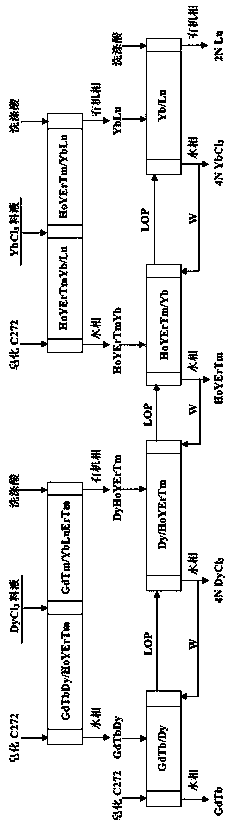

Extraction and separation method for co-producing 4N dysprosium and 4N ytterbium

A separation method and extraction technology, which are applied in the field of preparing 4N-grade dysprosium chloride and 4N-grade ytterbium chloride by fractionation extraction method, can solve the problems of low qualification rate of 4N-grade products, poor process stability, low acid-base consumption, etc. The effect of increasing the rate, reducing the consumption of acid and alkali, and reducing the consumption of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The saponified C272 organic phase is 30% by volume of C272 in the kerosene solution of the extractant C272, and the saponification rate is 36%.

[0032] The pH of the 2N-grade dysprosium chloride solution is 3, and the concentrations of rare earth elements are: Gd 0.030g / L, Tb 0.20g / L, Dy160.0g / L, Ho 0.30g / L, Y 0.10g / L, Er 0.060g / L, Tm 0.030g / L.

[0033] The enrichment thulium ytterbium lutetium chloride solution has a pH of 3, and the concentrations of rare earth elements are: Ho 0.040g / L, Y 0.20g / L, Er 2.0g / L, Tm 16.0g / L, Yb 130.0g / L, Lu 18.0g / L.

[0034] Step 1: Fractional distillation and extraction to separate GdTbDy / DyHoYErTm

[0035] The saponified C272 organic phase is used as the extraction organic phase, the 2N grade dysprosium chloride solution is used as the first feed solution, and 3.0mol / L HCl is used as the washing acid. The saponified C272 organic phase enters the GdTbDy / DyHoYErTm fractionation extraction system from the first stage, the first feed l...

Embodiment 2

[0050] The saponified C272 organic phase is 30% by volume of C272 in the kerosene solution of the extractant C272, and the saponification rate is 36%.

[0051] The pH of the 2N-grade dysprosium chloride solution is 2, and the concentrations of rare earth elements are: Gd 0.050g / L, Tb 0.40g / L, Dy165.0g / L, Ho 0.70g / L, Y 0.20g / L, Er 0.10g / L, Tm 0.050g / L.

[0052] The enrichment thulium ytterbium lutetium chloride solution has a pH of 4, and the concentrations of rare earth elements are: Ho 0.0060g / L, Y 0.30g / L, Er 3.0g / L, Tm 18.0g / L, Yb 125.0g / L, Lu 20.0g / L.

[0053] Step 1: Fractional distillation and extraction to separate GdTbDy / DyHoYErTm

[0054] The saponified C272 organic phase is used as the extraction organic phase, the 2N grade dysprosium chloride solution is used as the first feed solution, and 3.0mol / L HCl is used as the washing acid. The saponified C272 organic phase enters the GdTbDy / DyHoYErTm fractionation extraction system from the first stage, the first feed l...

Embodiment 3

[0069] The saponified C272 organic phase is 30% by volume of C272 in the kerosene solution of the extractant C272, and the saponification rate is 36%.

[0070] The pH of the 2N grade dysprosium chloride solution is 4, and the concentrations of rare earth elements are: Gd 0.010g / L, Tb 0.050g / L, Dy155.0g / L, Ho 0.10g / L, Y 0.050g / L, Er 0.020g / L, Tm 0.010g / L.

[0071] The enrichment thulium ytterbium lutetium chloride solution has a pH of 2, and the concentrations of rare earth elements are: Ho 0.0020g / L, Y 0.10g / L, Er 1.0g / L, Tm 14.0g / L, Yb 135.0g / L, Lu 16.0g / L.

[0072] Step 1: Fractional distillation and extraction to separate GdTbDy / DyHoYErTm

[0073] The saponified C272 organic phase is used as the extraction organic phase, the 2N grade dysprosium chloride solution is used as the first feed solution, and 3.0mol / L HCl is used as the washing acid. The saponified C272 organic phase enters the GdTbDy / DyHoYErTm fractionation extraction system from the first stage, the first fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com