An activated carbon particle preparing device

A technology of activated carbon particles and preparation device, which is applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of large operation vibration, low output, high noise, etc., and achieve the effect of improving product molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

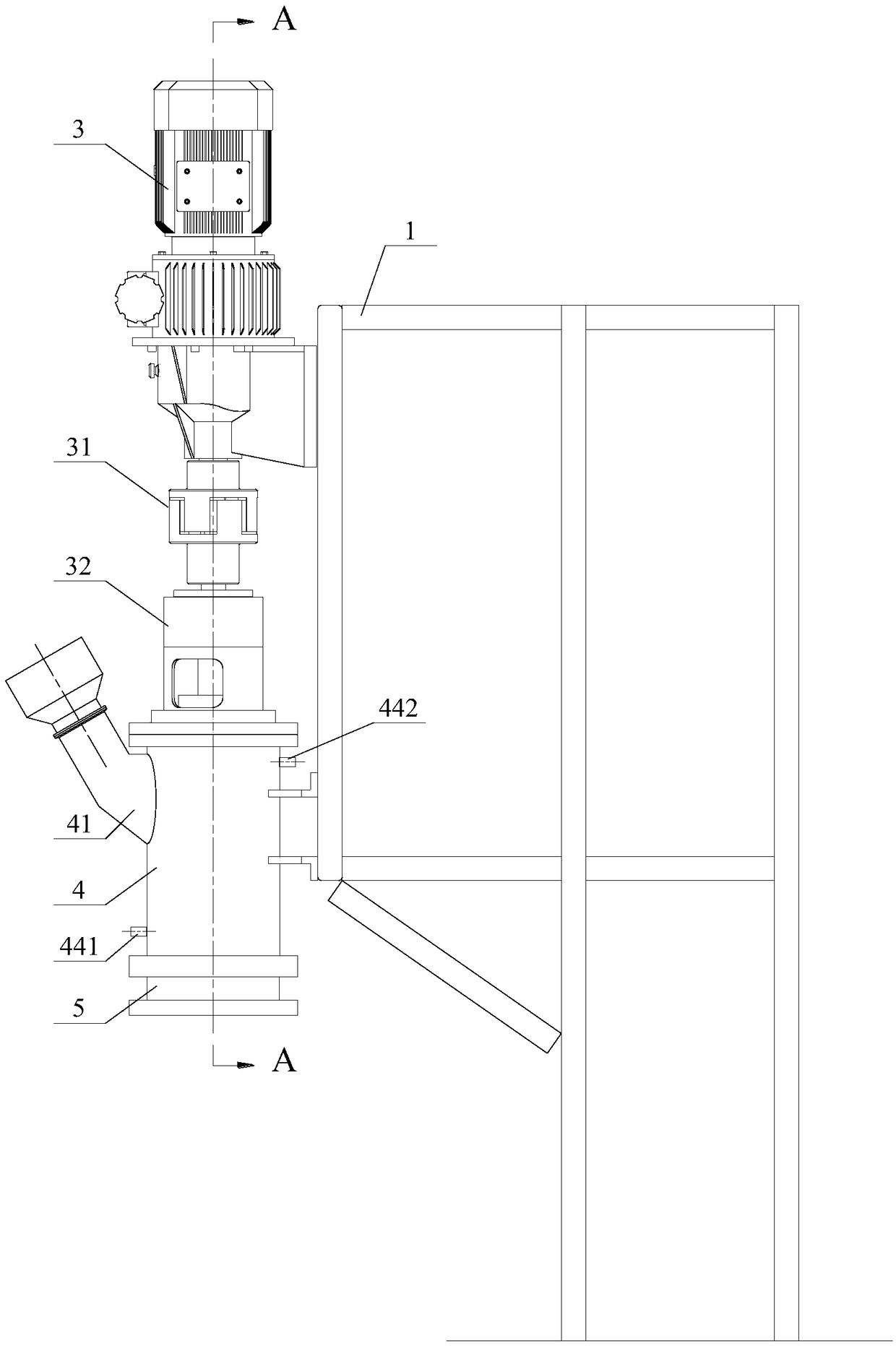

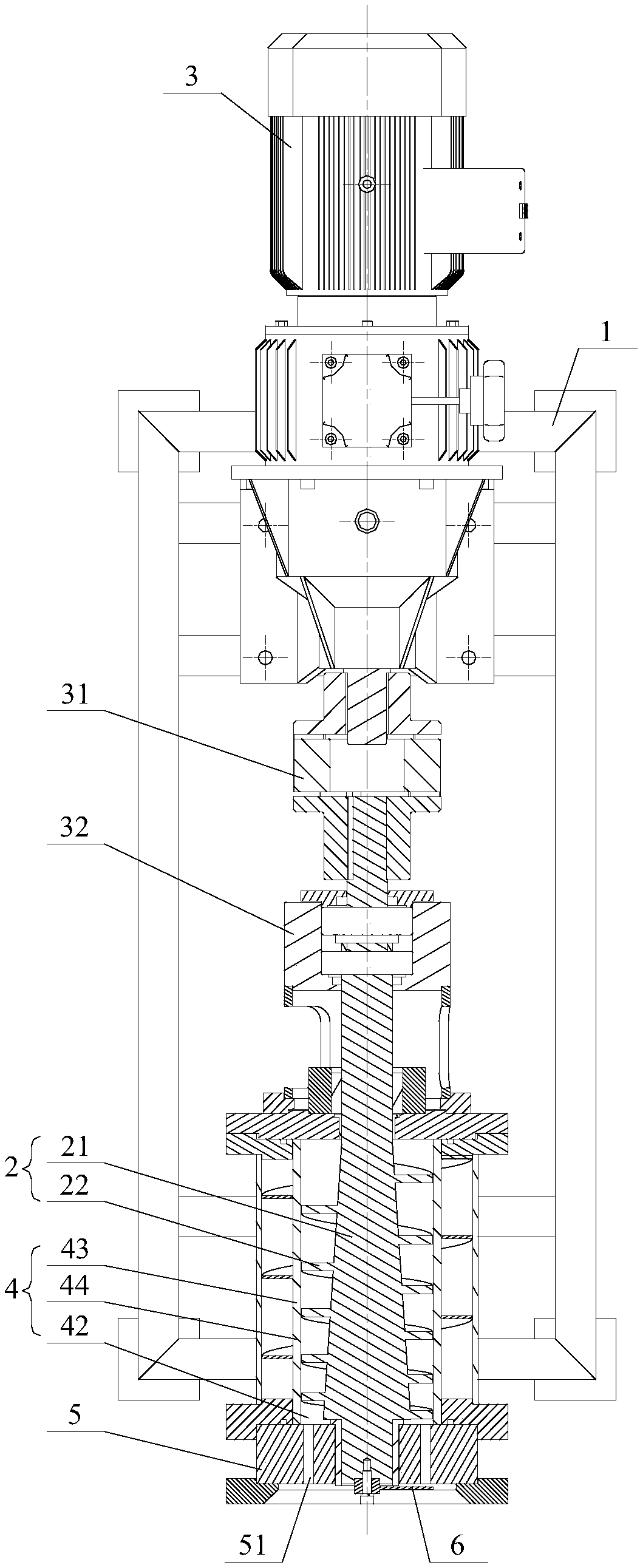

[0034] See figure 1 , which shows a schematic diagram of the overall structure of the device for preparing activated carbon particles according to this embodiment.

