Plastic film and a courier bag

A technology for plastic films and raw materials, applied in the field of plastic products, can solve the problems of non-degradability and natural environment hazards, and achieve the effect of reduced thickness and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

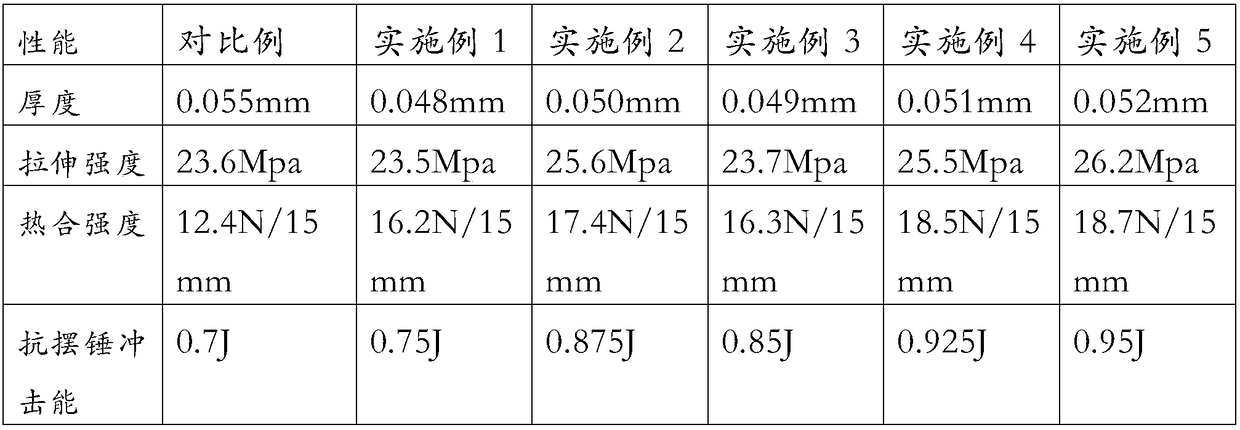

Examples

Embodiment 1

[0026] Weigh raw materials according to the following proportions:

[0027] The raw materials of the upper layer include the following substances in percentage by weight:

[0028] Linear Low Density Polyethylene 40.00%, Bimodal Polyethylene 50.00% and Metallocene 10.00%.

[0029] The raw materials of the middle layer include the following substances in percentage by weight:

[0030] Linear low density polyethylene 35%, high density polyethylene HDPE 20%, metallocene 25% and white masterbatch 20%.

[0031] The raw materials of the bottom layer include the following substances in percentage by weight:

[0032] Linear low density polyethylene with slip agent 73.5%, low density polyethylene thread with slip agent 10%, metallocene 15% and black masterbatch 1.5%.

[0033] The thickness ratio among the bottom layer, the middle layer and the upper layer is 3:4:3.

[0034] Preparation:

[0035] According to the above-mentioned thickness ratio, three layers of raw materials of the ...

Embodiment 2

[0038] Weigh raw materials according to the following proportions:

[0039] The raw materials of the upper layer include the following substances in percentage by weight:

[0040] Linear Low Density Polyethylene 40.00%, Bimodal Polyethylene 45.00% and Metallocene 15.00%.

[0041] The raw materials of the middle layer include the following substances in percentage by weight:

[0042] Linear low density polyethylene 35%, high density polyethylene HDPE 25%, metallocene 20% and white masterbatch 20%.

[0043] The raw materials of the bottom layer include the following substances in percentage by weight:

[0044] Linear low density polyethylene with slip agent 70%, low density polyethylene thread with slip agent 15%, metallocene 13.5% and gray masterbatch 1.5%.

[0045] The thickness ratio between the bottom layer, the middle layer and the upper layer is 3:4:3.

[0046] The preparation method is the same as in Example 1, except that the thickness of the courier bag in this exam...

Embodiment 3

[0048] Weigh raw materials according to the following proportions:

[0049] The raw materials of the upper layer include the following substances in percentage by weight:

[0050] Linear Low Density Polyethylene 35.00%, Bimodal Polyethylene 55.00% and Metallocene 10.00%.

[0051] The raw materials of the middle layer include the following substances in percentage by weight:

[0052] Linear low density polyethylene 30%, high density polyethylene HDPE 20%, metallocene 25% and white masterbatch 25%.

[0053] The raw materials of the bottom layer include the following substances in percentage by weight:

[0054] Linear low density polyethylene with slip agent 75%, low density polyethylene thread with slip agent 13%, metallocene 10% and black masterbatch 2%.

[0055] The thickness ratio between the bottom layer, the middle layer and the upper layer is 3:4:3.

[0056] The preparation method is the same as in Example 1, except that the thickness of the courier bag in this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com