Environmentally-friendly super-hydrophobic high weather-resistant wiper and preparation method thereof

A super-hydrophobic, high weather resistance, wiper technology, which is applied in vehicle maintenance, transportation and packaging, vehicle cleaning, etc., can solve the problems of reducing the service life of glass, endangering driving safety, and affecting the driver's sight, so as to improve the service life and prevent scratched effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

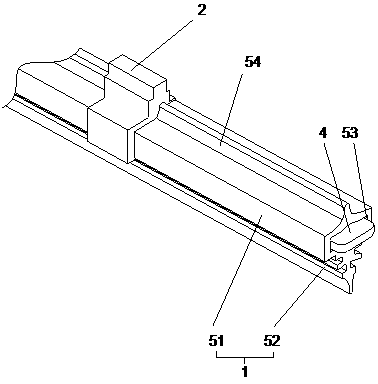

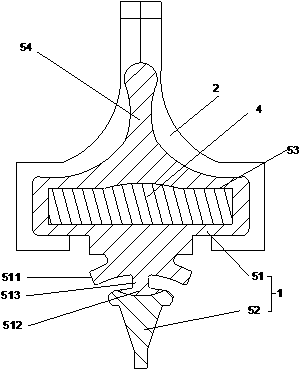

[0035]100 parts by weight of silica gel (German Wacker silica gel R401 / 50), 10 parts by weight of starch / cyclodextrin / polysulfide sulfone ternary compound, 5 parts by weight of nano-boron nitride, 5 parts by weight of nano-carbonized Silicon, 1 part by weight of nano-molybdenum disulfide, 1 part by weight of tetrapod-shaped zinc oxide whiskers, 1 part by weight of black graphite powder, 1 part by weight of Teflon and 1 part by weight of dimethyl silicone oil are placed in a high-speed In the mixer, the stirring rate is 1000 rpm, and after vacuuming and stirring at 120°C for 15 minutes, the hydrophobic silica gel material is obtained;

[0036] The hydrophobic silicone material is used as the material of the lower wiper part 52 and the rubber material (natural rubber, Manulife Rubber MFT-314) of the upper connection part 51 to form one body by solid-state hot pressing at 260 degrees to obtain a wiper strip;

[0037] The preparation method of the starch / cyclodextrin / polysulfide s...

Embodiment 2

[0040] 100 parts by weight of silica gel (German Wacker silica gel R401 / 50), 50 parts by weight of starch / cyclodextrin / polysulfide sulfone ternary compound, 10 parts by weight of nano-boron nitride, 20 parts by weight of nano-carbonized Silicon, 10 parts by weight of nano-molybdenum disulfide, 10 parts by weight of tetraacicular zinc oxide whiskers, 10 parts by weight of black graphite powder, 10 parts by weight of Teflon and 5 parts by weight of simethicone oil are placed in a high-speed In the mixer, the stirring rate is 1000 rpm, and after vacuuming and stirring at 120°C for 15 minutes, the hydrophobic silica gel material is obtained;

[0041] The hydrophobic silicone material is used as the material of the lower wiper part 52 and the rubber material (natural rubber, Manulife Rubber MFT-314) of the upper connection part 51 to form one body by solid-state hot pressing at 260 degrees to obtain a wiper strip;

[0042] The preparation method of the starch / cyclodextrin / polysulfi...

Embodiment 3

[0045] 100 parts by weight of silica gel (German Wacker silica gel R401 / 50), 48 parts by weight of starch / cyclodextrin / polysulfide sulfone ternary compound, 8 parts by weight of nano-boron nitride, 17 parts by weight of nano-carbide Silicon, 9 parts by weight of nano-molybdenum disulfide, 2 parts by weight of tetraacicular zinc oxide whiskers, 2 parts by weight of black graphite powder, 9 parts by weight of Teflon and 4 parts by weight of dimethyl silicone oil are put into the high-speed In the mixer, the stirring rate is 1000 rpm, and after vacuuming and stirring at 120°C for 15 minutes, the hydrophobic silica gel material is obtained;

[0046] The hydrophobic silicone material is used as the material of the lower wiper part 52 and the rubber material (natural rubber, Manulife Rubber MFT-314) of the upper connection part 51 to form one body by solid-state hot pressing at 260 degrees to obtain a wiper strip;

[0047] The preparation method of the starch / cyclodextrin / polysulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com