Method for degrading organic tin in water body

A technology of organotin and water, which is applied in the field of organotin degradation, can solve the problems of inaccurate control of temperature, insufficient pressure reduction, and errors in increasing readings, and achieve the goal of no secondary pollution at cost, reduction of random noise, and realization of temperature compensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

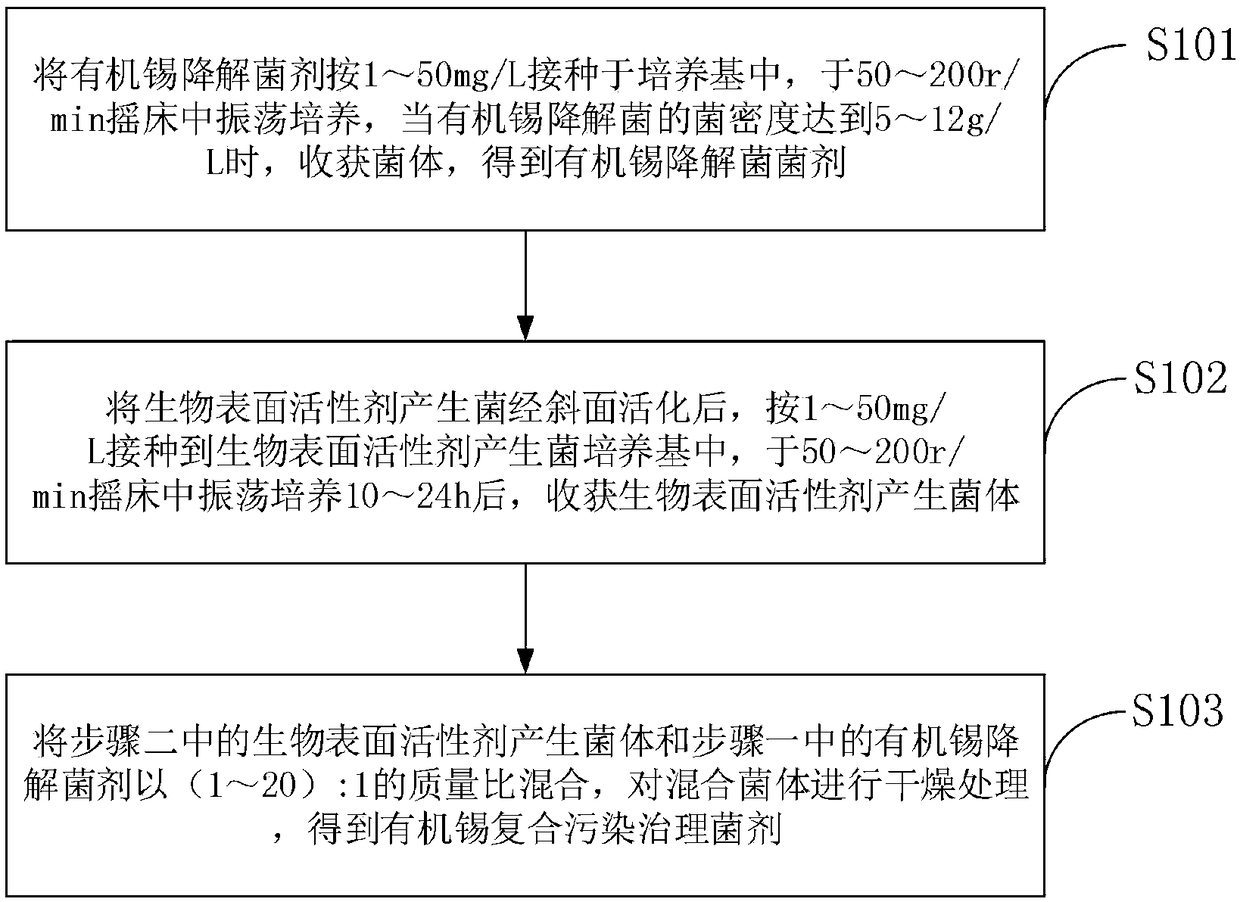

[0085] A method for degrading organotin in water is:

[0086] Step 1: inoculate the organotin-degrading bacteria into the culture medium at 1-50 mg / L, shake and cultivate in a shaker at 50-200 r / min, and harvest when the density of the organotin-degrading bacteria reaches 5-12 g / L Bacteria to obtain organotin-degrading bacterial agent;

[0087] Step 2: After the biosurfactant-producing bacteria are activated on a slant, they are inoculated into the medium of biosurfactant-producing bacteria at 1-50 mg / L, shaken and cultivated in a shaker at 50-200 r / min for 10-24 hours, and then harvested Biosurfactant producing bacteria;

[0088] Step 3: Mix the biosurfactant producing bacterium in step 2 with the organotin degrading bacterium in step 1 in a mass ratio of 5:1, and dry the mixed bacterium to obtain the organotin composite pollution control bacterium .

Embodiment 2

[0090] A method for degrading organotin in water is:

[0091] Step 1: inoculate the organotin-degrading bacteria into the culture medium at 1-50 mg / L, shake and cultivate in a shaker at 50-200 r / min, and harvest when the density of the organotin-degrading bacteria reaches 5-12 g / L Bacteria to obtain organotin-degrading bacterial agent;

[0092] Step 2: After the biosurfactant-producing bacteria are activated on a slant, they are inoculated into the medium of biosurfactant-producing bacteria at 1-50 mg / L, shaken and cultivated in a shaker at 50-200 r / min for 10-24 hours, and then harvested Biosurfactant producing bacteria;

[0093] Step 3: Mix the biosurfactant producing bacterium in step 2 with the organotin degrading bacterium in step 1 at a mass ratio of 10:1, and dry the mixed bacterium to obtain the organotin composite pollution control bacterium .

Embodiment 3

[0095] A method for degrading organotin in water is:

[0096] Step 1: inoculate the organotin-degrading bacteria into the culture medium at 1-50 mg / L, shake and cultivate in a shaker at 50-200 r / min, and harvest when the density of the organotin-degrading bacteria reaches 5-12 g / L Bacteria to obtain organotin-degrading bacterial agent;

[0097] Step 2: After the biosurfactant-producing bacteria are activated on a slant, they are inoculated into the medium of biosurfactant-producing bacteria at 1-50 mg / L, shaken and cultivated in a shaker at 50-200 r / min for 10-24 hours, and then harvested Biosurfactant producing bacteria;

[0098] Step 3: Mix the biosurfactant producing bacterium in step 2 with the organotin degrading bacterium in step 1 in a mass ratio of 20:1, and dry the mixed bacterium to obtain the organotin composite pollution control bacterium .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com