Tin bath structure for forming of high-borosilicate float glass

A technology of float glass and high borosilicate, applied in the field of glass processing and forming, can solve the problems of poor surface flatness, low glass quality, difficult flow control, etc., and achieve the effect of simple structure, strong practicability, and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

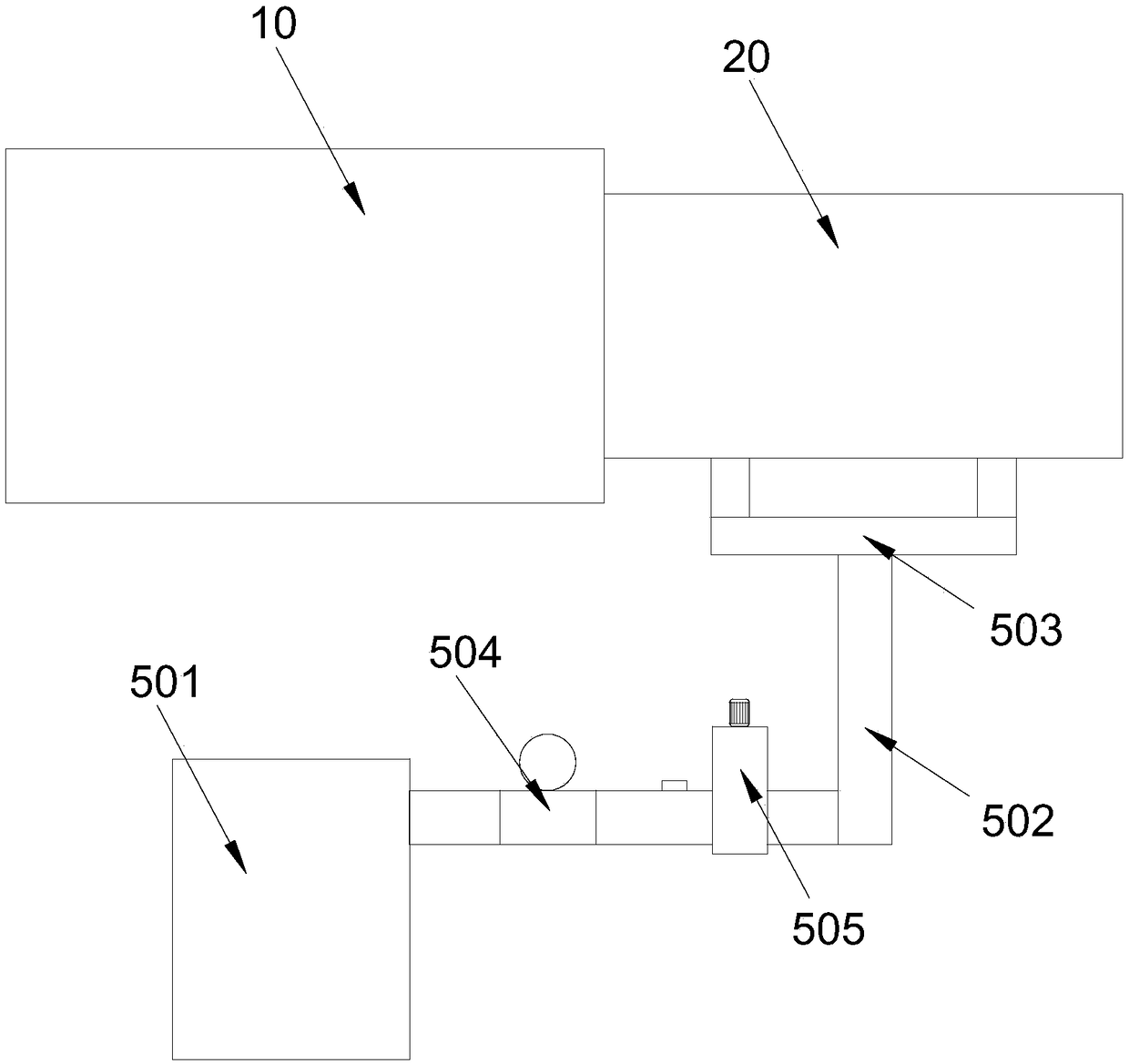

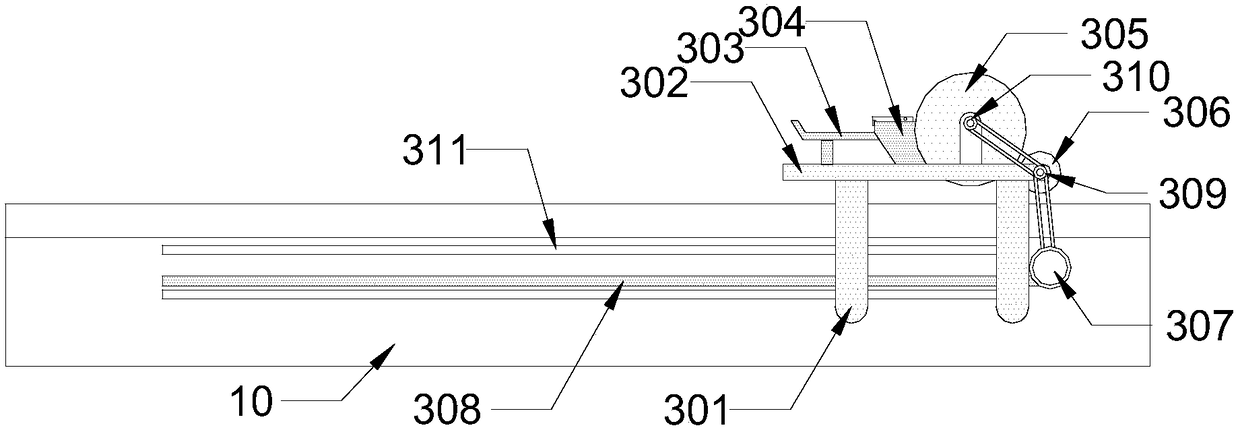

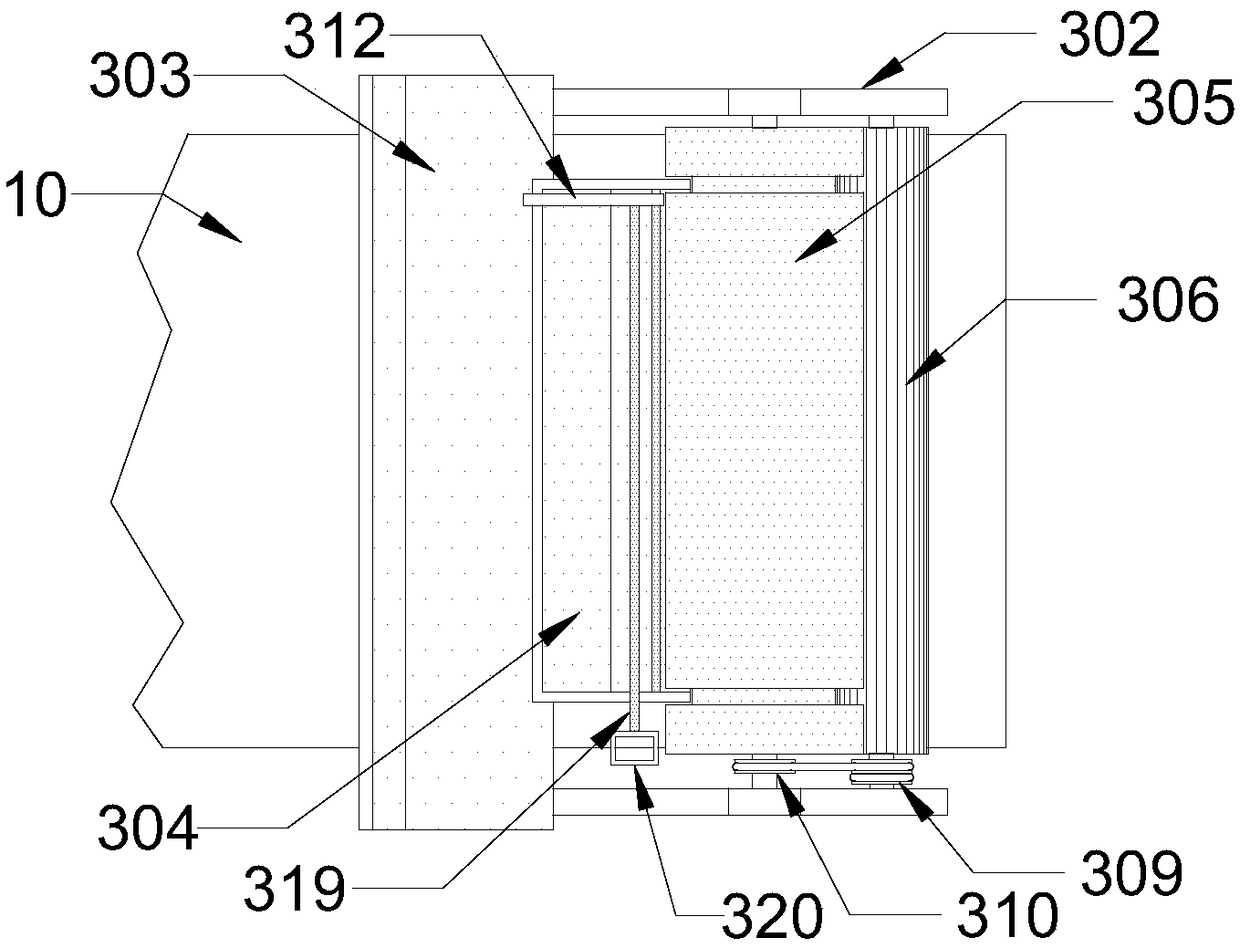

[0032] Such as figure 1 and 11 As shown, the tin bath structure for forming high borosilicate float glass includes glass forming processing table 10, transition roller table 20 conveyed after forming, flattening device 30 for controlling the surface during forming, and slag removal of processing table 10 before forming The device 40 and the gas conveying device 50 for conveying the protective gas during the transmission process, the center of the top surface of the processing table 10 is provided with a rectangular tin tank 111, the discharge end of the processing table 10 and the transition roller table 20 feed end Horizontally fixed connection, the leveling device 30 is arranged on the top surface of the processing table 10 and is slidably connected with the processing table 10, and the slag removal device 40 is also arranged on the top surface of the processing table 10 and is slidably connected with the processing table 10, so The gas conveying device 50 communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com