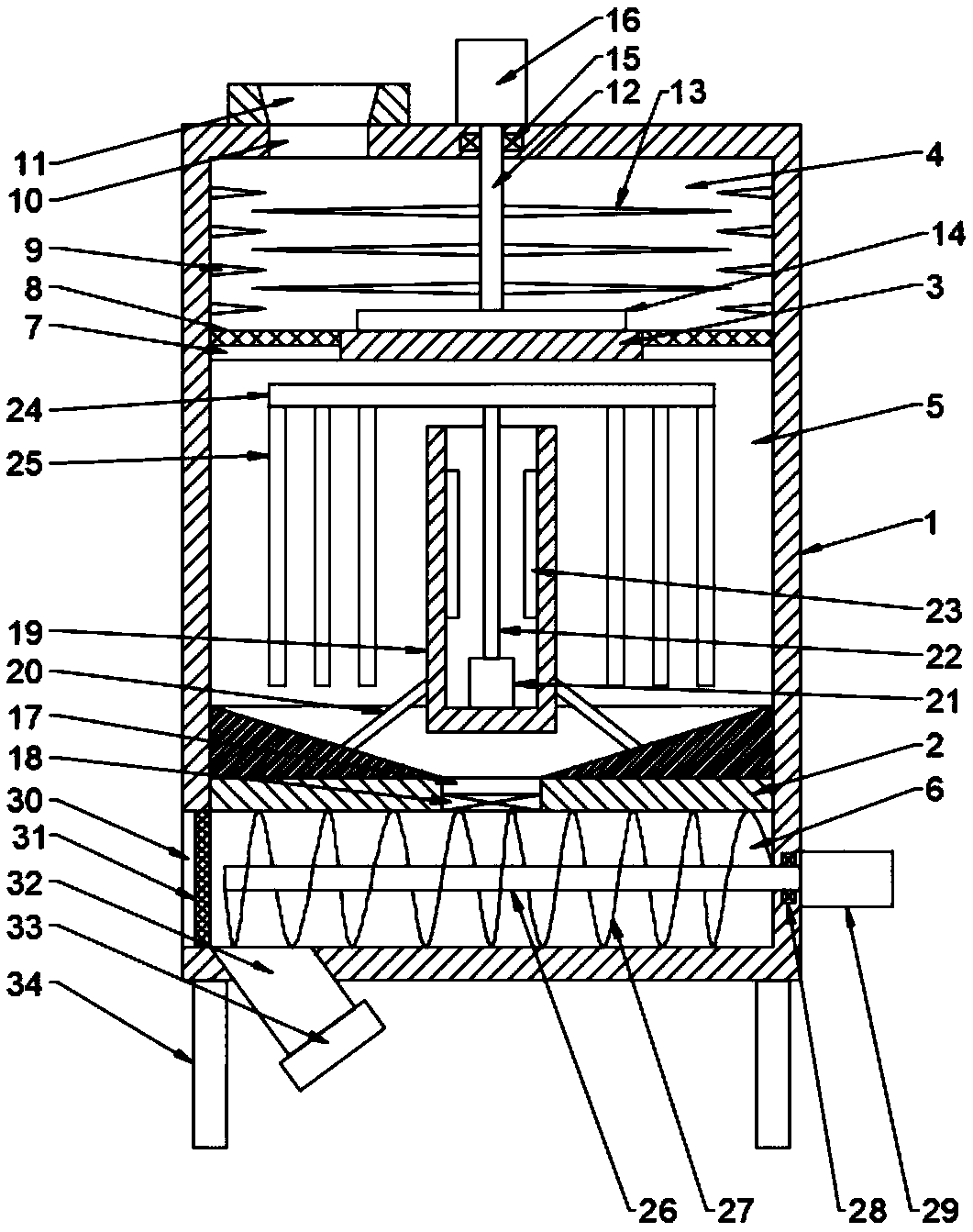

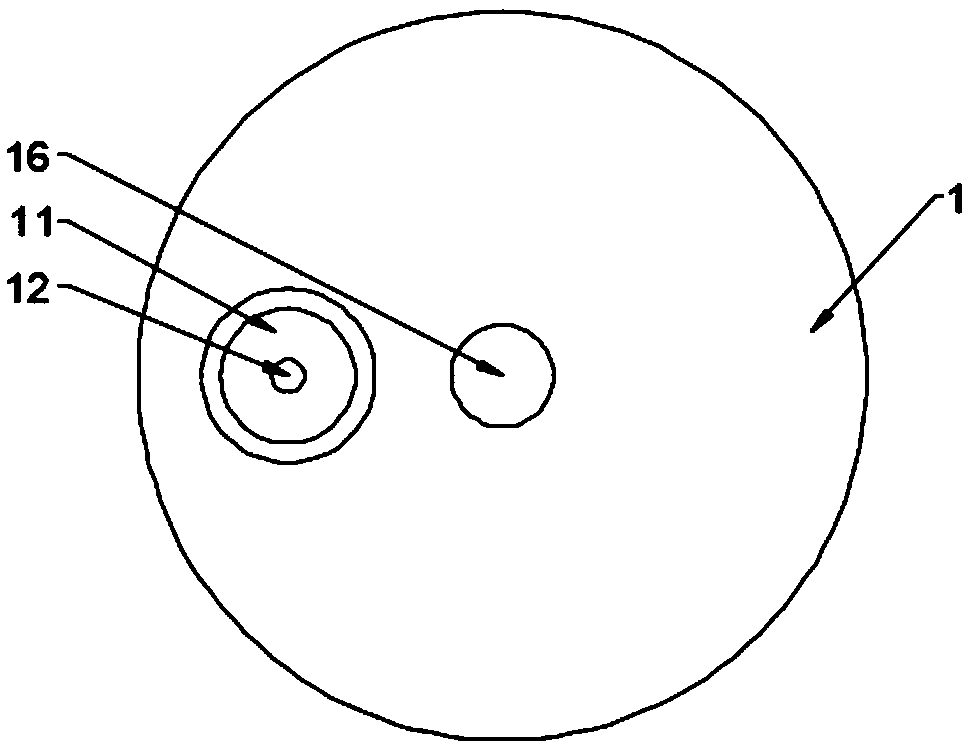

[0027] see Figure 1~3 , a plastic waste film extrusion device based on waste plastic secondary utilization technology, comprising a body 1, the upper and lower parts of the inner cavity of the body 1 are respectively provided with an upper partition 3 and a lower partition 2, and the upper partition 3 The inner cavity of the body 1 is divided into a crushing chamber 4, a mixing chamber 5 and a discharge chamber 6 from top to bottom with the lower partition plate 2, and a plurality of first communication holes 7 are evenly provided on the edge of the upper partition plate 3, The first communication hole 7 is provided with a filter screen 8, the center of the lower partition 2 is provided with a second communication hole 17, and the second communication hole 17 is provided with a control valve 18. One side of the top is connected to the feeding hole 10, and the top of the feeding hole 10 is connected to the feeding hopper 11. The material is added through the feeding hopper 11,...

Embodiment 2

[0030] This embodiment is a further elaboration on the basis of Embodiment 1. The bottom wall of the inner cavity of the mixing chamber 5 is provided with a diversion bucket matched with the second communication hole 17, and the middle of the inner cavity of the mixing chamber 5 is provided with a heating Cylinder 19, the heating cylinder 19 is a cylindrical structure with an open top, the heating cylinder 19 is fixedly connected to the diversion bucket through the connecting rod 20, and the inner