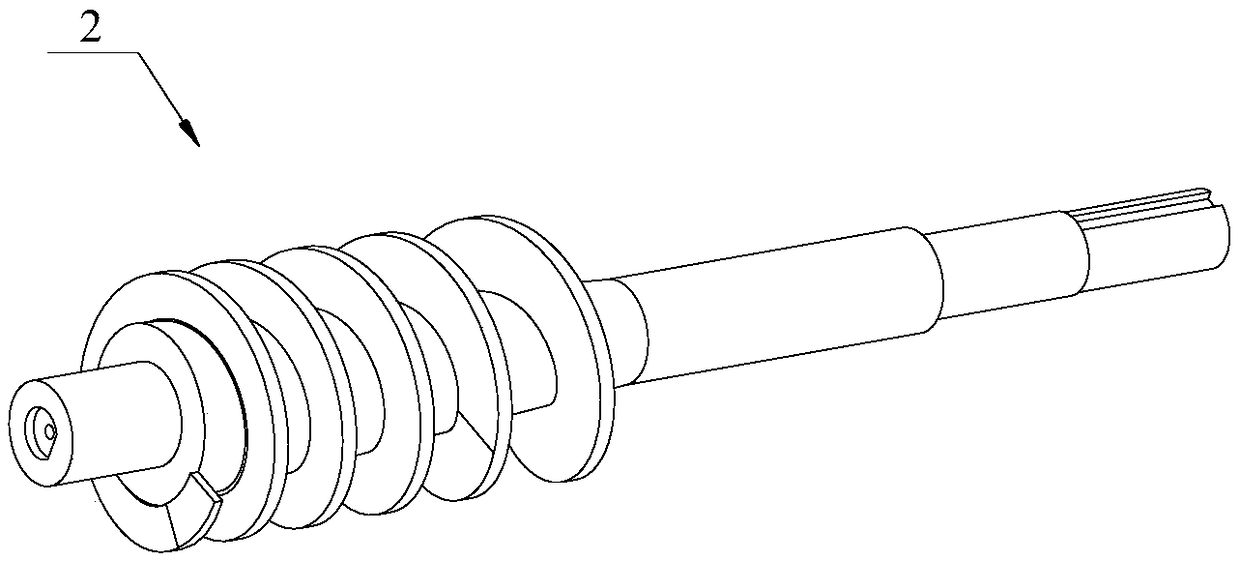

[0035] This activated carbon granule preparation device comprises as the frame 1 that device constitutes bearing support, as figure 1 As shown, the frame 1 is provided with a driving component for driving the extrusion auger 2, preferably a motor 3; its forming cavity 4 has a material cavity 43 and a material inlet 41 and a material outlet 42 connected thereto. Wherein, the extrusion auger 2 is inserted in the molding cavity 4, the rotating shaft 21 of the extrusion auger 2 can be connected with the output end of the motor 3, and the rotating shaft 21 in the molding cavity 4 has a helical blade 22, And it is configured such that along the pushing direction of the material, the extrusion ratio formed in the material chamber 43 tends to gradually increase. Here, "extrusion ratio" refers to the ratio of the density...

Embodiment 2

[0046] The difference between this solution and the activated carbon granule preparation device described in Example 1 is that the screw blade 22 of the extrusion auger 2 is a segmented detachable connection structure. See Image 6 , which shows an exploded schematic diagram of the assembly of the extrusion auger. In order to clearly show the difference and connection between this solution and the embodiment, the same functional components in the figure are shown with the same symbols. like Image 6 As shown, the segmented detachable connection structure is specifically configured as follows: the helical blade 22 includes three blade body sleeves arranged in sequence along the length direction of the rotating shaft 21; each blade body sleeve includes a connecting sleeve 221 sleeved on the rotating shaft 21, And the blade body 222 placed on the outer surface of the corresponding connection sleeve 221 .

[0047] Wherein, there is a circumferential limiting pair between the con...

Embodiment 3

[0052] The difference between this solution and the device for preparing activated carbon granules described in Example 1 or Example 2 is that the output die 5 is optimized and improved. See Figure 7 and Figure 8 ,in, Figure 7 It is a schematic diagram of the assembly explosion of the discharge die described in this scheme, Figure 8 for Figure 7 A cross-sectional view of the discharge die shown in . In order to clearly show the differences and connections between this solution and the embodiments, the same functional components in the figure are shown with the same symbols.

[0053] As shown in the figure, the discharge die 5 includes a substrate 52 and a plurality of wear-resistant sleeves 53, and the substrate 52 is provided with a plurality of insertion holes 521. Obviously, the arrangement of the insertion holes 521 corresponds to that of the die holes 51. quantity and arrangement. Each wear-resistant sleeve 53 is inserted into the corresponding insertion hole 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com