cavity side wall of the heating cylinder 19 is evenly provided with a number of electric heating devices 23 for heating The inner cavity bottom wall of the cylinder 19 is provided with a mixing motor 21, the motor shaft of the motor 21 is fixedly connected to the stirring rod 22, the axis of the stirring rod 22 coincides with the axis of the heating cylinder 19 and the axis of the body 1, and the stirring rod The top of 22 protrudes from the heating cylinder 19 and is fixedly connecte...

Embodiment 3

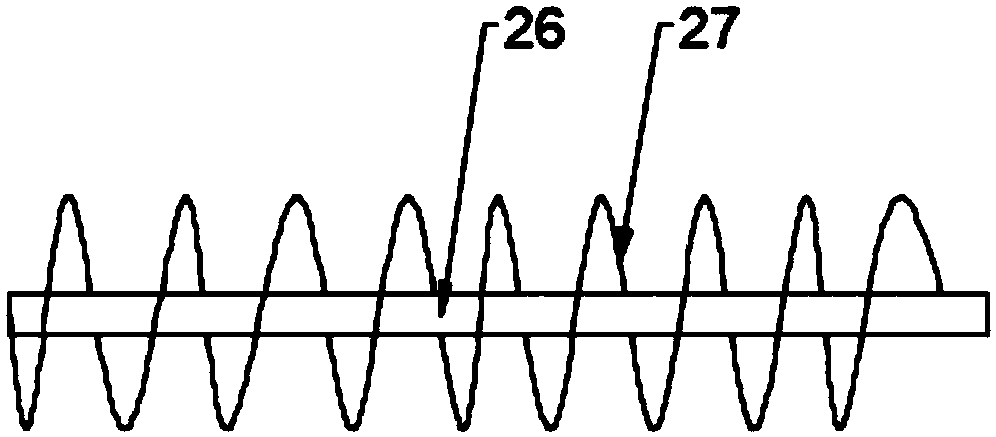

[0032] This embodiment is a further elaboration on the basis of Embodiment 1. The left end of the discharge chamber 6 is provided with a discharge hole 30, and a filter screen 31 is provided in the discharge hole 30. The discharge chamber 6 is provided with a push rod 26, the right end of the push rod 26 runs through the right end of the discharge chamber 6 and is fixedly connected to the motor shaft of the push motor 29, and the push motor 29 is fixedly connected to the body 1 Above, the outer circular surface of the push rod 26 is provided with a push leaf 27 matched with the discharge hole 30, and the left side of the bottom wall of the inner cavity of the discharge chamber 6 is connected with a filter mesh 31. A slag discharge pipe 32, the slag discharge pipe 32 is installed obliquely, the other end of the slag discharge pipe 32 is covered with a sealing cover 33, and a number of legs 34 are evenly provided on the edge of the bottom surface of the body 1, and the stirred ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com